Cross cool easy cation-dyeable polyester (ECDP) fiber and production method thereof

A polyester fiber and cationic technology, which is applied to the cross-shaped atmospheric pressure cationic dyeable ice-cool polyester fiber and its manufacturing field, can solve the problems of difficulty in dyeing cool fibers and high dyeing cost, and achieves bright color, high color fastness, Good comfort and health benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

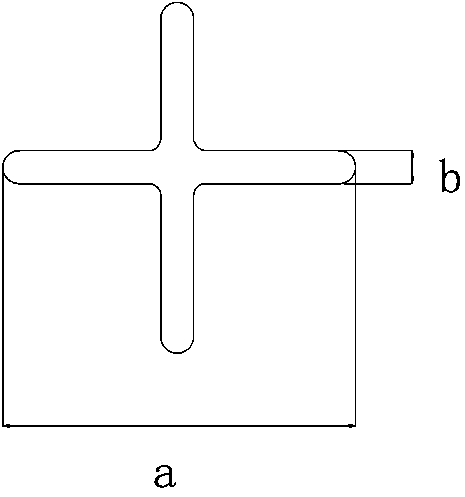

[0025] Embodiment 1: the cross-shaped atmospheric pressure cationic dyeable ice-cool polyester fiber of this example, the cross-section of the fiber is cross-shaped, and the content of its mica powder is 0.8%, and the rest is normal pressure cationic dyeable polyester, the monofilament of the fiber The fineness is 1.33dtex.

[0026] The preparation method is as follows: firstly mix mica powder and ECDP at a mass ratio of 20:80, and then granulate through a twin-screw extruder to prepare cold masterbatch.

[0027] Then dry cold masterbatch and ECDP are melt-blended and spun with a mass ratio of 4:96, and sprayed out through a cross-shaped spinneret, wherein such as figure 1 , the spinneret hole length a is 0.6mm, the blade width b is 0.10mm, and then cooled by blowing, stretched, shaped, cut and packaged to form a cross-shaped atmospheric pressure cationic dyeable cold polyester fiber. Its main process parameters are as follows: spinning temperature is 278~290°C, cooling blowi...

Embodiment 2

[0028] Embodiment 2: The cross-shaped atmospheric pressure cationic dyeable ice-cold polyester fiber of this example, the cross section of the fiber is cross-shaped, the content of its mica powder is 1.0%, the rest is normal pressure cationic dyeable polyester, the monofilament of the fiber The fineness is 1.33dtex.

[0029] The preparation method is as follows: firstly mix mica powder and ECDP at a mass ratio of 20:80, and then granulate through a twin-screw extruder to prepare cold masterbatch.

[0030] Then dry cold masterbatch and ECDP are melt-blended and spun with a mass ratio of 5:95, and sprayed out through a cross-shaped spinneret, wherein such as figure 1 , The length a of the spinneret hole is 0.6mm, and the leaf width b is 0.10mm, and then air-cooled, stretched, shaped, cut and packaged to form a cross-shaped normal-pressure cationic dyeable cold polyester fiber. The main process parameters are as follows: spinning temperature is 278~290°C, cooling blowing wind sp...

Embodiment 3

[0031] Embodiment 3: the cross-shaped atmospheric pressure cationic dyeable cold polyester fiber of this example, the cross-section of the fiber is cross-shaped, and the content of its mica powder is 1.5%, and the rest is normal pressure cationic dyeable polyester, the monofilament of the fiber The fineness is 1.33dtex.

[0032] The preparation method is as follows: firstly, mica powder and ECDP sheet are mixed at a mass ratio of 15:85, and then granulated by a twin-screw extruder to prepare cold masterbatch.

[0033] Then dry cold masterbatch and ECDP are melt-blended and spun with a mass ratio of 10:90, and sprayed out through a cross-shaped spinneret, wherein such as figure 1 , the spinneret hole length a is 0.6mm, the blade width b is 0.10mm, and then cooled by blowing, stretched, shaped, cut and packaged to form a cross-shaped atmospheric pressure cationic dyeable cold polyester fiber. Its main process parameters are as follows: spinning temperature is 278~290°C, cooling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com