Thermal barrier coating system

A thermal barrier coating and coating technology, which is applied in the fields of power, material preparation, aerospace, aviation, and energy, can solve problems such as damage and failure of the interface between the ceramic layer and the bonding layer, increase the ability to ease thermal mismatch, improve Good interface bonding strength and thermal barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

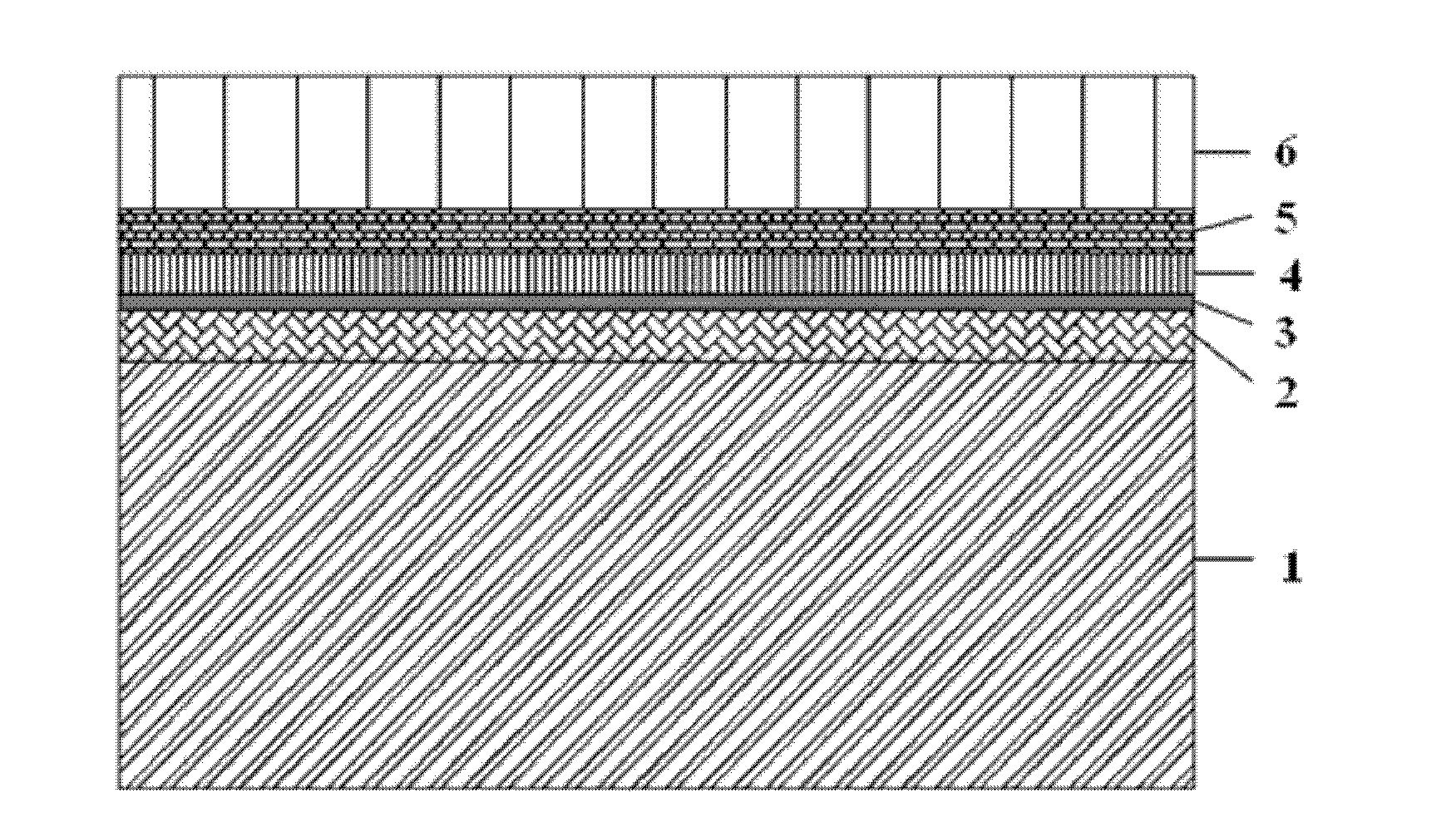

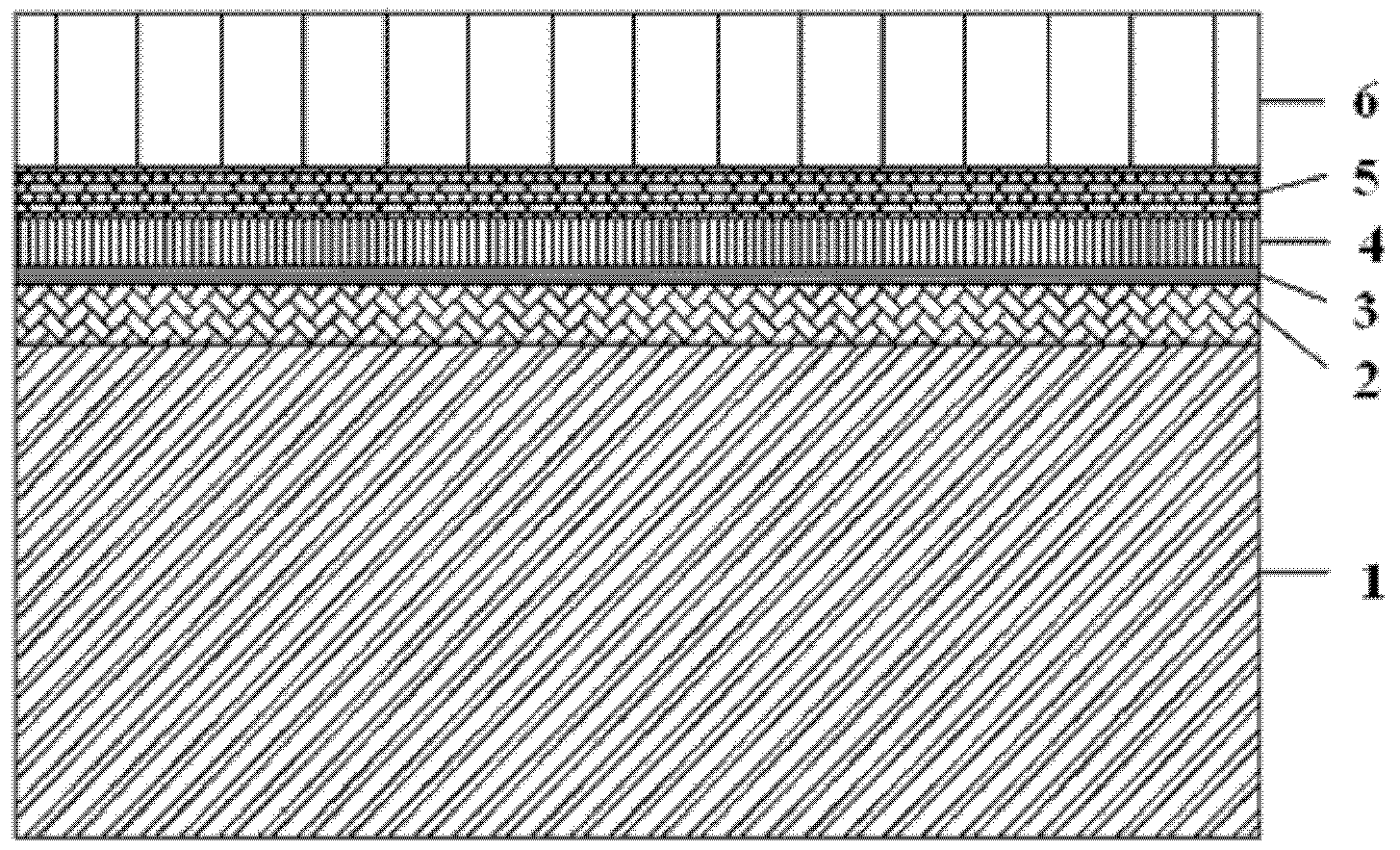

[0022] see figure 1 As shown, the patent invention discloses a thermal barrier coating system, which includes an adhesive layer 2 and a ceramic coating layer prepared sequentially on a substrate 1 . The ceramic coating mainly includes a toughened and heat-insulating layer 6 , a strengthening layer 4 , and a transition layer 5 between the two layers; The material of the ceramic coating is YSZ. By depositing YSZ powder particles on the bonding layer in a completely melted manner, a strengthening layer 4 with a dense columnar crystal structure and high fracture toughness is obtained, and the bonding rate is ≥ 96%; the deposition thickness of the strengthening layer 4 is 30-110 μm, which is vertical The columnar crystal structure on the surface, the grain size is at the nanoscale, and the coating is dense, so as to increase the diffusion resistance of oxygen atoms and en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com