Manganese-containing boron iron-based wear-resistant flux-cored wire for surfacing and preparation method of surfacing alloy

A technology of flux-cored welding wire and ferroboron, applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of energy and material consumption, mechanical failure, etc., and achieve the effect of improving wear resistance and hard phase morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

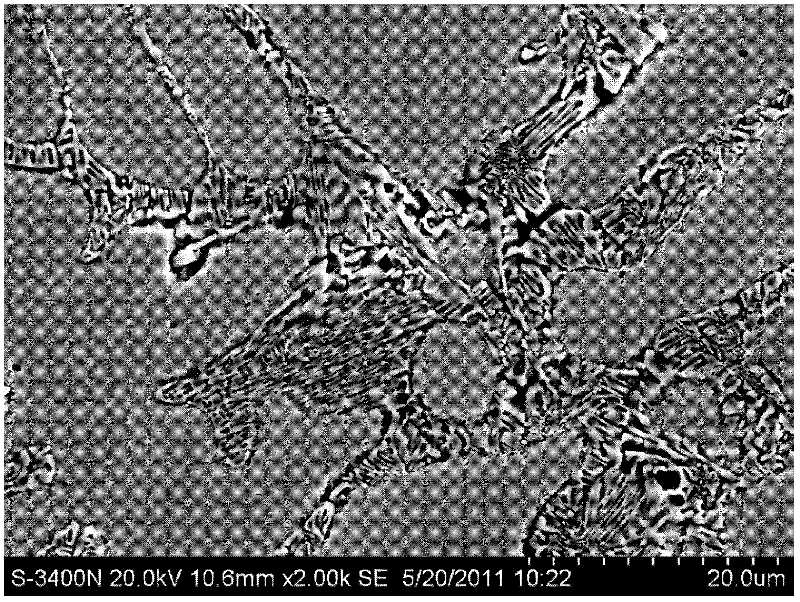

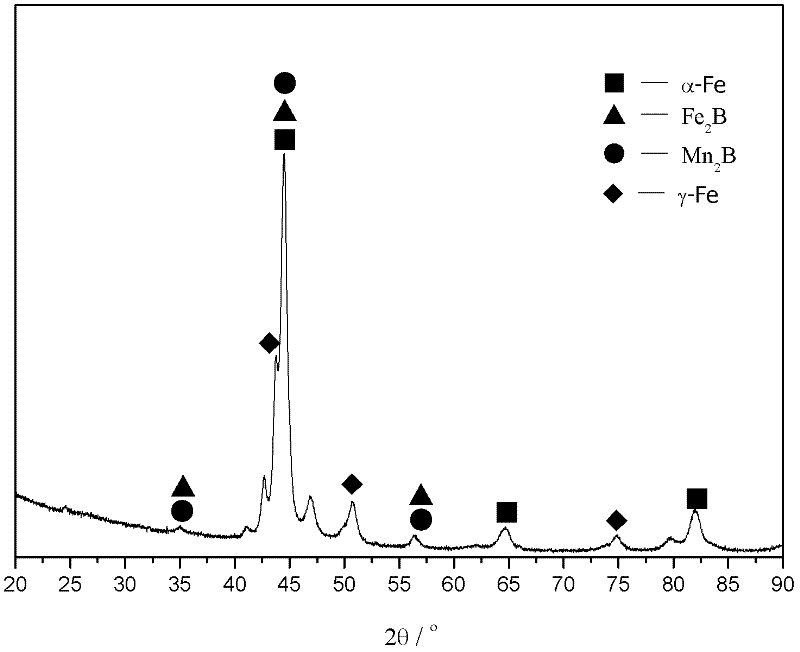

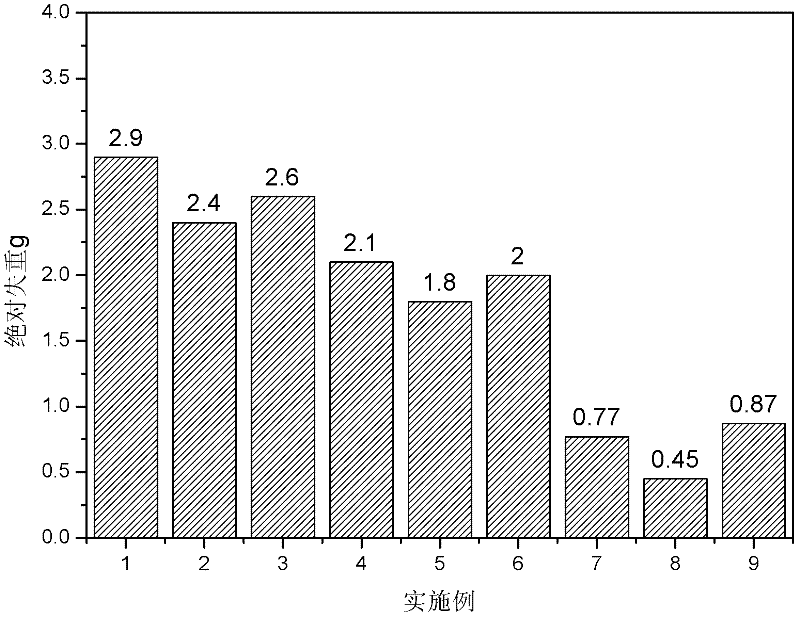

[0026] A manganese-containing and boron-containing wear-resistant surfacing flux-cored welding wire includes SPCC hollow welding wire and a powder flux core. The powder rate was 27%. Set the surfacing welding process parameters as follows: voltage 23-30V; current 200-230A; wire feeding speed: 410-510mm / min; gas flow rate: 18-25L / min; The composition of the surfacing alloy prepared by the above process is: Mn: 5.8wt.%; B: 2.1wt%; C: 0.1wt.%; Fe balance. The average hardness of the obtained surfacing layer is HRC43, and the appearance of the weld seam is beautiful without cracks. see SEM figure 1 , the XRD pattern of the surfacing alloy is shown in figure 2 .

Embodiment 2

[0028] A manganese-containing and boron-containing wear-resistant surfacing flux-cored welding wire includes SPCC hollow welding wire and a powder flux core. The powder rate was 27%. Set the surfacing welding process parameters as follows: voltage 23-30V; current 200-230A; wire feeding speed: 410-510mm / min; gas flow rate: 19-25L / min; The composition of the surfacing alloy prepared by the above process is: Mn: 7.8wt.%; B: 2.1wt%; C: 0.1wt.%; Fe balance. The average hardness of the obtained surfacing layer is HRC46, and the appearance of the welding seam is beautiful without cracks.

Embodiment 3

[0030] A manganese-containing and boron-containing wear-resistant surfacing flux-cored welding wire includes SPCC hollow welding wire and a powder flux core. The powder rate was 27%. Set the surfacing welding process parameters as follows: voltage 23-30V; current 200-230A; wire feeding speed: 410-510mm / min; gas flow rate: 18-25L / min; The composition of the surfacing alloy prepared by the above process is: Mn: 13wt.%; B: 2.1wt%; C: 0.1wt.%; Fe balance. The average hardness of the obtained surfacing layer is HRC44, and the appearance of the welding seam is beautiful without cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com