Preparation method for novel drug-loaded chitosan nano-microspheres

A technology of chitosan nano- and drug-loaded microspheres, which is applied in the field of preparation of chitosan drug-loaded microspheres, can solve the problems of unsatisfactory slow-release and controlled-release effects, uneven size, poor dispersion, etc., and achieve sustained release Effective, easy to remove, good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

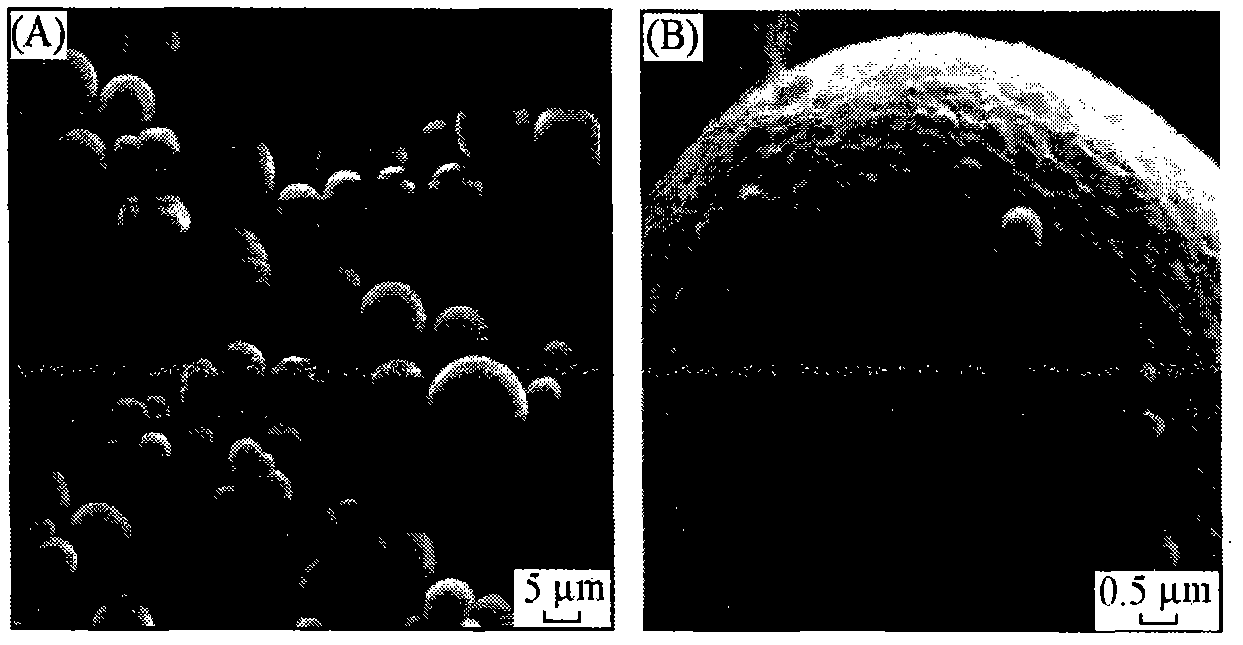

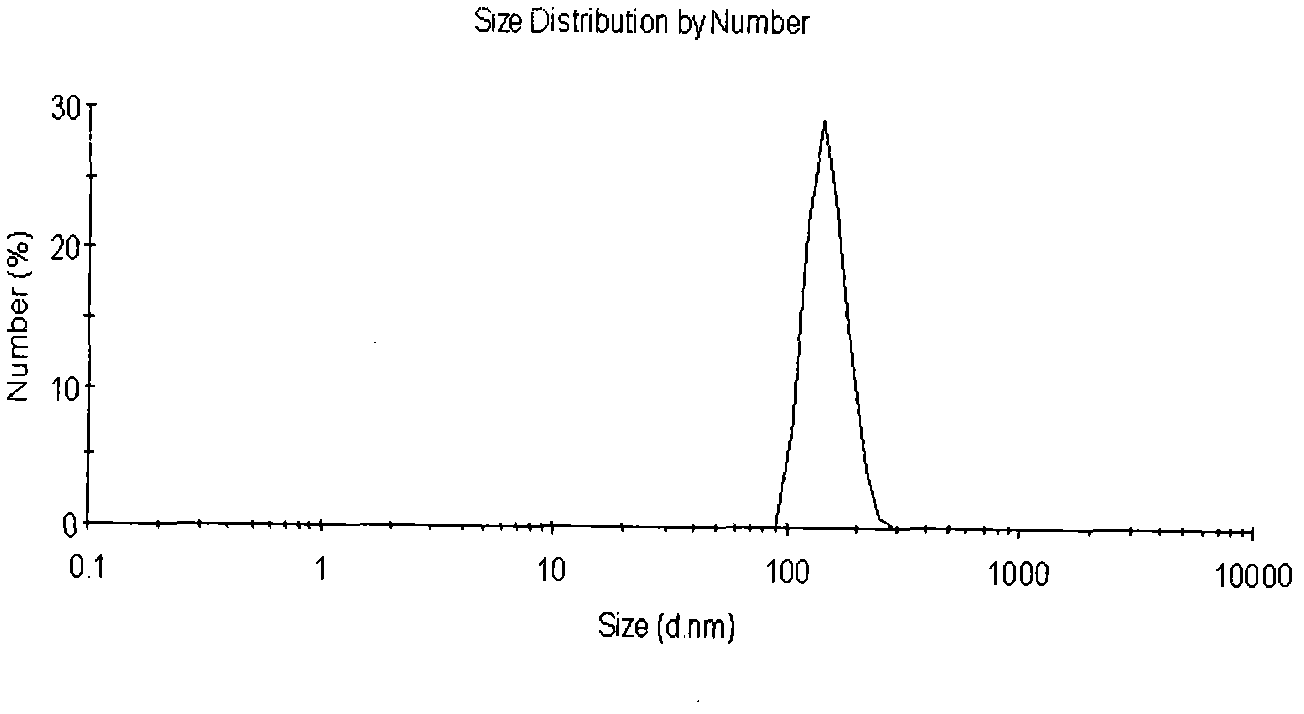

Embodiment 1

[0028] First, dissolve 100mg of chitosan with a viscosity of 300mpa.s and a degree of deacetylation of ≥90% and 5mg of pentafluorouracil in 5g of 1% acetic acid solution. After fully dissolving, add slowly as an aqueous phase to 25g containing In the liquid paraffin oil phase of 2% sorbitol sesquioleate, stir quickly at room temperature for 60 minutes to form a white milky water-in-oil (W / O) emulsion; then add 24 g of 2.5% Put vanillin and acetone solution into the reaction system and continue to stir for 5h; finally, centrifuge at 10000rpm for 10min, collect the prepared drug-loaded nanospheres, and wash them thoroughly with petroleum ether and acetone, respectively, and freeze-dry to obtain light Yellow chitosan drug-loaded nanosphere powder. The microsphere has a particle size of 100-150 nm, a good sphericity, an encapsulation rate of 91.9%, and a drug loading rate of 21.8%.

Embodiment 2

