Manufacture method of through hole of large size

A manufacturing method and large-scale technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as difficulty in achieving a sufficient thickness of the barrier layer, and achieve the effect of a simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

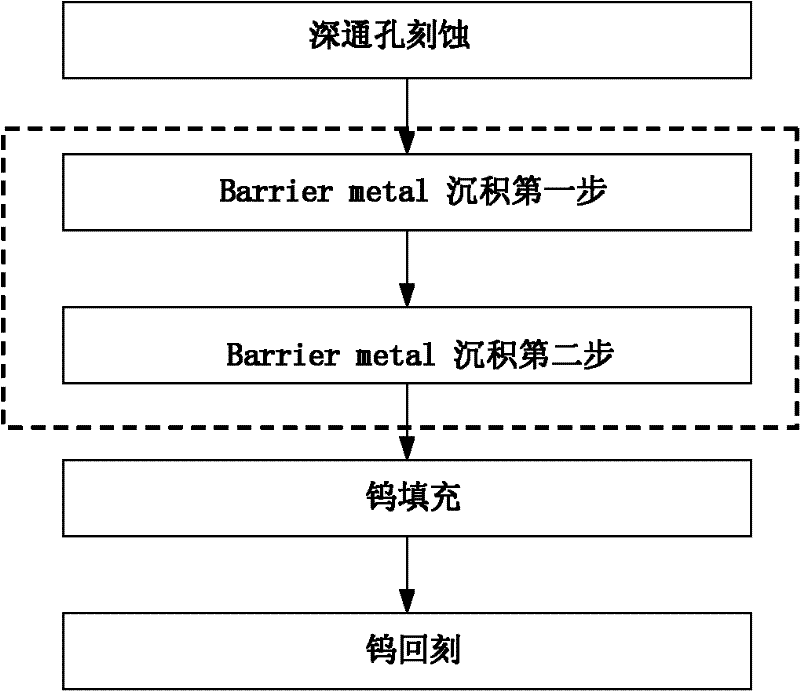

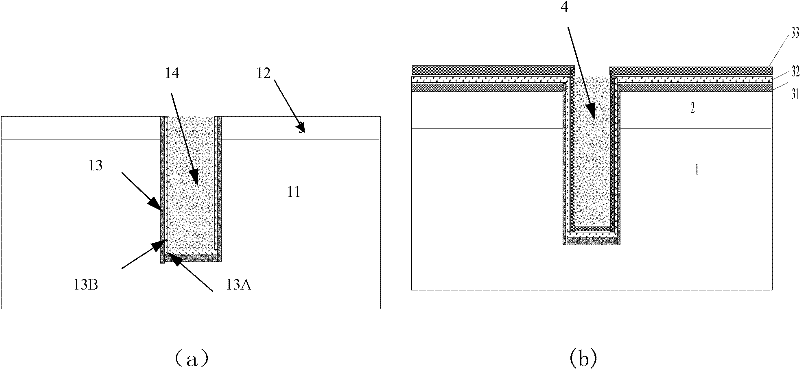

[0024] The invention provides a novel method for making large-sized through holes. After the through holes are etched, two different processes are used to deposit the barrier layer metal. First, MOCVD (Metal Organic Chemical Vapor Deposition) is used to deposit metal with good steps. The Ti / TiN film with covering ability can block the erosion (attack) on the side wall and bottom of the hole during the tungsten deposition process, and then use PVD (physical vapor deposition) method to deposit a certain thickness of TiN as the silicon surface for subsequent tungsten back etching barrier layer. In this way, both the electrical performance of the deep hole and the corresponding process control can be taken into account.

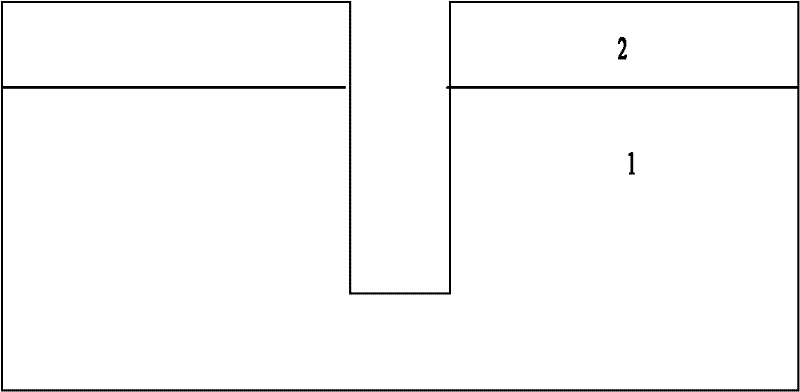

[0025] The manufacturing method of a kind of novel large-size through-hole of the present invention, its specific technologica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com