High-emission transparent heat-insulating paint in atmospheric window regions and preparation method thereof

A technology of atmospheric windows and thermal insulation coatings, applied in the field of coatings, can solve the problems of low emissivity in the atmospheric window area and inability to effectively dissipate heat, and achieve effective heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

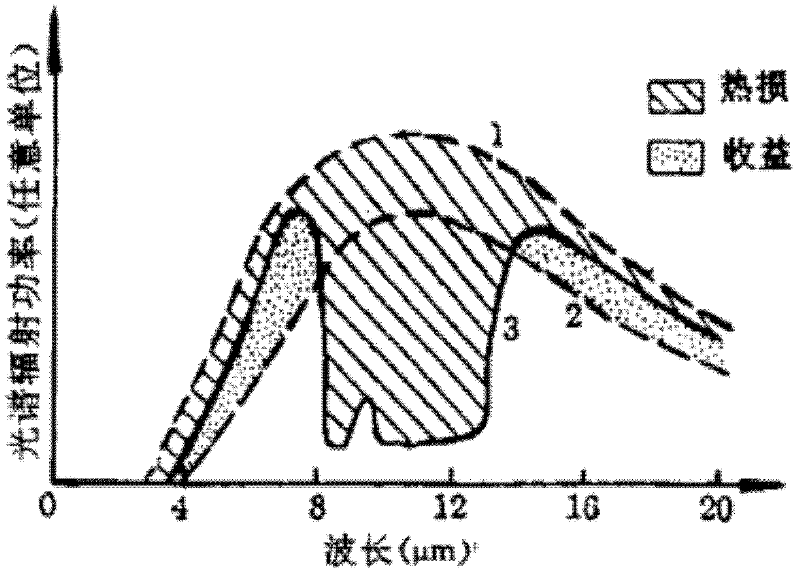

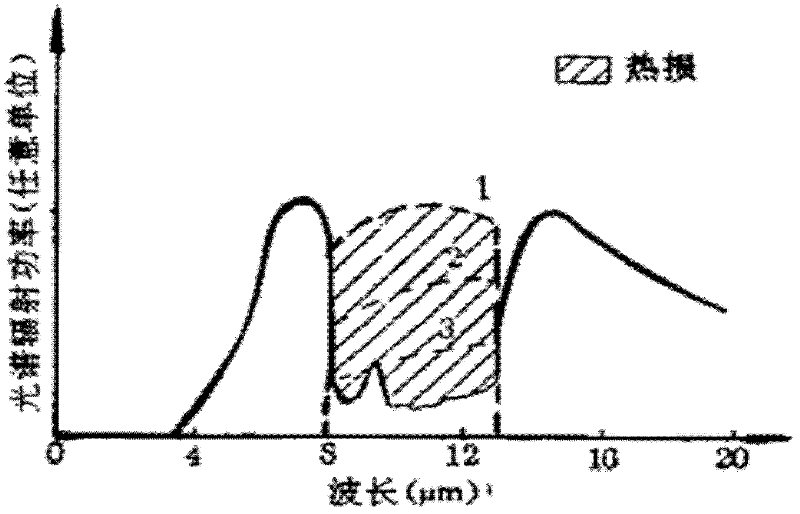

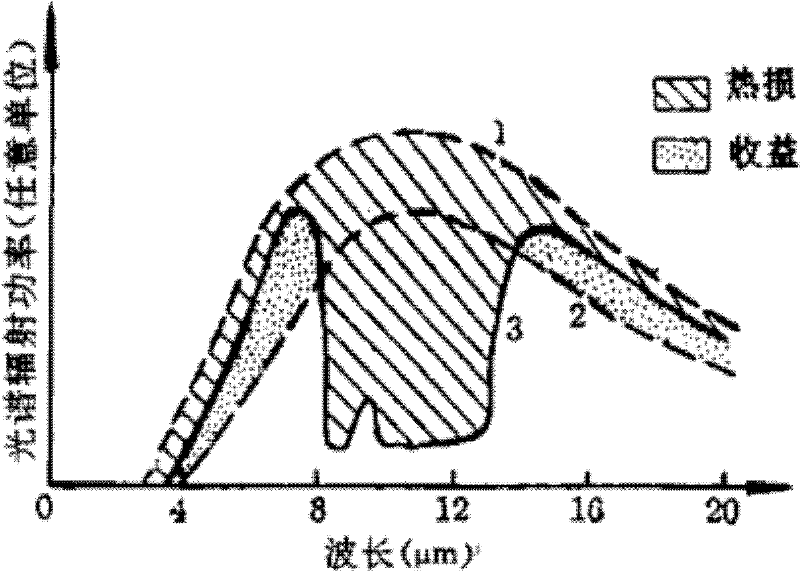

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, a transparent heat-insulating coating with high emission in the atmospheric window area, by weight, the main material of the transparent heat-insulating coating is composed of the following components: 50 parts of polyacrylate emulsion, nanometer antimony-doped tin dioxide (particle diameter 5-60nm) 15 parts, nano-mullite powder (particle size 5-60nm) 15 parts, 2 parts of sodium hexametaphosphate as an anionic dispersant, 4 parts of DP270 dispersant as a non-ionic dispersant , 1 part of 090 defoamer, 3 parts of hydroxyethyl cellulose ether as a thickener, 1 part of polypropylene oxide as a leveling agent, 1 part of alcohol ester-12 as a film-forming aid, as an antifreeze 1 part of propylene glycol, 7 parts of distilled water.

[0037] Its preparation method is to carry out following steps successively:

[0038] 1), Premix:

[0039] Add 7 parts of distilled water, 2 parts of sodium hexametaphosphate, 4 parts of DP270 dispersant and 0.3 part of 090 defoame...

Embodiment 2

