Process for preparing building template by using fly ash and prepared building template

A technology of building formwork and fly ash, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of complex binder system, high carbon content, high cost, etc., and achieve low production cost, Pollution reduction, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

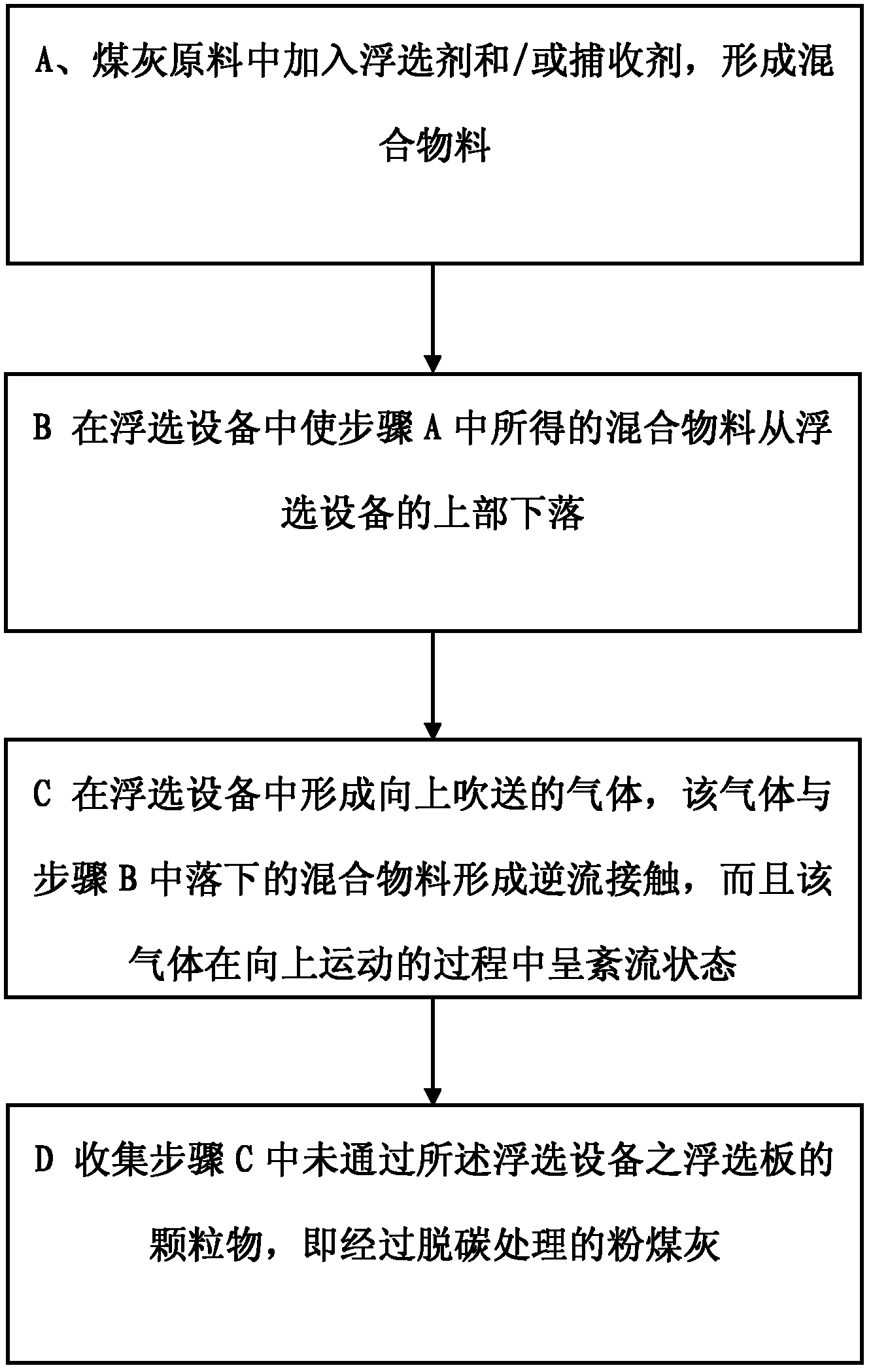

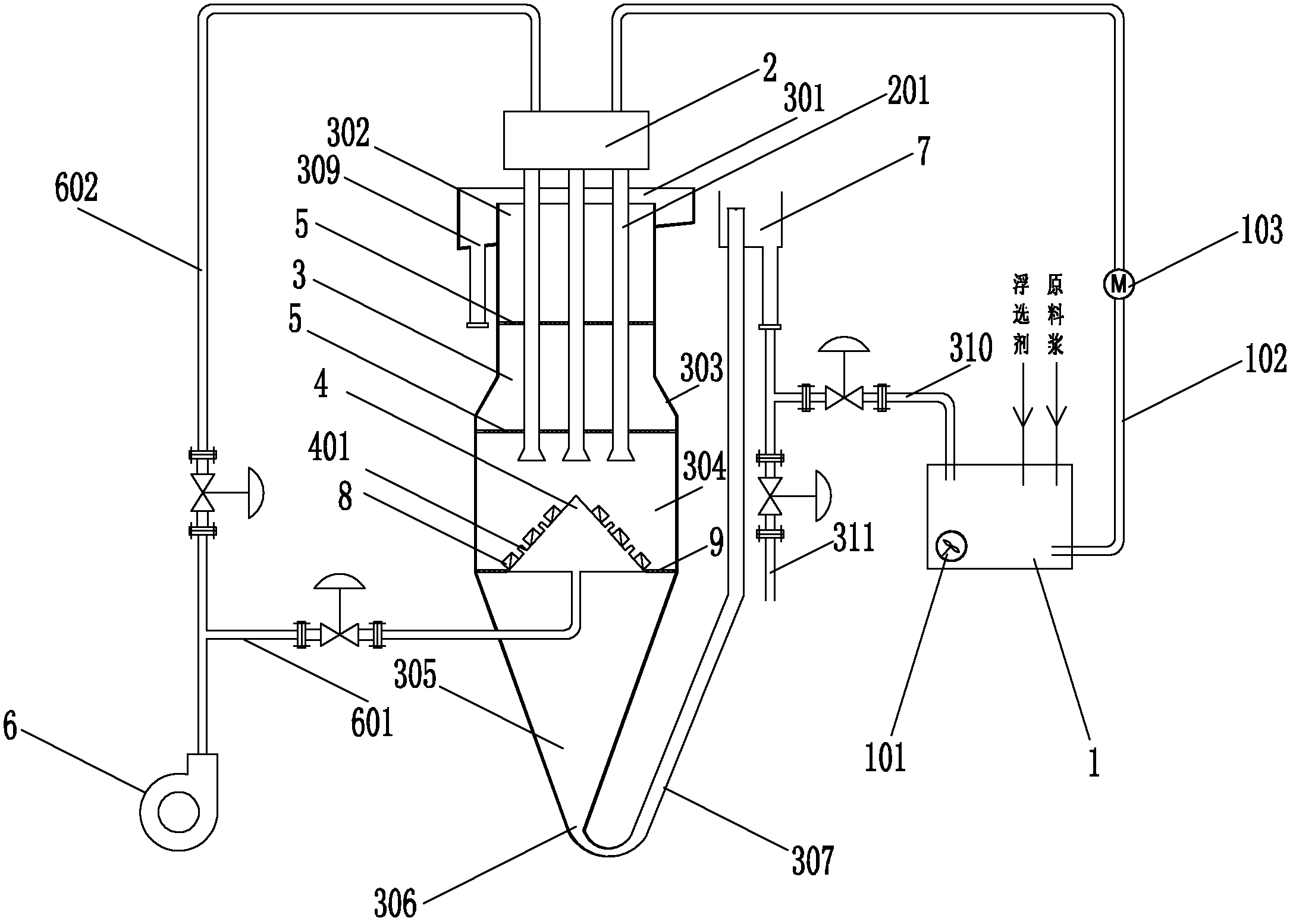

[0051] In this embodiment, fly ash is used to manufacture building formwork, and the fly ash used is the fly ash of a circulating fluidized bed boiler, which is in the form of sponge floc. The fly ash includes: 48%-52% silicon dioxide, 6%-7% calcium oxide, 20%-28% aluminum oxide, 5%-7.2% ferric oxide, 1.8%- 2.1% magnesium oxide, 1%-1.25% sulfur trioxide, the loss on ignition is 6%-8%, and the carbon content is 10%-12%. The fly ash is decarburized so that its carbon content is not higher than 5% before building formwork is manufactured. Such as figure 1 As shown, the decarburization process includes the following steps:

[0052] A, adding flotation agent and / or collector to the fly ash raw material to form a mixed material;

[0053] B, in the flotation equipment, the mixed material obtained in the step A is dropped from the top of the flotation equipment;

[0054] C, forming upward blowing gas in the flotation device, the gas forms countercurrent contact with the mixed mate...

Embodiment 2

[0076] In this embodiment, the fly ash of the circulating fluidized bed boiler after decarburization is used to manufacture building templates, and the process of decarbonization is the same as that of embodiment 1.

