Sintering combustion improver and adding device and adding method thereof

A combustion aid and fuel technology, applied in the field of enhanced combustion aid and its adding device, can solve the problems affecting the basicity stability rate and grade stability rate of sinter, the fluctuation of chemical composition of sinter, and the poor strength of sinter, etc., to achieve effective Conducive to solid fuel, improvement of metallurgical performance indicators, improvement of consolidation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Sintering combustion aid preparation. Its composition is mainly composed of elemental substances and inorganic compounds. The simple substance is rare earth element, the inorganic compound is potassium permanganate, boric acid, magnesium chloride, ferrous oxide, nitrate, manganese dioxide and quicklime, and the raw material is powder.

[0021] By weight percentage, extract 1.3% of rare earth, 22% of potassium permanganate, 10% of boric acid, 7% of magnesium chloride, 25% of ferrous oxide, 11% of nitrate, 15% of manganese dioxide and 8.7% of quicklime powder, after mixing Put it into a mixer and stir well to make the sintering combustion aid of the present invention.

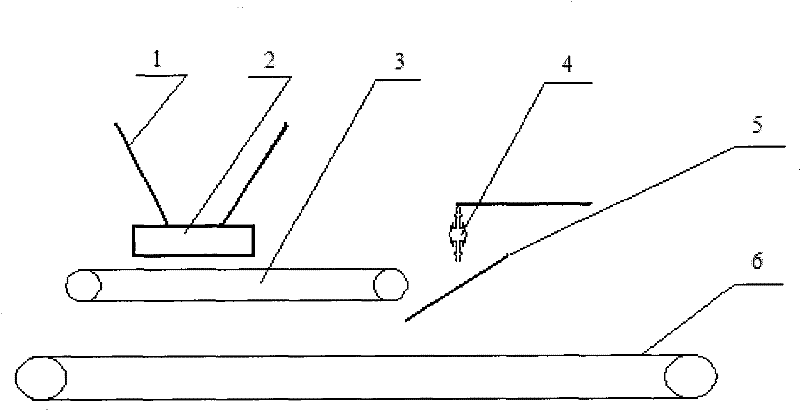

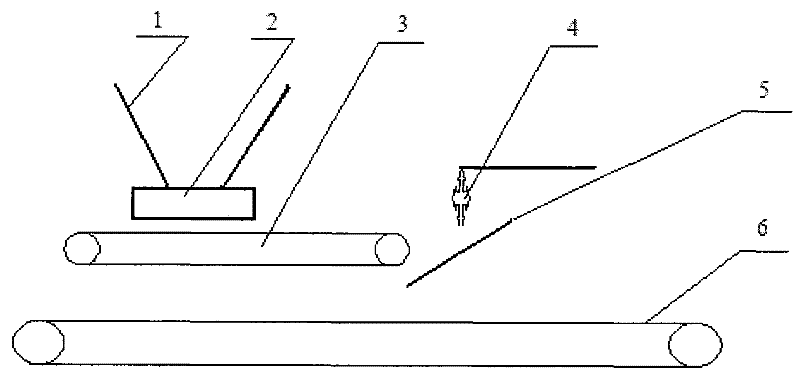

[0022] The sintering combustion aid is added to the device for preparation. The sintering combustion aid adding device is composed of a mine tank 1, a disc feeder 2, a belt electronic scale 3, a water adding nozzle 4 and a feeding plate 5. A "V" shaped ore tank 1 with a large upper opening and a small l...

Embodiment 2

[0025] By weight percentage, extract 1.0% of rare earth, 25% of potassium permanganate, 8% of boric acid, 5% of magnesium chloride, 20% of ferrous oxide, 20% of nitrate, 11% of manganese dioxide and 10% of quicklime powder, after mixing Put it into a mixer and stir well to make the sintering combustion aid of the present invention.

[0026] The composition and preparation method of the sintering combustion aid adding device are the same as in Example 1, except that the angle between the receiving plate 5 and the horizontal plane is 60°.

[0027] The steps of adding the sintering combustion aid are the same as in Example 1, but the ratio of combustion aid to fuel is 0.6:100.

Embodiment 3

[0029] By weight percentage, extract 0.7% of rare earth, 27% of potassium permanganate, 6% of boric acid, 3% of magnesium chloride, 15% of ferrous oxide, 27.3% of nitrate, 8% of manganese dioxide and 13% of quicklime powder, after mixing Put it into a mixer and stir well to make the sintering combustion aid of the present invention.

[0030] The composition and preparation method of the sintering combustion aid adding device are as in Example 1, and the angle between the feeding plate 5 and the horizontal plane is 40°.

[0031] The steps of adding the combustion aid for sintering are as in Example 1, and the ratio of the combustion aid to fuel is 0.8:100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com