Slag-free surfacing welding rod

A surfacing welding electrode and welding core technology, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of poor electrical conductivity of the coating, low deposition rate, easy red tail, etc., to achieve small spatter, Reasonable crack distribution and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

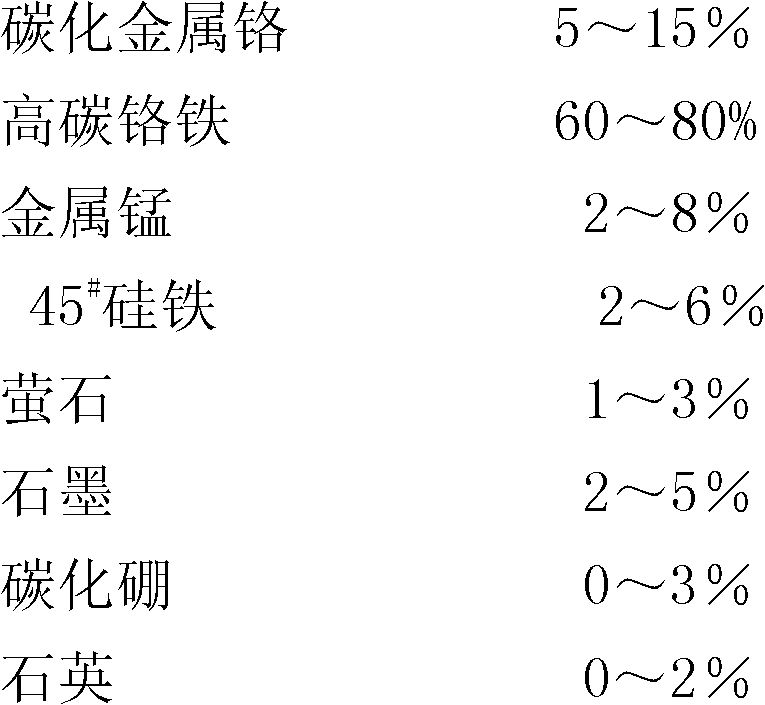

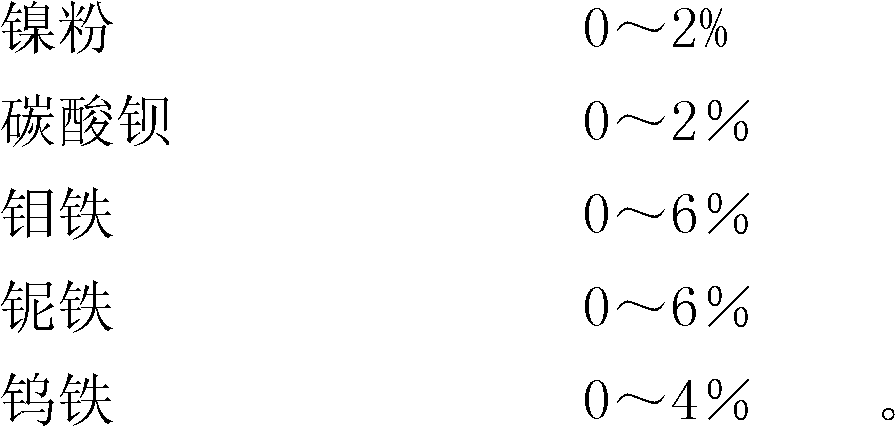

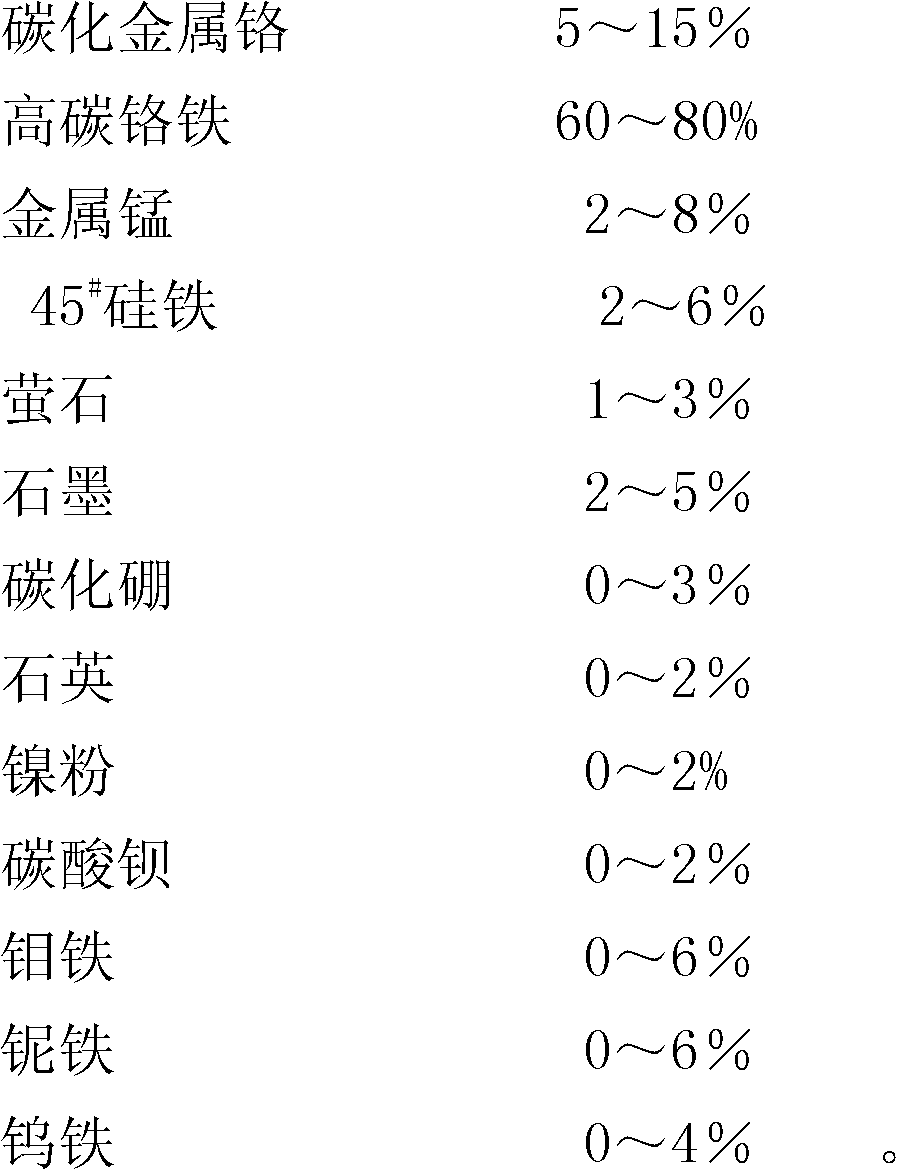

[0020] In terms of mass percentage, 15% of the powder raw material is chromium carbide, 61% of high-carbon ferrochrome, 5% of manganese metal, 3% of 45 # Ferrosilicon, 2% fluorite, 5% graphite, 3% boron carbide, 2% quartz sand, 1% barium carbonate, 1% nickel powder, 0.5% ferromolybdenum, 0.5% ferroniobium and 1% ferro-tungsten is mixed in the powder mixing equipment for 1 hour to obtain a powdery coating, wherein the content of C in the high-carbon ferrochrome is 7.5-8.5%, and the content of Cr is 60-65%. The content of Si is ≤3%, and the balance is Fe; the particle size of all the above-mentioned powders is -40 mesh.

[0021] Slowly add the potassium-sodium water glass whose weight is 5% of the weight of the drug skin powder into the prepared drug skin powder and stir evenly; adopt the H08A welding core, and the diameter of the welding core is 4.0mm; to add the modulus The mass ratio of the coating to the welding core after 45 potassium-sodium water glass is 2:1, and the coa...

Embodiment 2

[0023] In terms of mass percentage, the powder raw material is 5.5% of carbide metal chromium, 60% of high-carbon ferrochromium, 2% of metal manganese, 6% of 45 # Ferrosilicon, 3% fluorite, 4% graphite, 1% boron carbide, 0.5% quartz sand, 2% nickel powder, 6% ferromolybdenum, 6% ferroniobium