[0030] First, dissolve 200mg of chitosan with a viscosity of 300mpa.s and a degree of deacetylation of ≥90% and 20mg of pentafluorouracil in 10g of a 1% acetic acid solution. After fully dissolving, add slowly as an aqueous phase to 50g containing In the liquid paraffin oil phase of sorbitan sesquioleate with a mass fraction of 2%, quickly stir at room temperature for 60 minutes to form a white milky water-in-oil (W / O) emulsion; then add 40g of 2.5% by mass Put vanillin and acetone solution into the reaction system and continue to stir for 5h; finally, centrifuge at 10000rpm for 10min, collect the prepared drug-loaded nanospheres, and wash them thoroughly with petroleum ether and acetone, respectively, and freeze-dry to obtain light Yellow chitosan drug-loaded nanosphere powder. The microsphere has a particle size of 100-150 nm, a good sphericity, an encapsulation rate of 95.7%, and a drug loading rate of 21.4%.

Embodiment 3

[0032] First, dissolve 300mg of chitosan with a viscosity of 300mpa.s and a degree of deacetylation of ≥90% and 30mg of pentafluorouracil in 12g of 1% acetic acid solution. After fully dissolving, add slowly as an aqueous phase to 60g containing In the liquid paraffin oil phase of sorbitan sesquioleate with a mass fraction of 2%, stir quickly at room temperature for 60 minutes to form a white milky water-in-oil (W / O) emulsion; then add 48g of a 2.5% mass fraction Put vanillin and acetone solution into the reaction system and continue to stir for 5h; finally, centrifuge at 10000rpm for 10min, collect the prepared drug-loaded nanospheres, and wash them thoroughly with petroleum ether and acetone, respectively, and freeze-dry to obtain light Yellow chitosan drug-loaded nanosphere powder. The microsphere has a particle size of 100-150 nm, a good sphericity, an encapsulation rate of 92.5%, and a drug loading rate of 19.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com