V-shaped turning tool and mounting tool post thereof

A turning tool and tool holder technology, which is applied to woodworking lathes, wood turning tools, wood drilling tools, etc., can solve problems such as unfavorable cutting, affecting processing accuracy, and elastic deformation of the tool handle, so as to achieve convenient sharpening and improve cutting. Dosage, effect of cutting edge sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are the specific embodiments of the V-shaped turning tool, further describing the technical solution of the present invention, but the present invention is not limited to these embodiments.

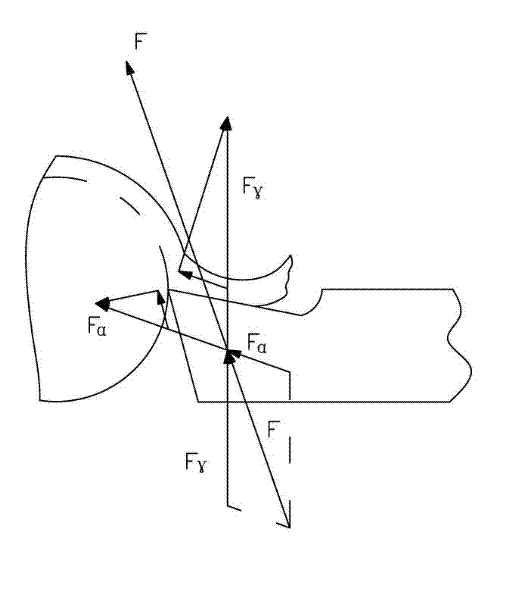

[0024] refer to Figure 2 to Figure 5 , in this embodiment, the V-shaped turning tool includes a handle 1, a V-shaped cutter head 2, and major and minor cutting edges 3 and 4 located on the cutter head 2, between the major and minor cutting edges 3 and 4 Intersect to form the tip 5, the main and minor cutting edges 3 and 4 are formed by the intersection of the front face 6 and the rear face 7, the minor front face 61 and the minor rear face 71 respectively, and the major and minor cutting edges 3 and 4 are located above the cutter head 2 , the handle 1 is connected with the bottom of the cutter head 2.

[0025] The relief angle and the auxiliary relief angle of the turning tool are 0° to 15°, and its preferred embodiment is 0°. Under this angle, the main and auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com