and 4% ferrotungsten Mix in the powder mixing equipment for 1 hour to obtain a powdery coating, wherein the content of C in the high-carbon ferrochrome is 7.5-8.5%, the content of Cr is 60-65%, and the content of Si is ≤3 %, the balance is Fe; the particle size of all the above-mentioned powders is -40 mesh.

[0024] Slowly add the potassium-sodium water glass whose weight is that the modulus of 5% of the drug skin powder weight is 45 in the prepared drug skin powder, stir; adopt H08A welding core, welding core diameter 4.0mm; The mass ratio of the coating to the welding core is 2:1, and the coating is uniformly and centripetally pressed on the welding core to prepare a surfacing electrod...

Embodiment 3

[0026] In terms of mass percentage, the powder raw material is 5% of carbide metal chromium, 80% of high-carbon ferrochromium, 8% of metal manganese, 2% of 45 # Ferrosilicon, 1% fluorite, 2% graphite and 2% barium carbonate were mixed in the powder mixing equipment for 1 hour to obtain the powdered coating, wherein the C in the high-carbon ferrochrome The content of Cr is 7.5-8.5%, the content of Cr is 60-65%, the content of Si is ≤3%, and the balance is Fe; the particle size of all the above-mentioned powders is -40 mesh.

[0027] Slowly add the potassium-sodium water glass whose weight is that the modulus of 5% of the drug skin powder weight is 45 in the prepared drug skin powder, stir; adopt H08A welding core, welding core diameter 4.0mm; The mass ratio of the coating to the welding core is 2:1, and the coating is uniformly and centripetally pressed on the welding core to prepare a surfacing electrode. The surfacing layer (three layers) of the electrode adopts HRA-50 Rockw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com