Quaternary ammonium type cationic starch gene controlled release vector material and preparation method and application thereof

A technology of cationic starch and controlled release carrier, applied in the field of natural polymer materials in medicine, can solve the problems of degradation, unsolved gene transfection efficiency, inability to escape the recognition and clearance of the reticuloendothelial system, etc., and achieves good biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

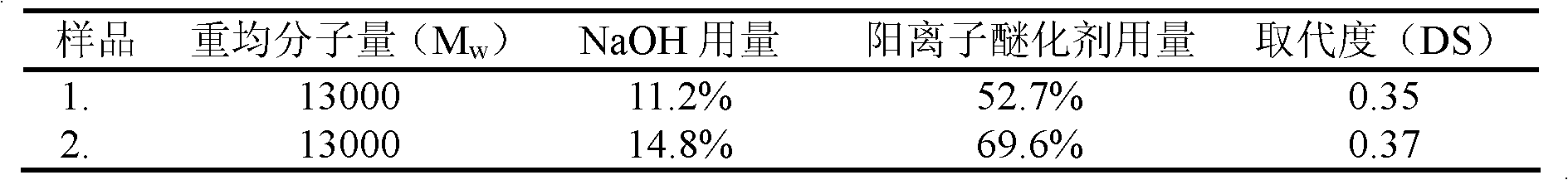

Embodiment 1

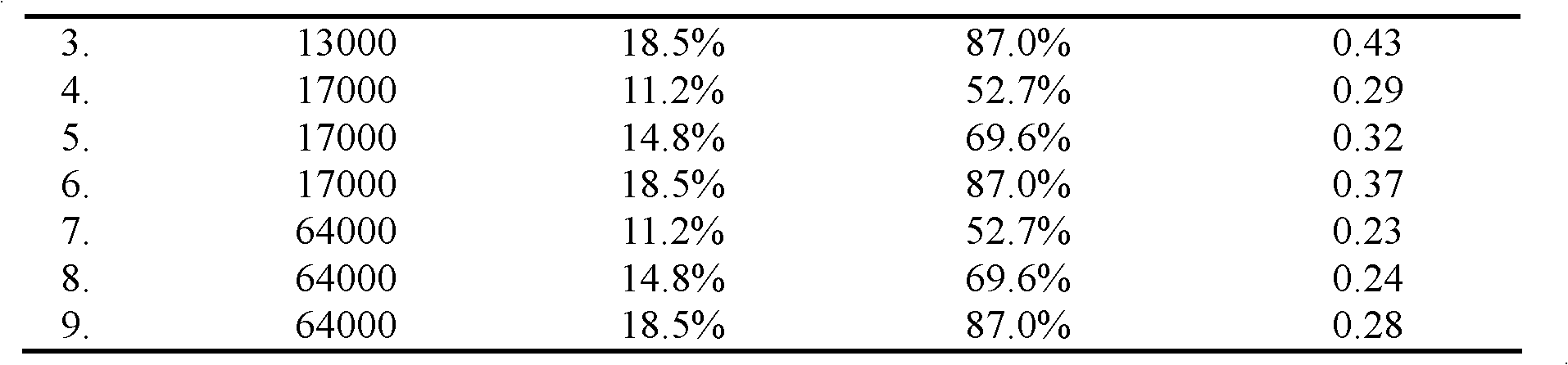

[0022] The water content is 4.7%, the weight average molecular mass (M w ) is 100g (dry basis) of starch of 13000Da in a kneader and the mass percent of stirring and mixing in an ice-water bath is 18.5% NaOH (18.5g), 20.3% water (20.3g) and 87.0% 3-chloro- The mixed system of dihydroxypropyltrimethylammonium chloride (87.0g) was dry-mixed and reacted for 48 hours at a temperature of 25°C and a rotating speed of 100 rpm; After filtering, wash with absolute ethanol until AgNO 3 Check for Cl - Dry at 60° C., crush and pass through an 80-mesh sieve to obtain a quaternary ammonium cationic starch gene controlled-release carrier material with a degree of substitution (DS) of 0.43 (Table 1). Other conditions are constant, change the weight-average molecular weight of starch and the consumption (table 1) of NaOH and 3-chloro-dihydroxypropyltrimethyl ammonium chloride, the quaternary ammonium type cationic starch gene controlled release carrier material of gained different degree of ...

Embodiment 2

[0027] The water content is 13.5%, the weight average molecular mass (M w) is 100g (dry basis) of starch 100g (dry base) of 64000Da in a kneader and the mass percent of stirring and mixing in an ice-water bath is 18.5% KOH (18.5g), 11.5% water (11.5g) and 87.0% 3-chloro- Dihydroxypropyltrimethylammonium chloride (87.0g) mixed system, at a temperature of 30°C and a rotation speed of 40 rpm, dry mixed reaction for 48 hours; after the reaction was complete, the sample was precipitated with absolute ethanol, and suction filtered After that, wash with absolute ethanol until AgNO 3 Check for Cl - Dry at 60° C., crush and pass through an 80-mesh sieve to obtain a quaternary ammonium cationic starch gene controlled-release carrier material with a degree of substitution (DS) of 0.19 (Table 2). Other conditions are constant, change the weight-average molecular weight of starch and the consumption (table 9) of NaOH and 3-chloro-dihydroxypropyltrimethyl ammonium chloride, the quaternary...

Embodiment 3

[0031] The water content is 4.7%, the weight average molecular mass (M w ) is 100g (dry basis) of starch of 17000Da in a kneader and the mass percent of stirring and mixing in an ice-water bath is 18.5% NaOH (18.5g), 20.3% water (20.3g) and 87.0% 3-chloro- Dihydroxypropyltrimethylammonium chloride (87.0g) mixed system, at a temperature of 30°C and a rotation speed of 75 rpm, dry mixed reaction for 48 hours; after the reaction was complete, the sample was precipitated with absolute ethanol, and suction filtered After that, wash with absolute ethanol until AgNO 3 Check for Cl - Dry at 60° C., crush and pass through an 80-mesh sieve to obtain a quaternary ammonium cationic starch gene controlled-release carrier material with a degree of substitution (DS) of 0.35 (Table 3). Other conditions are constant, change the weight-average molecular weight of starch and the consumption (table 3) of NaOH and 3-chloro-dihydroxypropyl trimethyl ammonium chloride, the quaternary ammonium type...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com