Power module and power conversion device

A power module and conversion technology, applied in the field of power conversion devices, can solve the problems of deterioration of insulation performance, low cooling performance, no sealing of internal electronic components, etc., and achieve the effect of improving insulation reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

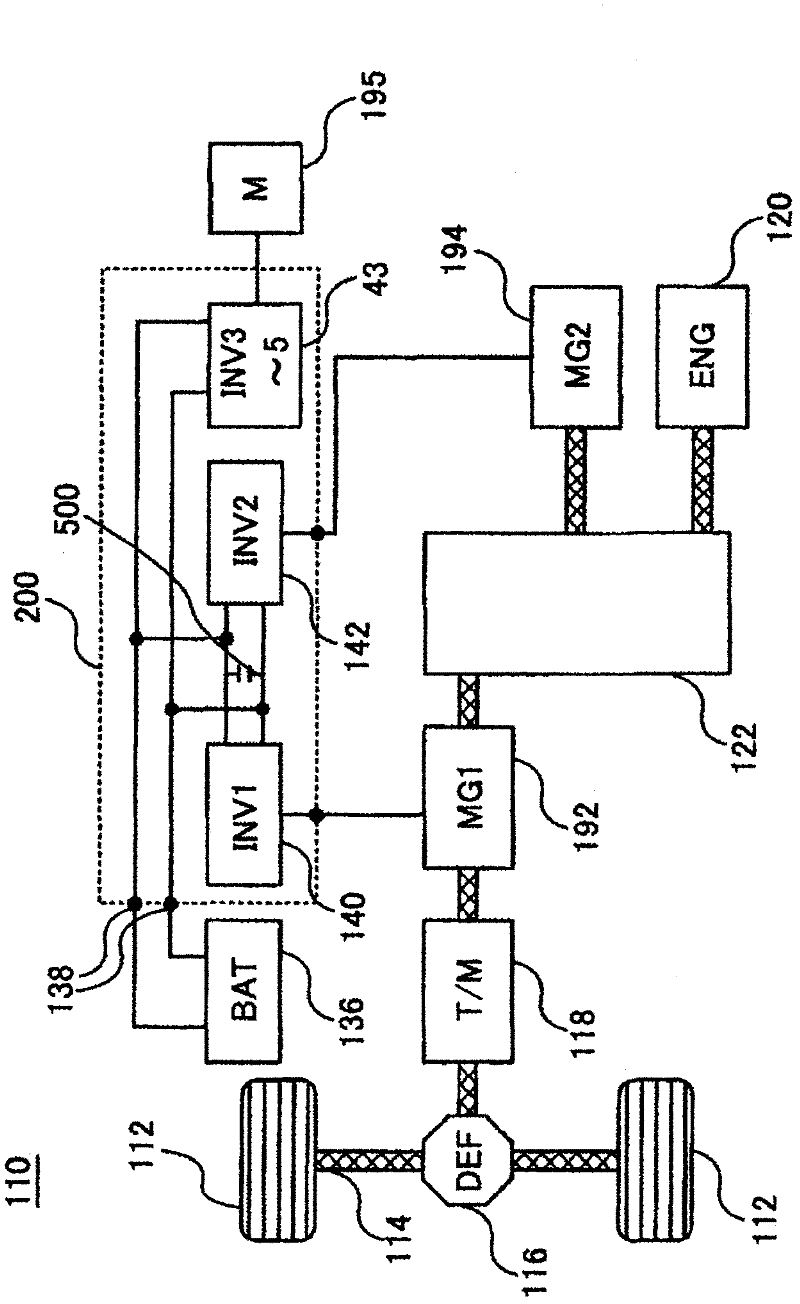

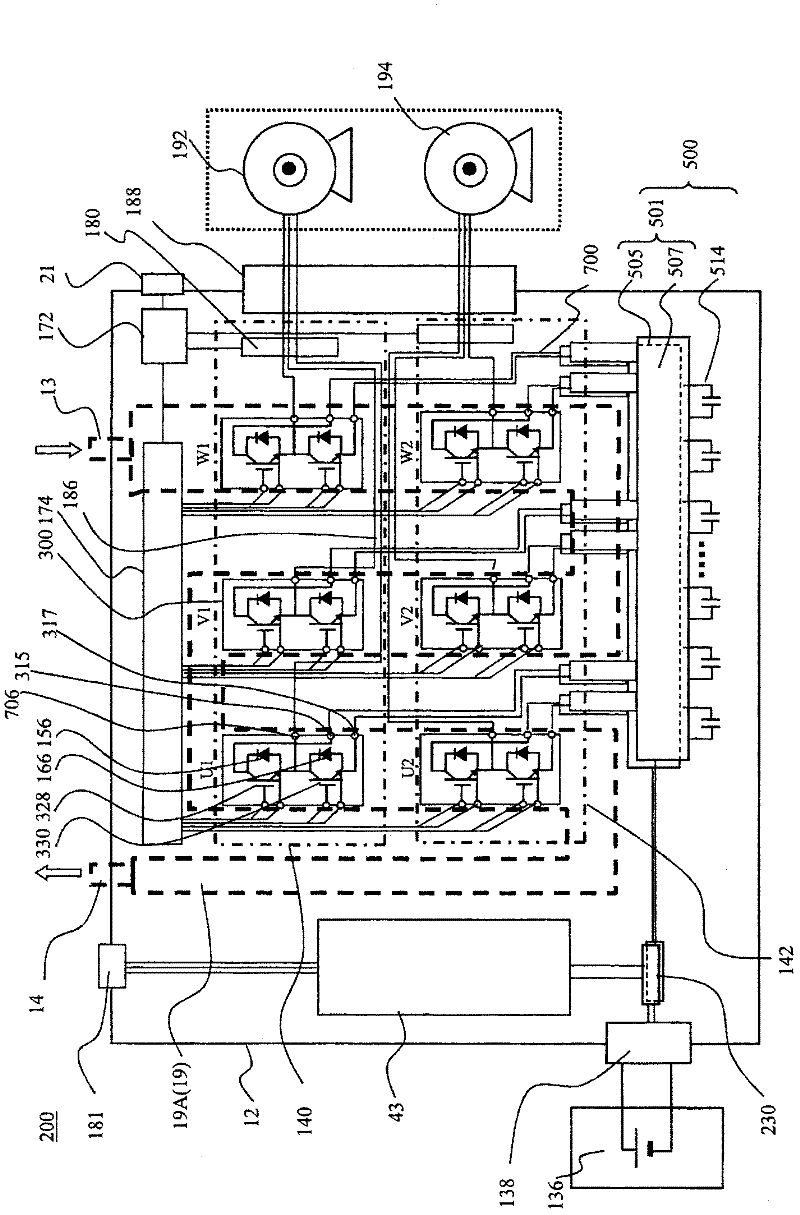

[0052] figure 1 is a diagram showing a control block of a hybrid vehicle. exist figure 1 Among them, a hybrid electric vehicle (hereinafter referred to as "HEV") 110 is one electric vehicle and includes two vehicle driving systems. One of the drive systems is an engine system that uses an engine 120 as an internal combustion engine as a power source. The engine system is mainly used as a driving source of HEV 110 . Another driving system is an on-vehicle motor system using motor generators MG1 192 and MG2 194 as power sources. The on-vehicle motor system is mainly used as a drive source of HEV 110 and a power generation source of HEV 110 . The motor generators MG1 192 and MG2 194 are, for example, synchronous machines or induction machines, and operate as electric motors or generators depending on the method of operation, so they are referred to as motor generators here.

[0053] The front wheel axle 114 is rotatably supported at the front of the vehicle body. A pair of ...

Embodiment 2

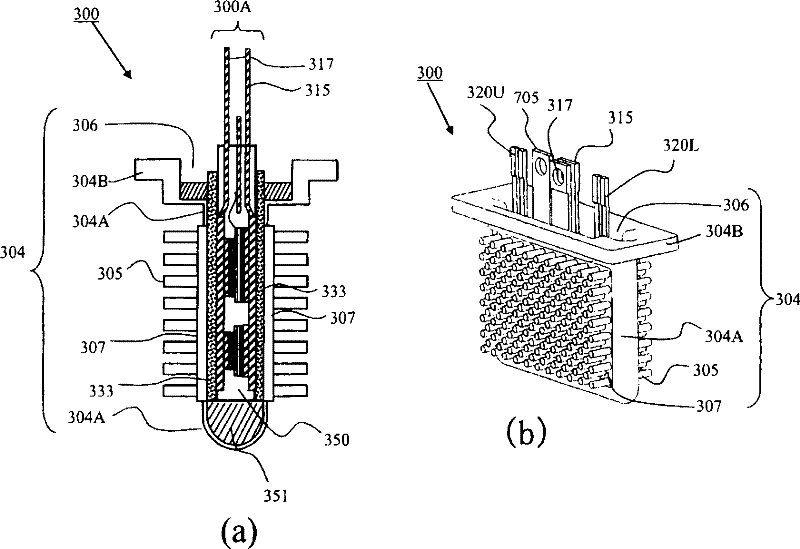

[0139] Figure 11 (a) is a cross-sectional view of a power module 300 according to another embodiment, Figure 11 (b) is an exploded cross-sectional view of a power module 300 according to another embodiment. Hereinafter, parts different from those of the first embodiment will be described, and the configurations assigned the same symbols as those of the first embodiment have the same functions.

