Copper Damascus process MIM (metal-insulator-metal) capacitor structure and manufacturing process

A technology of metal capacitors and insulating layers, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problem of reducing the area of MIM capacitors and achieve the effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0052] A copper damascene process metal-insulation layer-metal capacitor manufacturing method, wherein,

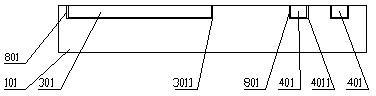

[0053] figure 1 It is a structural schematic diagram of the structure of the copper damascene process metal-insulating layer-metal capacitor and its manufacturing process after forming the first electrode and the metal interconnection line of the present invention, please refer to figure 1 , the first electrode trench 3011 and the metal interconnection trench 4011 are formed by photolithography and etching on the base dielectric layer 101 by the damascene process, the metal barrier layer 801 and the copper seed layer are deposited, and the filling metal copper is electroplated, chemical mechanical Grinding and planarizing to remove excess metal, making the first electrode 301 and the metal interconnection 401;

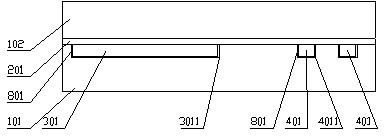

[0054] figure 2 It is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com