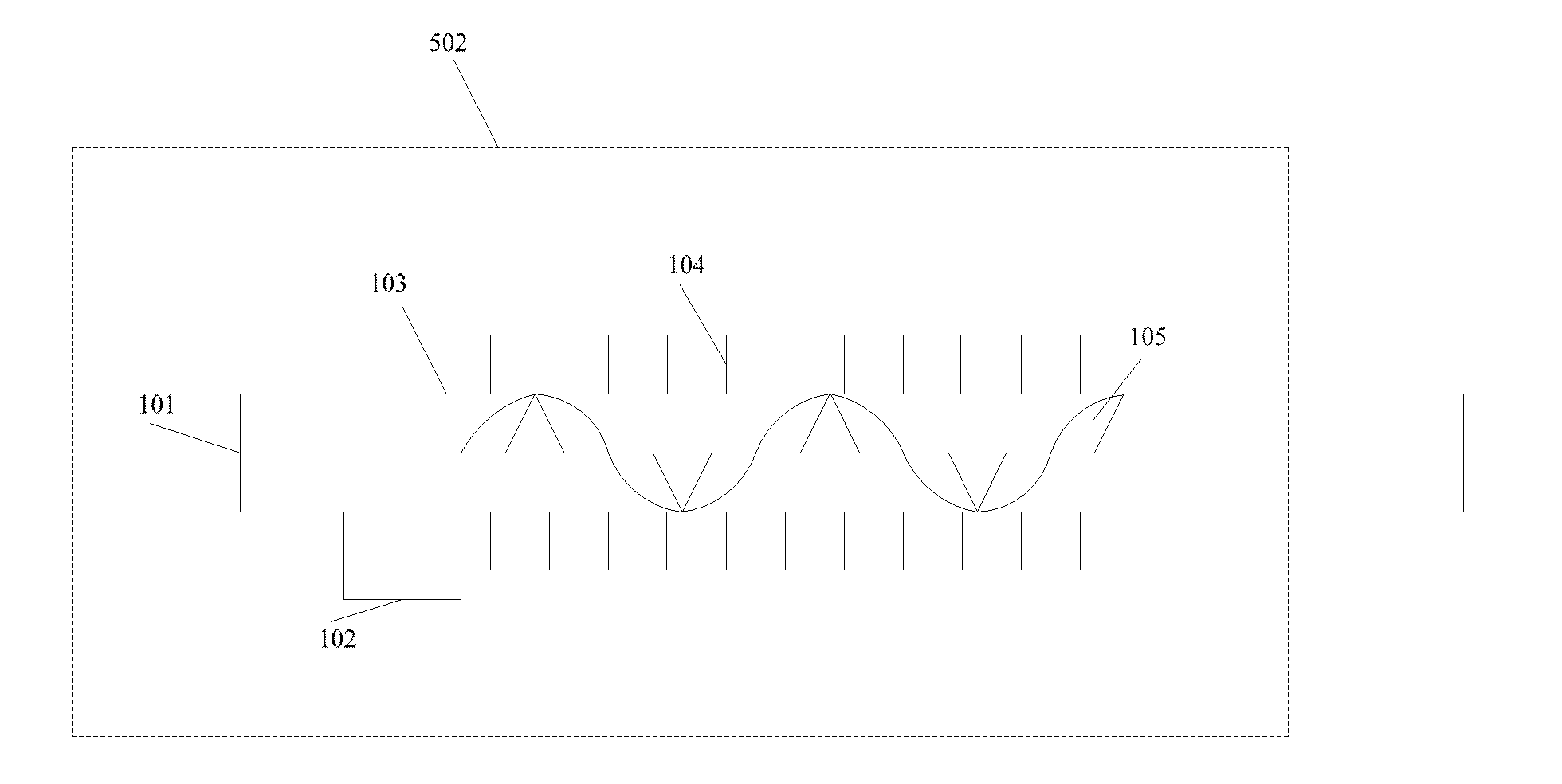

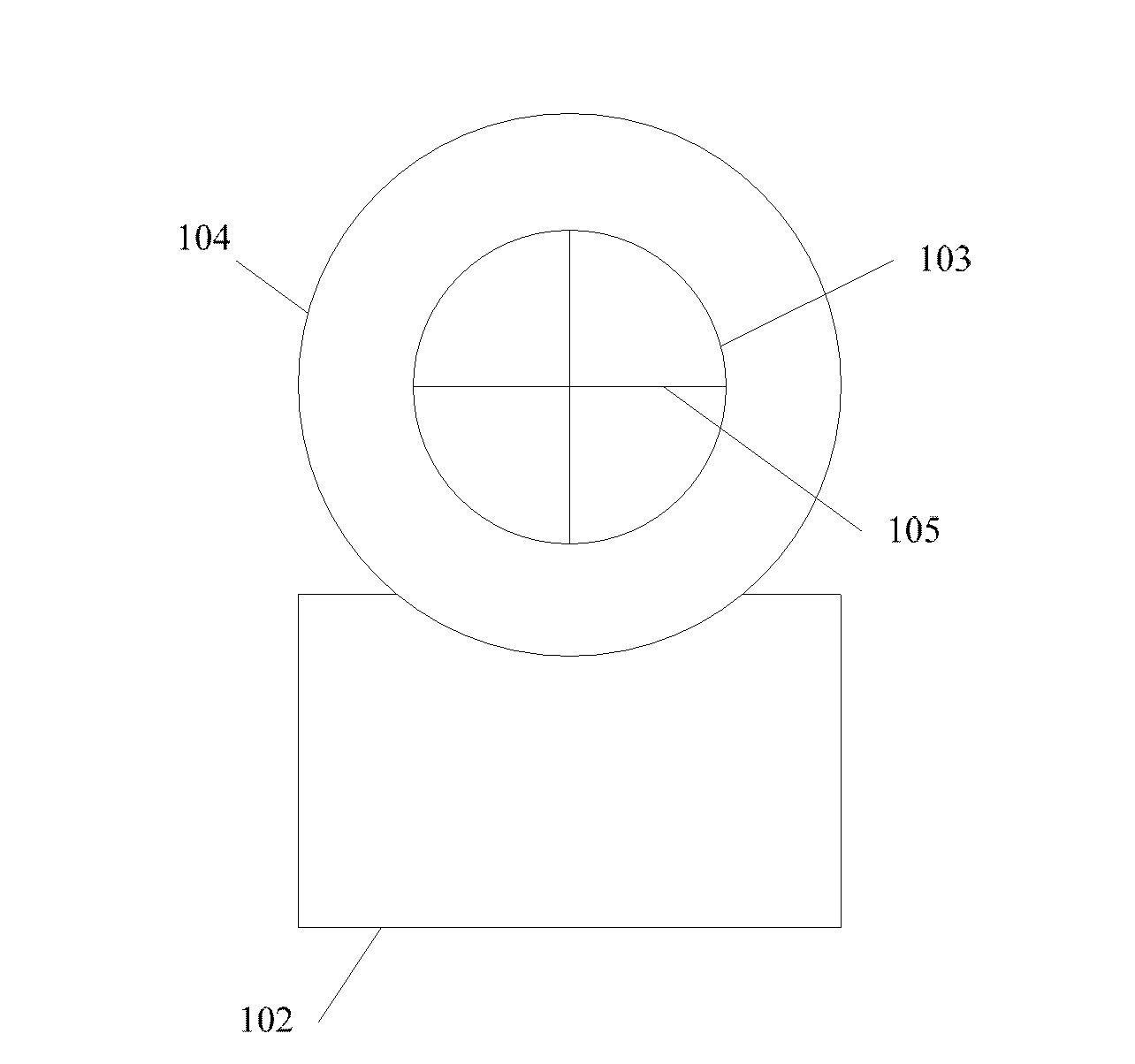

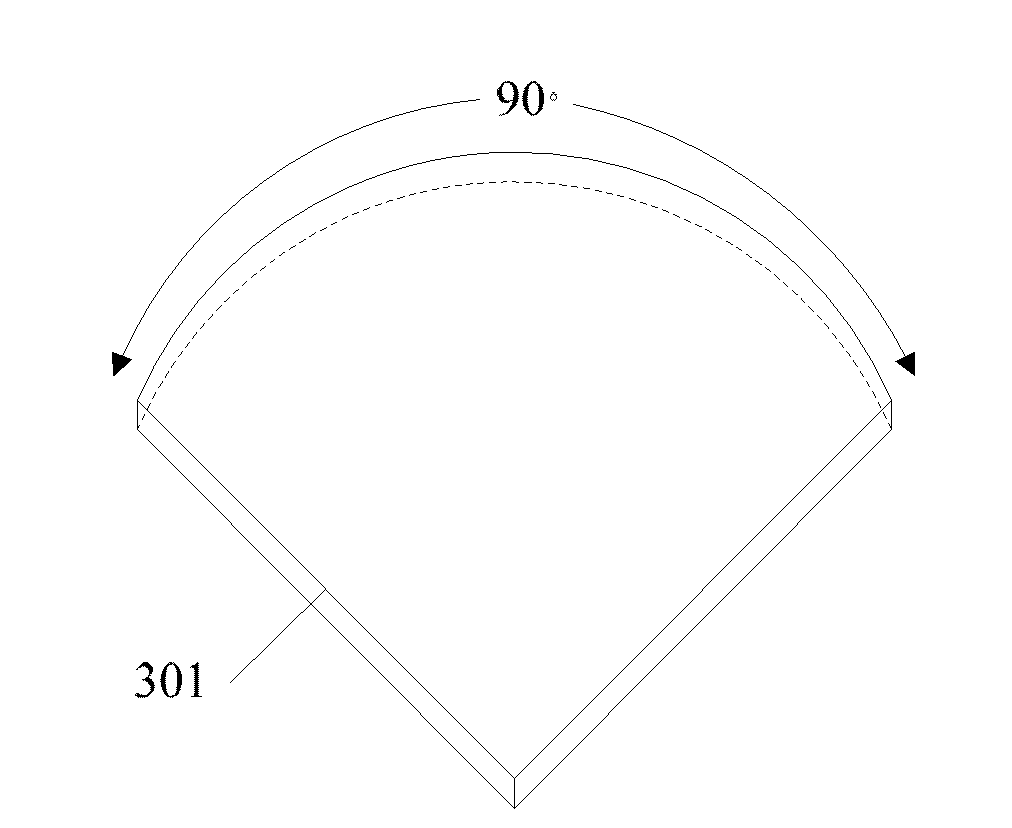

Solid-liquid mixed baffle plate type internal heat exchanger for space radiator

A hybrid, mixed flow technology, applied in direct contact heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve problems such as poor deposition and vibration resistance, large mass, and low heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In recent years, with the rapid development of large spacecraft and space stations, their power consumption will increase, which will inevitably lead to an increase in their thermal power consumption, making traditional thermal control technologies face new challenges and difficult to adapt to new development of. According to foreign literature, the existing space development plan chooses to use large-scale power supplies such as isotope power (its power supply is above 10kw), solar power (its power supply is above 100kw) and nuclear thermal power (its power supply is above 100kw). The system provides energy for large spacecraft. They are mainly intended to be used in IR monitoring spacecraft, space radar stations, space chemical laser platforms and space weapon platforms. Most of their power consumption is in the range of 10kw to 100kw. The Liberty space station consumes more power. The power consumption of the proposed first phase project is 100kw, and the power consu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com