Cyclone gas-flotation separation device for treating oily sewage

A separation device, swirling air flotation technology, applied in flotation water/sewage treatment, grease/oily substance/float removal device, liquid separation, etc., to achieve the effect of easy installation and maintenance, high operation flexibility, and exquisite form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

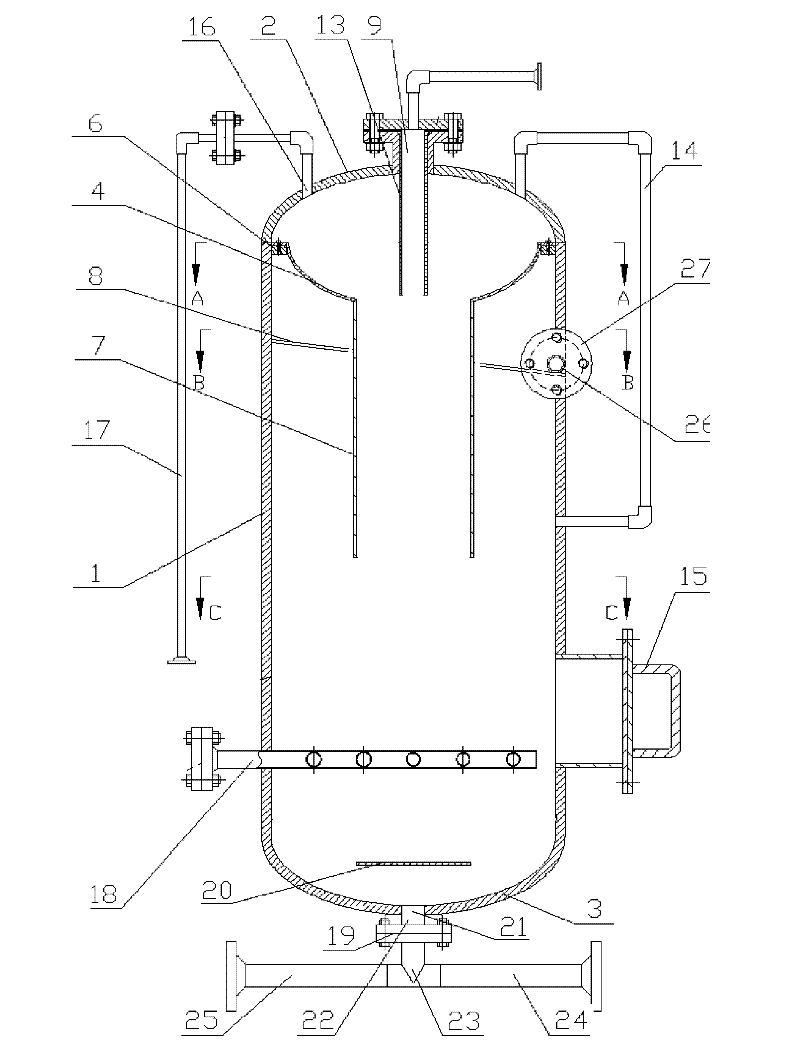

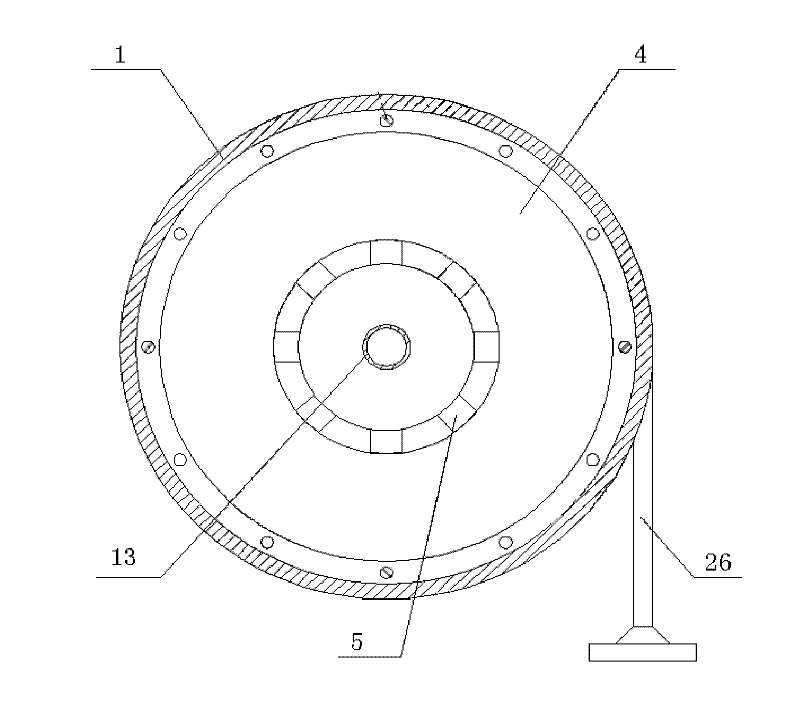

[0032] Embodiment 1, cyclone air flotation separation device for oily sewage treatment

[0033] The cyclone air flotation separation device for oily sewage treatment provided in this embodiment includes a cyclone air flotation combination mechanism and a gas-liquid mixing mechanism; Shaped upper head 2 and elliptical lower head 3; the ratio of the height of the swirling air flotation combination mechanism to the diameter of the cylinder 1 is 2.0; the inner wall of the cylinder 1 is connected with a spherical bowl-shaped oil collection cover with an open bottom 4. It is fixed on the lining plate 7 on the inner wall of the cylinder 1 by screws; the lower opening end of the oil collecting cover 4 is provided with a plurality of fan-shaped oil collecting ports 5 evenly arranged in the circumferential direction, which is convenient for collecting slick oil and foam floating The slag can also adapt to the sloshing of the liquid surface; the lower open end of the oil collection cover...

Embodiment 2

[0036] Embodiment 2, cyclone air flotation separation system for oily sewage treatment

[0037] The compact cyclone air flotation separation system for oily sewage treatment provided by the present invention can be combined in series or in parallel according to different requirements on treatment effect and working flow.

[0038] Figure 6 It is the structural representation of the cyclone air flotation separation system connected in series for oily sewage treatment. The oil discharged from the water port and the oil outlet is collected into the same pipeline, and the way of series connection can improve the separation effect of the compact cyclone air flotation separation system.

[0039] Figure 7 It is the structural representation of the cyclone air flotation separation system for oily sewage treatment connected in parallel, two cyclone air flotation separation devices 28 (i.e. the separation device in embodiment 1) carry out the purification treatment of oily sewage ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com