Steel tube concrete frame inbuilt steel plate core cylinder with soft steel sleeves at bottom and producing method of steel tube concrete frame inbuilt steel plate core cylinder

A technology of concrete filled steel tube and steel plate concrete, which is applied to building components, earthquake resistance, construction, etc., can solve the problems of insufficient seismic performance and structural measures, and insufficient seismic energy dissipation capacity of internal materials to achieve good post-seismic performance. , Improve the overall seismic capacity, improve the effect of seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

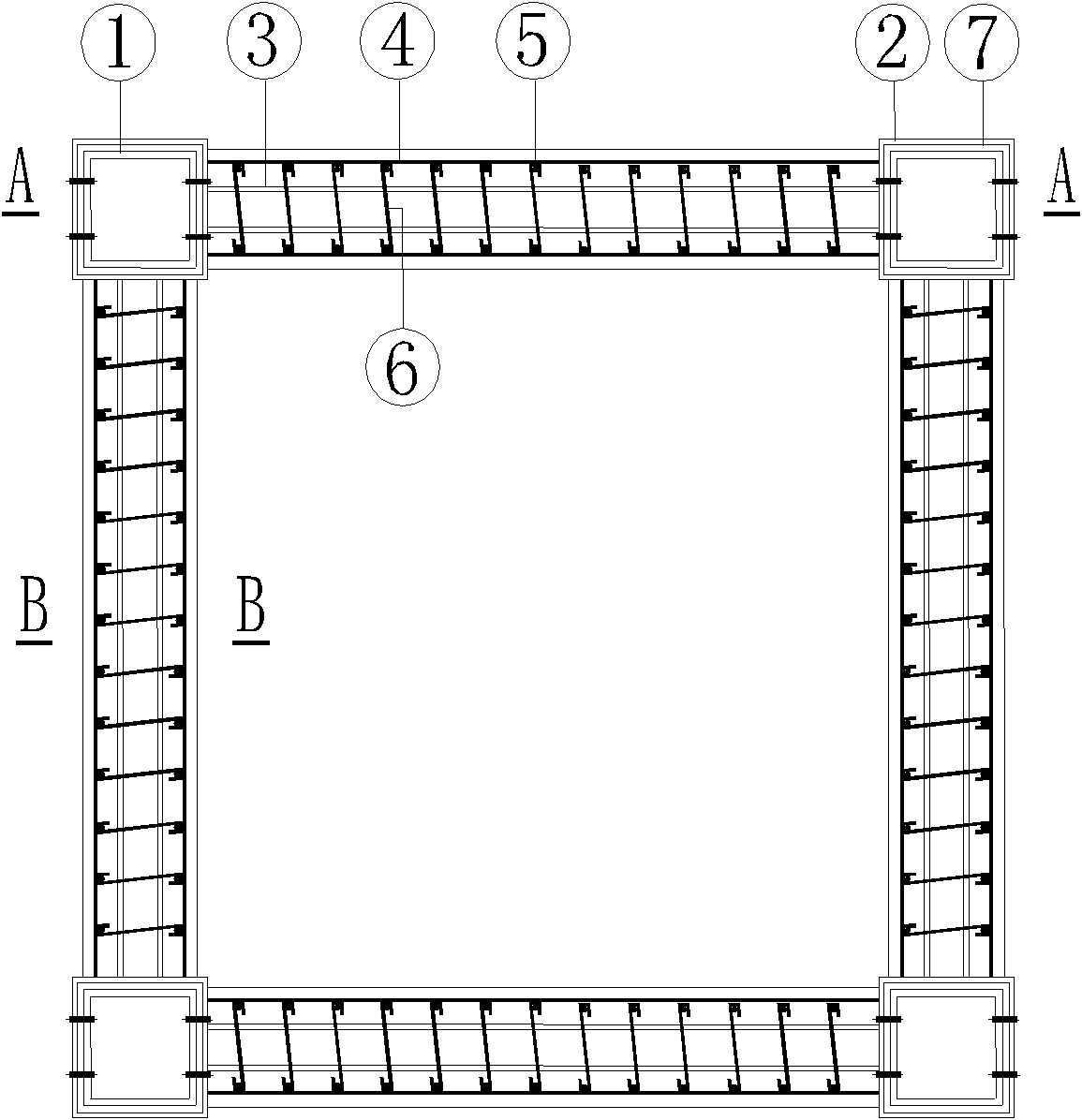

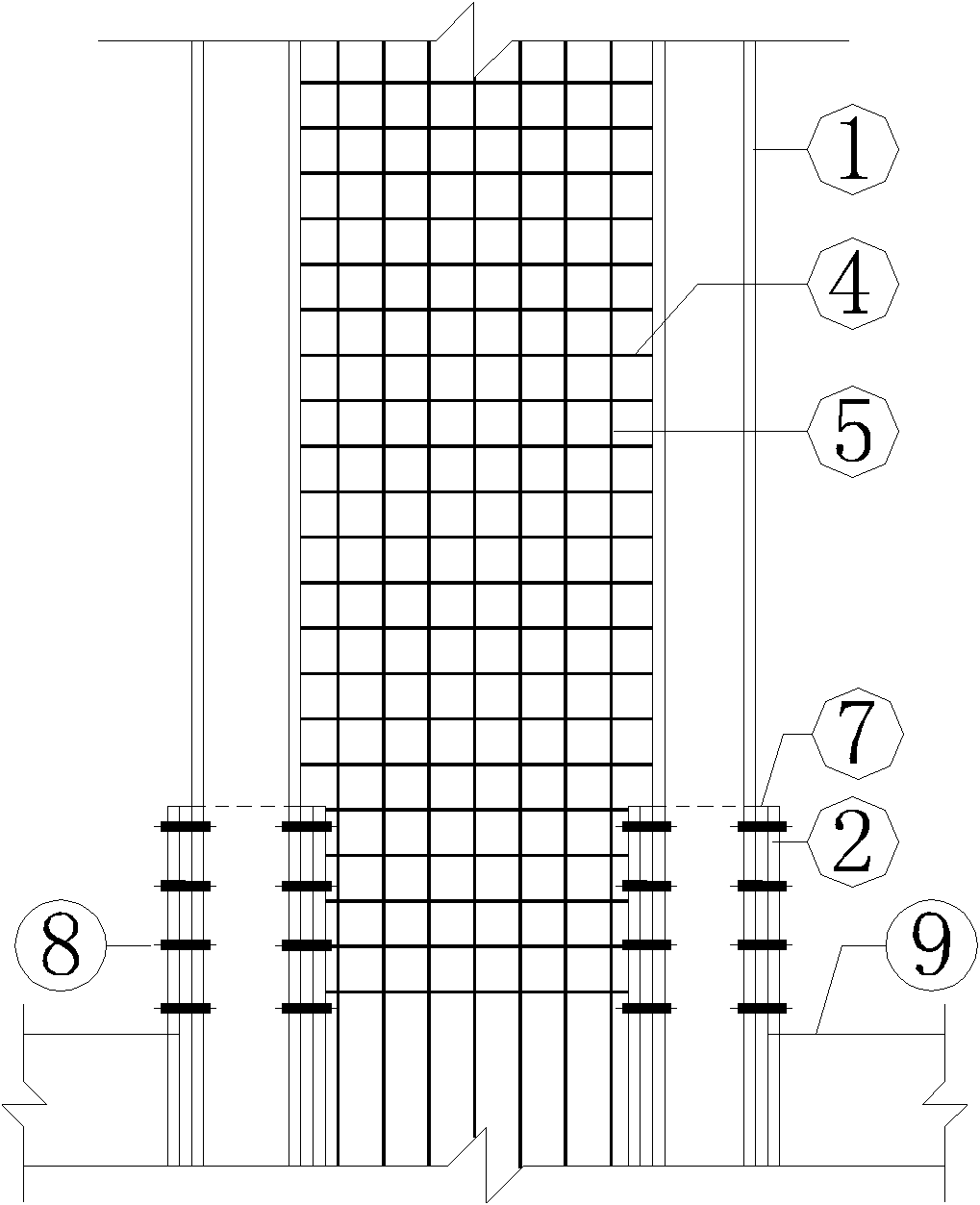

[0040] The bottom has a mild steel casing and a steel plate core tube is built in the steel tube concrete frame, such as figure 1 , image 3 , Figure 4 and Figure 5As shown, the frame column of the core tube is a rectangular cross-section embedded high-toughness composite steel tube concrete column. It is composed of surrounding steel pipe concrete frame columns and steel plate concrete shear walls; the steel plate concrete shear walls are provided with shear wall steel plates 3, and the steel plate concrete shear walls on both sides of the shear wall steel plates 3 are equipped with Reinforcement mesh composed of transversely distributed steel bars 4 and longitudinally distributed steel bars 5 is connected between the steel meshes with tensioned steel bars 6; the steel pipe concrete frame columns are set at both ends of the steel plate concrete shear walls, that is, the surrounding steel plate concrete shear walls intersect The steel pipe concrete frame column is compose...