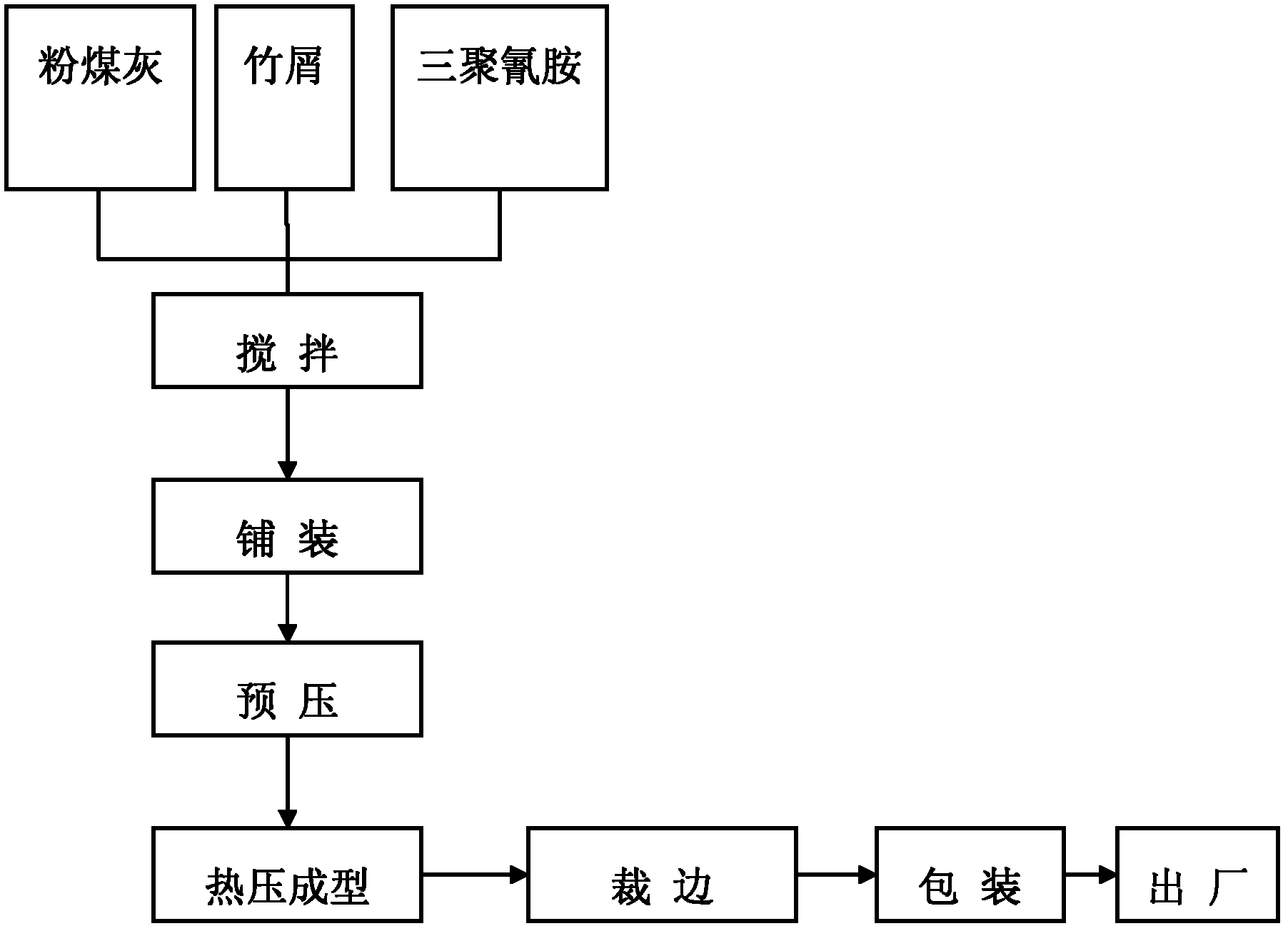

[0077] In this embodiment, the steps of preparing building formwork using decarbonized fly ash are as follows:

[0078] 1. By weight, 45% of fly ash after decarburization, 45% of bamboo chips, and 10% of phenolic resin are mixed;

[0079] ② stirring the mixture obtained in step ①;

[0080] ③After paving the mixture stirred in step ②, pre-press with a pressure of 1.6MPa;

[0081] ④The mixture pre-pressed in step ③ is hot-pressed at 210°C with a pressure of 1.3MPa to a density of 0.90g / cm 3 template.

[0082] Wherein, the particle size of the fly ash in the step 1. is 340 orders, and the bamboo chips are 80 orders.

[0083] The prepared building formwork comprises by weight 45% decarbonized flocculent circulating fluidized bed boiler fly ash, 45% bamboo chips, ...

Embodiment 3

[0086] In this embodiment, the fly ash of the circulating fluidized bed boiler after decarburization is used to manufacture building templates, and the process of decarbonization is the same as that of embodiment 1.

[0087] In this embodiment, the steps of preparing building formwork using decarbonized fly ash are as follows:

[0088] 1. By weight, 58% of fly ash after decarburization, 30% of bamboo chips, and 12% of phenolic resin are mixed;

[0089] ② stirring the mixture obtained in step ①;

[0090] ③After paving the mixture stirred in step ②, pre-press with a pressure of 2.0MPa;

[0091] ④The mixture pre-pressed in step ③ was hot-pressed at 195°C with a pressure of 1.25MPa to form a template.

[0092] The prepared building formwork comprises 58% of decarbonized flocculent circulating fluidized bed boiler fly ash, 30% of bamboo chips and 12% of phenolic resin adhesive by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com