On-site assembling type extending arm combined node

A technology for on-site assembly and combination of nodes, which is applied in the direction of architecture and building structure, can solve the problems of insufficient rigidity, difficult construction, high cost, etc., and achieve the effects of good plasticity and toughness, fast construction speed and good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in combination with technical solutions and with reference to the accompanying drawings.

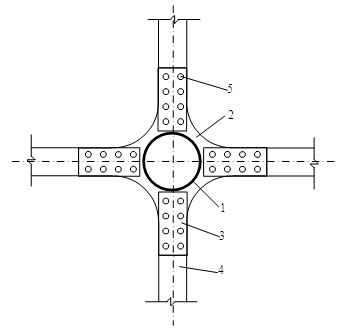

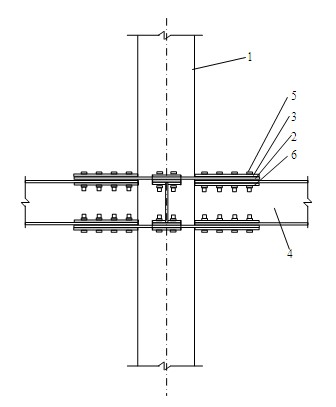

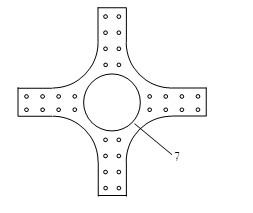

[0015] The site-assembled outrigger composite node proposed by the present invention is as follows: Figure 1~Figure 6 shown.

[0016] The whole device is mainly composed of steel pipe concrete column 1, outrigger H-shaped steel beam mounting plate 2, outrigger outer backing plate 3, H-shaped steel beam 4, M20 high-strength bolt 5, H-shaped steel beam inner backing plate 6, cross Type node outrigger H-shaped steel beam mounting plate 7, T-shaped node outrigger H-shaped steel beam mounting plate 8, straight node outrigger H-shaped steel beam mounting plate 9, L-shaped node outrigger H-type Steel girder installation plate 10 etc. are formed.

[0017] According to different node forms such as the middle column of the middle frame, the side column of the middle frame, the middle column of the side frame and the side column of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com