Optical transparent pressure-sensitive adhesive material, optical transparent pressure-sensitive adhesive laminate, and process for producing same

一种粘合体、层叠体的技术,应用在化学仪器和方法、光学、非线性光学等方向,能够解决难以实现剥离选择性、剥离强度变大等问题,达到优异选择剥离性、降低气泡产生和剥离、量产性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

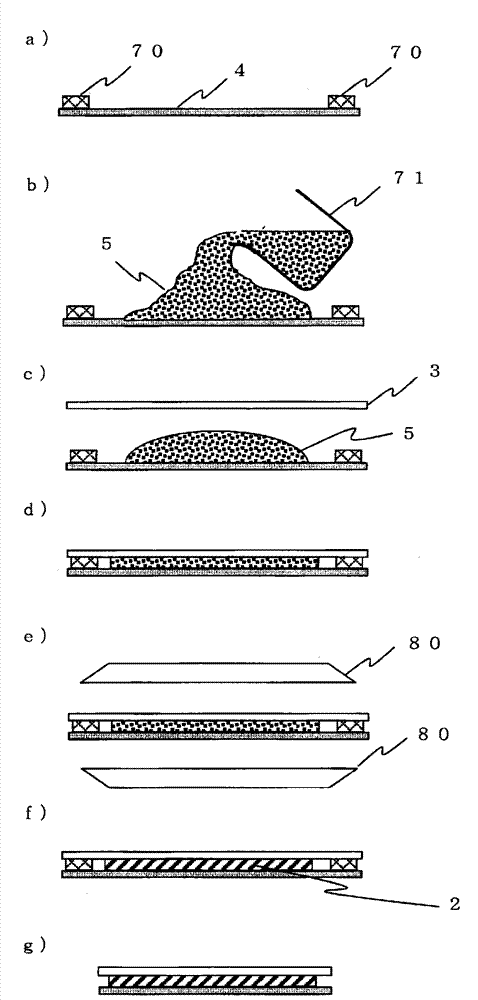

[0169] Through (i) a molding process of sandwiching the uncured liquid silicone gel raw material with a release film (A) and a release film (B), and setting the thickness; (ii) a heating process of heating and curing after molding; and (iii) A cooling step of cooling the solidified sheet to obtain a transparent adhesive laminate for optics of 200 mm x 200 mm x thickness 2.0 mm, in which the release film (A), the optical transparent adhesive, and the release film (B) were sequentially laminated.

[0170] As the uncured liquid silicone gel raw material, a two-component addition reaction silicone gel manufactured by Wacker Asahikasei Silicone Co., Ltd. (model: SLJ3363, total light transmittance in air of 90%) was used. A silicone gel obtained by blending liquid A (main ingredient + crosslinking catalyst) / liquid B (main ingredient + crosslinking agent) at 55 parts by weight / 45 parts by weight.

[0171] The release film (A) uses the following material: it is a structure in which a ...

Embodiment 2

[0176] For the raw material of the uncured liquid silicone gel, a two-component addition reaction silicone gel manufactured by Wacker Asahikasei Silicone Co., Ltd. (model: SLJ3363, the total light transmittance in air is 90%) According to A liquid (main agent + crosslinking catalyst) / B liquid (main agent + crosslinking agent) is 52 parts by weight / 48 parts by weight for use, the respective A sheet-shaped transparent adhesive laminate for optics was obtained in the same manner as in Example 1 except that the addition amount of ethylene bisoleic acid amide was 3% by weight and 2% by weight.

Embodiment 3

[0178] After (i) supplying the uncured liquid viscoelastic material on the peeling film (B), and setting the molding process of thickness; (ii) opening the heating step of heating and curing without sticking the peeling film (A) after molding; (iii) a cooling step of cooling the solidified sheet obtained in the above heating and curing step; and (iv) a peeling film sticking step of sticking a release film (A) on the surface heated and cured in the above heating step to obtain sequentially laminated sheets. A transparent adhesive laminate for optics having a release film (A), a transparent adhesive for optics, and a release film (B), 200 mm x 200 mm x thickness 2.0 mm.

[0179] In addition, the thickness setting of the forming step of (i) is carried out as follows: the peeling action surface of the release film (B) is laid on a flat glass substrate, and further, the aluminum plate is placed on the release film (B). A frame-shaped spacer with an internal size of 200mm×200mm×thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com