Method for preparing vertical intermediate-frequency furnace by integrally casting and compounding furnace pipe and thermal insulation layer

An intermediate frequency furnace and vertical technology, which is applied in the field of carbonization, cemented carbide sintering vertical intermediate frequency furnace integral casting composite furnace and the preparation of insulation layer, can solve the problems of inconvenient maintenance and replacement, inability to meet the carbonization process, etc., and achieve convenient The effect of maintenance and replacement, cost saving and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

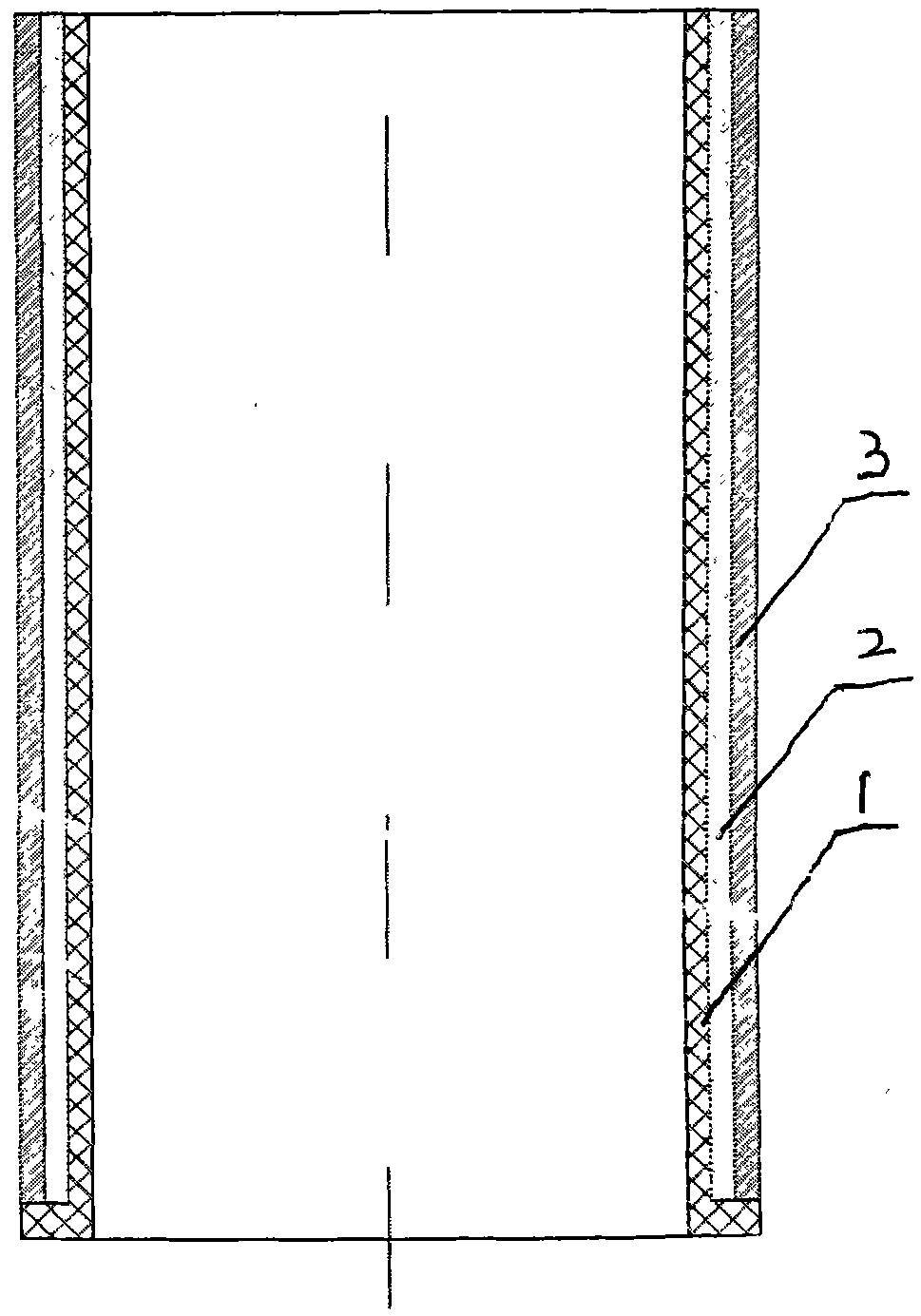

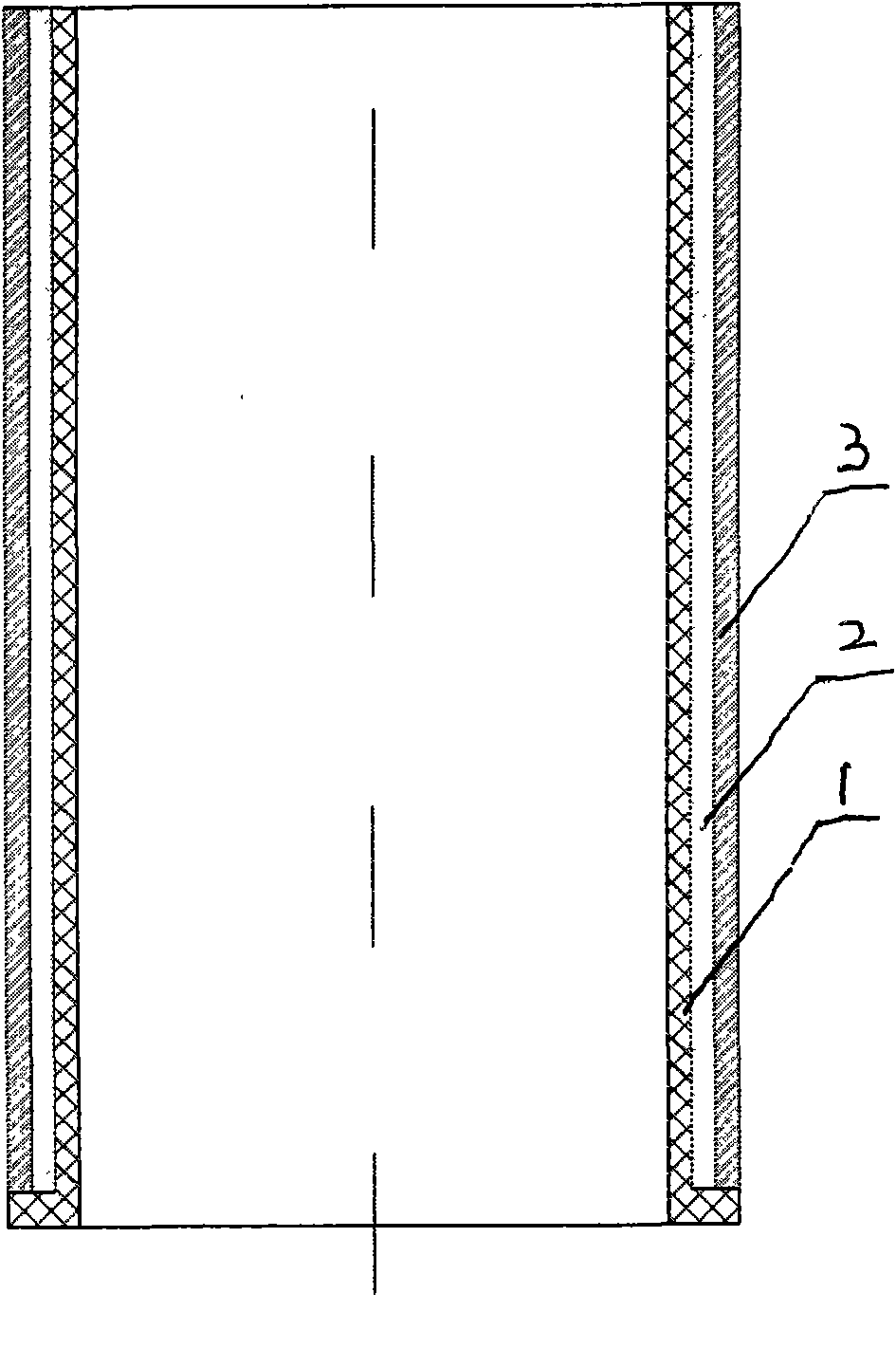

[0017] see figure 1 , the present invention is a carbonization, cemented carbide sintering vertical intermediate frequency furnace integral casting composite furnace and insulation layer preparation method, the refractory furnace with zirconia as aggregate and aluminum oxide hollow ball as aggregate, coarse corundum The thick corundum hollow sphere filler layer with hollow spheres as aggregate and the zirconia hollow sphere insulation layer with zirconia hollow spheres as aggregate are sequentially compounded and integrally cast, and the preparation method is as follows:

[0018] Step 1: Refractory furnace ingredients: in the refractory furnace with zirconia as aggregate and alumina hollow spheres as aggregate, the mass percentage of each component is: alumina hollow sphere 40%, a~ZrO 2 Micropowder 35%, add phosphoric acid or aluminum dihydrogen phosphate solution, binder is a~ZrO 2 30% of the mass percentage of fine powder, the corresponding density is 2.4~2.5g / cm 3 ;

[...

Embodiment 2

[0026] see figure 1 , the present invention is an integrally cast composite furnace and insulation layer in a vertical intermediate frequency furnace for carbonization and tungsten carbide sintering, a refractory furnace with zirconia as aggregate and alumina hollow ball as The coarse corundum hollow ball filler layer with the ball as the aggregate and the zirconia hollow ball insulation layer with the zirconia hollow ball as the aggregate are sequentially composited and integrally cast, and the preparation method is as follows:

[0027] Step 1: Refractory furnace ingredients: In the refractory furnace with zirconia as aggregate and alumina hollow spheres as aggregate, the mass percentages of each component are: alumina hollow spheres 65%, a~ZrO 2 Micropowder 55%, add phosphoric acid or aluminum phosphate solution, binder is a~ZrO 2 35% of the mass percentage of fine powder, the corresponding density is 2.4~2.5g / cm 3 ;

[0028] Step 2: Filling layer ingredients: In the rou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com