[0044] Embodiment 2, a transparent heat-insulating coating with high emission in the atmospheric window, by weight, the main material of the transparent heat-insulating coating is made up of the following components: 50 parts of styrene-acrylic emulsion, fluorine-doped tin dioxide (particle diameter is 5~ 60nm) 15 parts, nano mullite powder (particle size 5 ~ 60nm) 15 parts, sodium hexametaphosphate as an anionic dispersant 2.5 parts, DP270 dispersant as a nonionic dispersant 5 parts, 090 1 part of foaming agent, 3 parts of hydroxyethyl cellulose ether as a thickener, 1 part of polypropylene oxide as a leveling agent, 1 part of alcohol ester-12 as a film-forming aid, 1 part of propylene glycol as an antifreeze parts, 6 parts of distilled water.

[0045] Its preparation method is to carry out following steps successively:

[0046] 1), Premix:

[0047] Add 6 parts of distilled water, 2.5 parts of sodium hexametaphosphate, 5 parts of DP270 dispersant and 0.3 part of 090 defoame...

Embodiment 3

[0052] Embodiment 3, a transparent heat-insulating coating with high emission in the atmospheric window, by weight, the main material of the transparent heat-insulating coating is composed of the following components: 50 parts of styrene-acrylic emulsion, nano-indium tin oxide (particle diameter is 5-60nm ) 7 parts, 8 parts of nano-antimony-doped tin dioxide (with a particle size of 5-60nm), 15 parts of nano-mullite powder (with a particle size of 5-60nm), 2.5 parts of sodium hexametaphosphate as an anionic dispersant , 5 parts of DP270 dispersant as a non-ionic dispersant, 1 part of 090 defoamer, 3 parts of hydroxyethyl cellulose ether as a thickener, 0.5 parts of polypropylene oxide as a leveling agent, as a film-forming agent 1 part of alcohol ester-12 as auxiliary agent, 1 part of propylene glycol as antifreeze, and 6 parts of distilled water.

[0053] Its preparation method is to carry out following steps successively:

[0054] 1), Premix:

[0055] Add 6 parts of distil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com