Method for controlling thickness of oxidation film through ion injection process

A technology of ion implantation and oxide film, which is applied in the field of microelectronics, can solve the problems of STI edge depression and affecting device performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0017] A special application using ion implantation process to control the thickness of oxide film, in which,

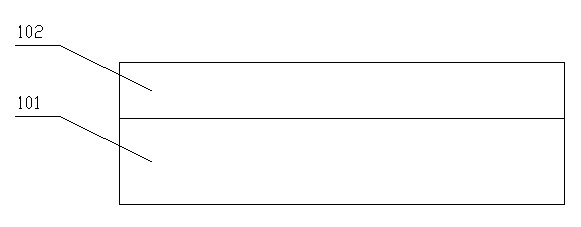

[0018] figure 1 It is a schematic diagram after spin-coating photoresist on the silicon wafer of the method for controlling the thickness of the oxide film through the ion implantation process of the present invention; please refer to figure 1 , spin-coat photoresist 102 on silicon wafer 101;

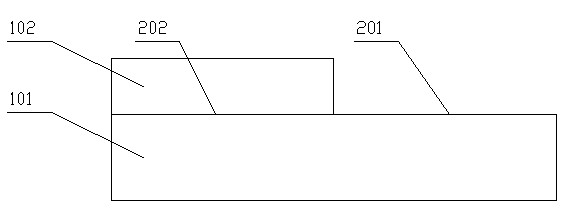

[0019] figure 2 It is a schematic diagram of the method of controlling the thickness of the oxide film through the ion implantation process of the present invention after photolithography opens the thick oxide film region, please refer to figure 2 , the thick oxide film region 201 is opened by photolithography, and the thin oxide film region 202 is covered by the remaining photoresist 102, and the thick oxide film region 201 is exposed so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com