Sandblast-free corrosion-proof composite coating for thermal spraying and preparation process thereof

A technology of composite coating and thermal spraying coating, which is applied in the direction of metal material coating process, anti-corrosion coating, coating, etc., to achieve the effect of simplifying the construction process, reducing construction cost and improving the scope of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

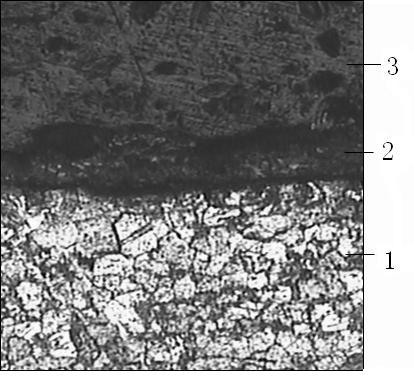

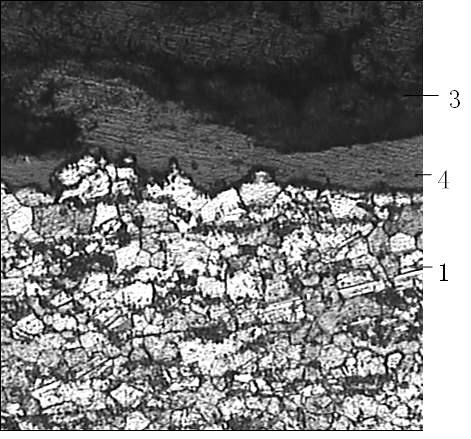

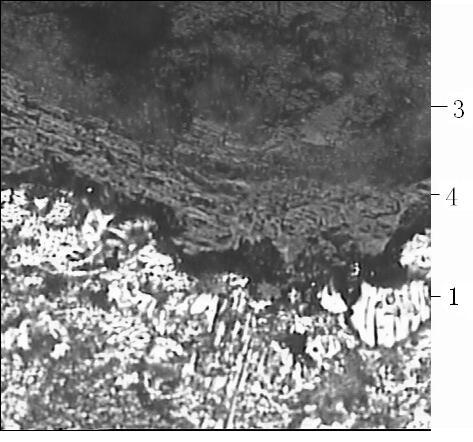

Image

Examples

Embodiment 1

[0057] A sandblasting-free anticorrosion composite coating for thermal spraying, comprising a rust primer and a sandblasting-free roughening layer,

[0058] The rusty primer is obtained by mixing and coating the rusty primer A component and the rusty primer B component,

[0059] The first component of rust primer is composed of the following components:

[0060] Modified epoxy resin 30%,

[0061] Medium oil semi-drying alkyd resin 20%;

[0062] 30% of highly imidized butylated melamine resin with a degree of etherification of 4,

[0063] Solvent 20%,

[0064] The modified epoxy resin is composed of the following components: 43.00% bisphenol A liquid epoxy resin with a molecular weight of 500-600, 25.00% butanol, 14.00% propylene glycol methyl ether acetate, and 18.00% phosphoric acid;

[0065] Solvent is the mixture of xylene and n-butanol weight ratio 1: 1;

[0066] Component B of the rust primer is composed of phosphoric acid and potassium ferrocyanide in a mass ratio o...

Embodiment 2

[0082] A sandblasting-free anticorrosion composite coating for thermal spraying, comprising a rust-carrying primer, a sandblasting-free roughening layer, a thermal spraying layer, a sealing primer and a topcoat.

[0083] The rusty primer is obtained by mixing and coating the rusty primer A component and the rusty primer B component,

[0084] The first component of rust primer is composed of the following components:

[0085] Modified epoxy resin 40%,

[0086] Medium oil semi-drying alkyd resin 10%;

[0087] 20% of highly imidized butylated melamine resin with a degree of etherification of 4,

[0088] Solvent 30%,

[0089] The modified epoxy resin is composed of the following components: 43.00% bisphenol A liquid epoxy resin with a molecular weight of 500-600, 25.00% butanol, 14.00% propylene glycol methyl ether acetate, and 18.00% phosphoric acid;

[0090] Solvent is the mixture of xylene and n-butanol weight ratio 1: 1;

[0091] Component B of the rust primer is composed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com