[0140] In this embodiment, an aluminum insulating plate 340 is disposed instead of the insulating sheet 333 according to the first embodiment. Adhesive thin resin insulating layers 342 are formed on both main surfaces of the aluminum insulating plate 340 . The alumina plate 341 is sandwiched between two resin insulating layers 342, and the whole is treated with alumina to form alumina layers 601 on the front and back surfaces. The alumina plate 341 and the two resin insulating layers 342 are bonded by thermocompression.

[0141] The module primary sealing body 300A is firmly bond...

Embodiment 3

[0149] Figure 16 (a) is a cross-sectional view of a power module 300 according to another embodiment, Figure 16 (b) is a sectional view at the time of assembly of the power module 300 according to another embodiment. Hereinafter, parts different from those of the first embodiment will be described, and the configurations assigned the same symbols as those of the first embodiment have the same functions.

[0150] In this embodiment, flow path forming bodies 380A and 380B in which a flow path 381 is formed inside are used instead of the can cooler 304 according to the first and second examples. Such as Figure 16 As shown in (b), the alumina treatment described in Example 1 was performed on the surfaces 382A and 382B of the flow channel forming bodies 380A and 380B that are in contact with the insulating sheet 333 .

[0151] Accordingly, it is not necessary to form the organic acid-based alumina layer 601B on the inner flat surface 308 of the can cooler 304 as shown in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com