Coupling waveguide, manufacture method thereof and semiconductor photoelectronic device applying coupling waveguide

A technology for optoelectronic devices and coupling waveguides, applied in the structure of optical waveguide semiconductors, optical waveguides and optical components, etc., can solve problems such as disadvantage, small driving voltage, weak light absorption at the back end of the waveguide, etc., to improve absorption efficiency, prevent The effect of increasing the driving voltage and preventing excessive photo-generated carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

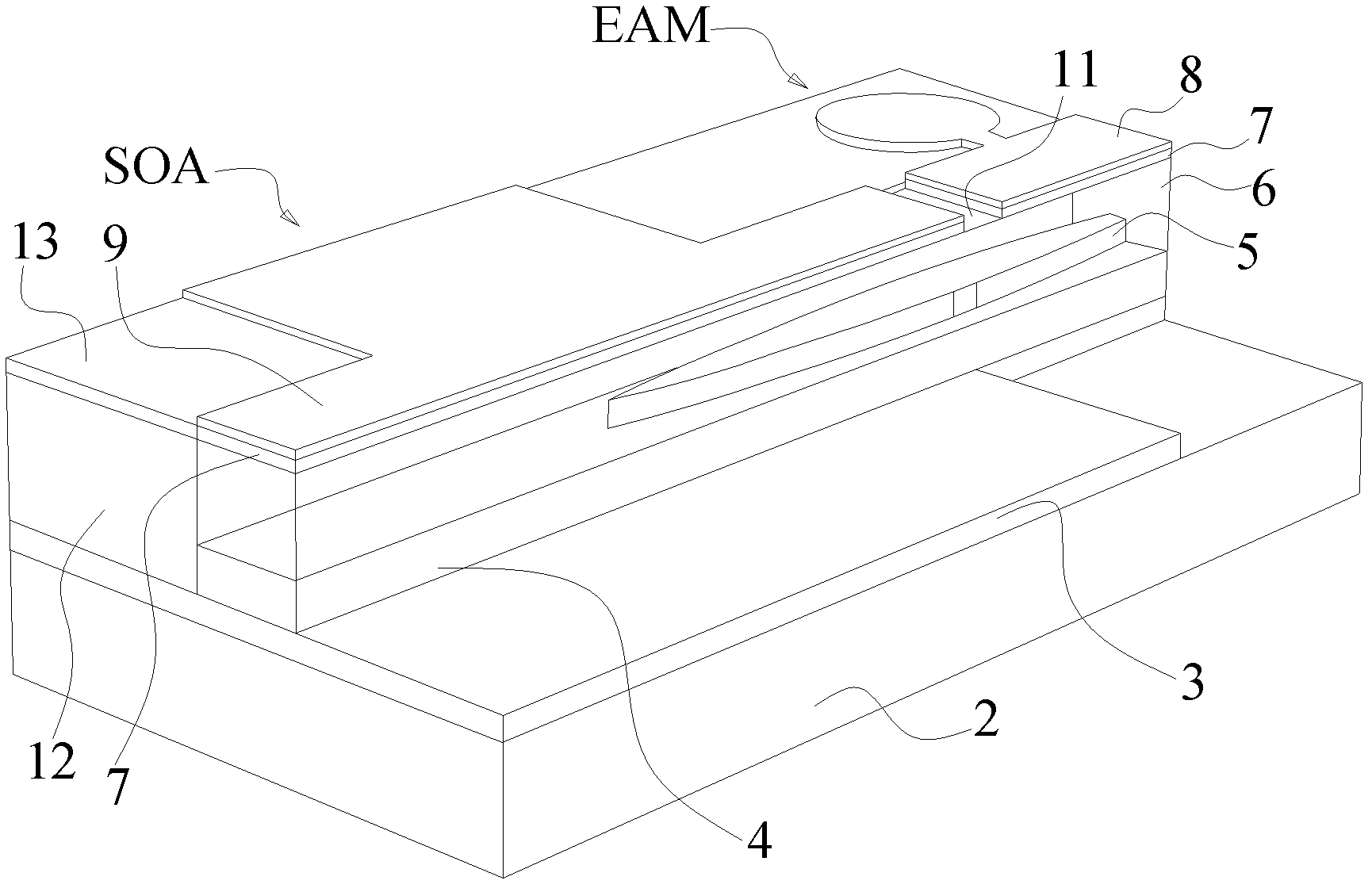

[0034] like figure 1 As shown, the coupling waveguide of this embodiment includes substrates 1 distributed sequentially from bottom to top (substrate 1 is in figure 1 not shown in), the lower waveguide cladding layer 2, the first waveguide core layer 3, the isolation layer 4, the second waveguide core layer 5 and the upper waveguide cladding layer 6, the first waveguide core layer 3 is an active waveguide layer, The second waveguide core layer 5 is a coupling and guiding waveguide layer, the second waveguide core layer 5 has a width gradient section whose lateral width gradually changes along the light guiding direction, and the upper waveguide cladding layer 6 covers the second waveguide core layer 5. The top and sides of the waveguide core layer 5.

[0035] In this embodiment, the lateral width of the width gradient section of the second waveguide core layer 5 first gradually becomes wider and then gradually narrows along the light guiding direction. In other embodiments o...

Embodiment 2

[0039] A method of manufacturing the above coupling waveguide, comprising the following steps:

[0040] S1: Epitaxial growth of the lower waveguide cladding layer 2, the first waveguide core layer 3, the isolation layer 4 and the second waveguide core layer 5 in sequence on a clean epitaxial wafer;

[0041] S2: Processing the second waveguide core layer 5 to form a width gradient section whose lateral width changes along the light guiding direction;

[0042] S3: performing secondary epitaxy to form an upper waveguide cladding layer 6 covering the upper side and side surfaces of the second waveguide core layer 5 .

[0043] In this embodiment, the step of processing the second waveguide core layer 5 includes using electron beam exposure to make a mask on the second waveguide core layer 5, and then performing dry etching first and then wet etching The process of the second waveguide core layer 5. In other embodiments, other methods may also be used to change the lateral width o...

Embodiment 3

[0046] like figure 1 As shown, a semiconductor optoelectronic device having the coupling waveguide described in Embodiment 1, the semiconductor optoelectronic device includes an electro-absorption modulator EAM, and the second waveguide core layer 5 of the coupling waveguide corresponds to the electro-absorption modulator EAM The lateral width of the portion is gradually narrowed along the light guiding direction.

[0047] The semiconductor optoelectronic device also includes a semiconductor optical amplifier SOA sharing the same coupling waveguide with the electro-absorption modulator EAM, and the second waveguide core layer 5 of the coupling waveguide is along the guideway along the lateral width of the corresponding part of the semiconductor optical amplifier SOA. The light direction gradually widens.

[0048] The semiconductor optical amplifier SOA and the electro-absorption modulator EAM are successively arranged adjacent to each other along the light guiding direction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com