Embodiment 2

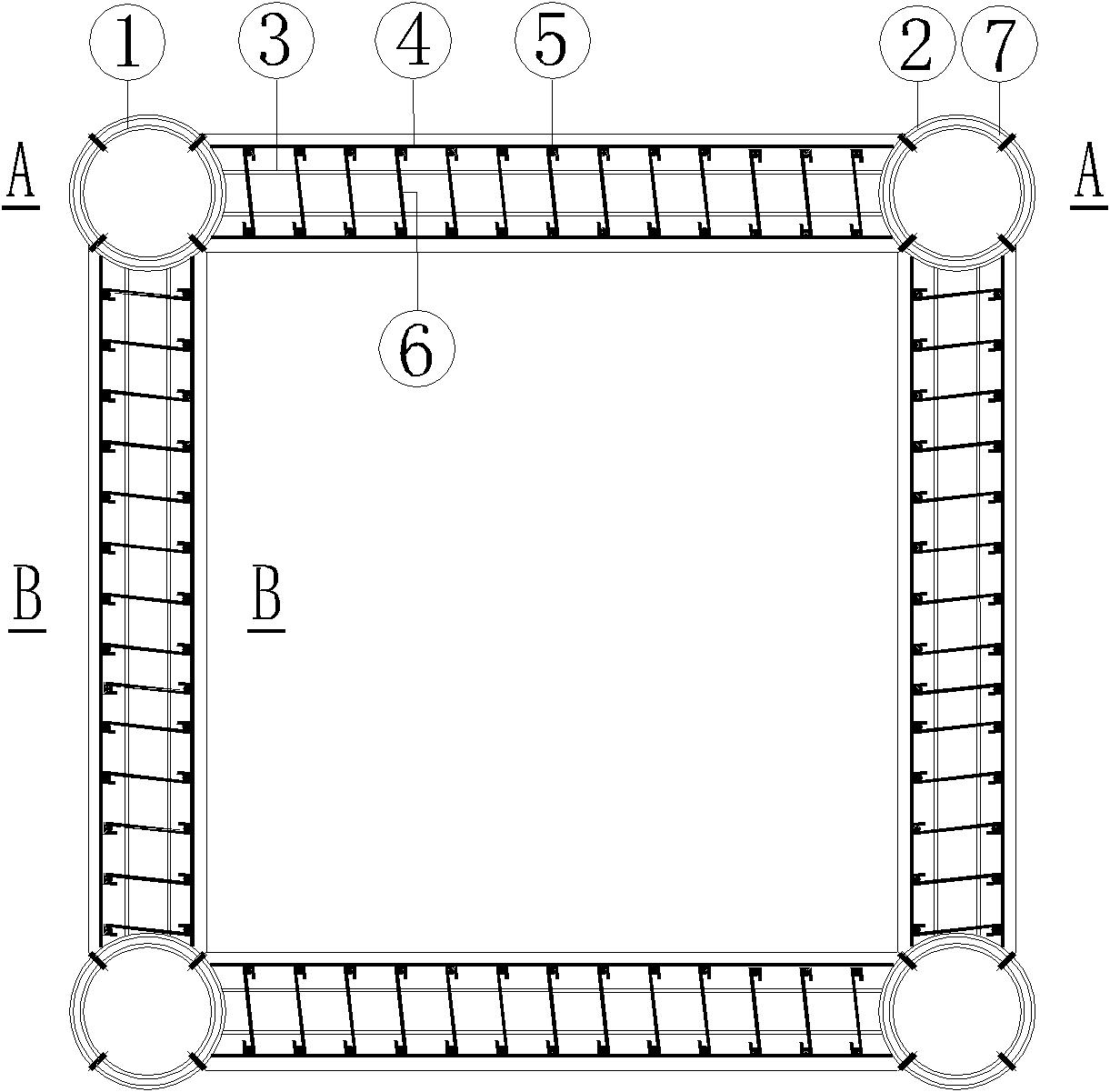

[0050] Such as figure 2 As shown, the frame column of the core tube is a circular cross-section embedded high-toughness composite steel tube concrete column, and its section is shown in image 3 and Figure 4 As shown, the detailed structure is as Figure 6 shown. Other construction measures and construction method are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com