Special bracket for continuously casting long nozzle

A shroud and bracket technology, which is applied to casting equipment, casting melt containers, metal processing equipment, etc., can solve the problems of unsuitable shrouds, etc., and achieve the effect of good flexibility and convenient loading, unloading and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

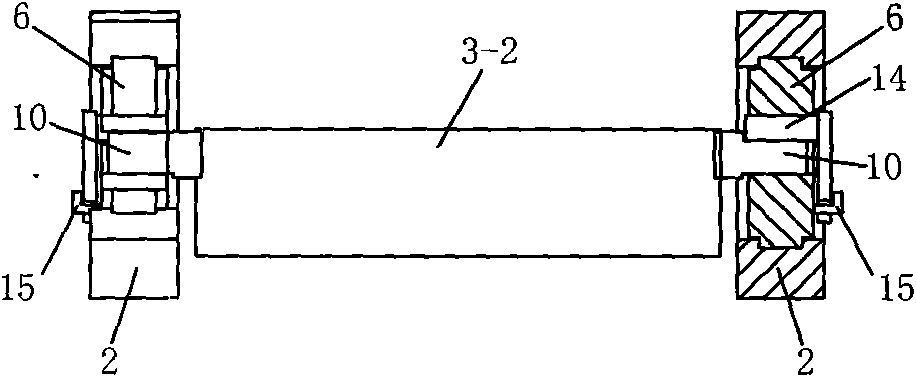

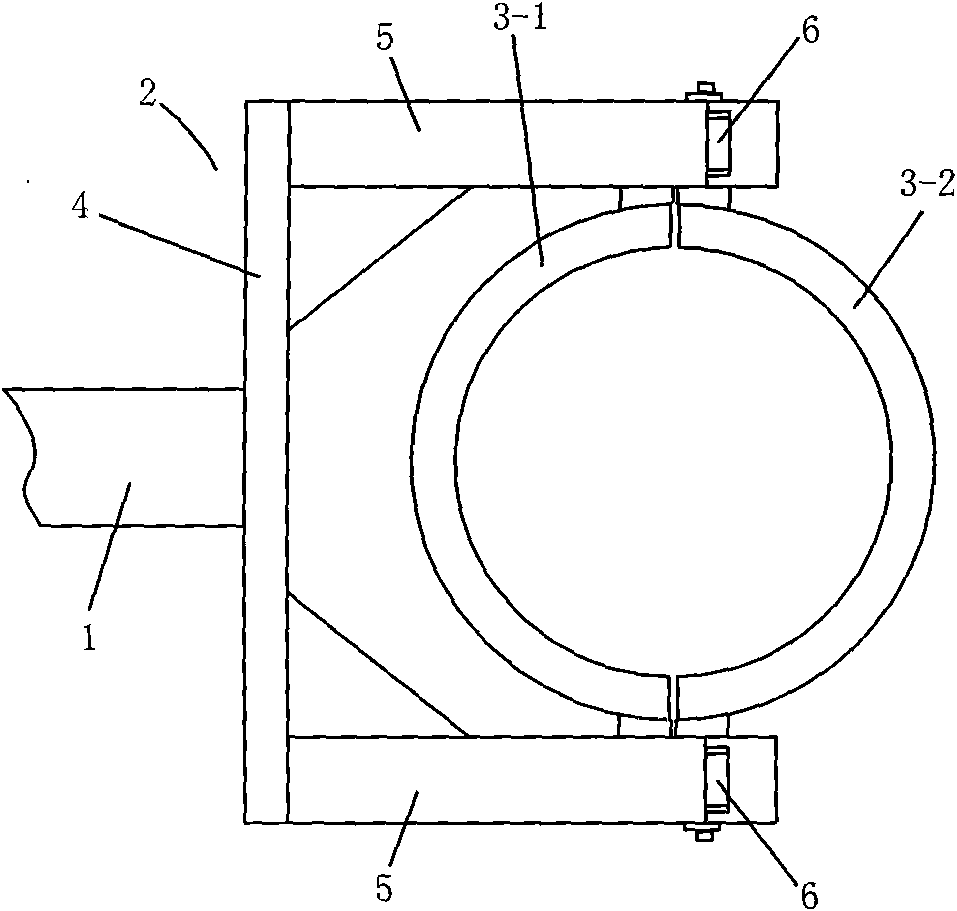

[0036] The special bracket for continuous casting shroud in this embodiment is as follows: figure 1 , figure 2 and image 3 As shown, it includes a support platform 2 arranged at the end of the manipulator cantilever 1 and support rings 3-1 and 3-2 divided into two halves. The support platform 2 is mainly composed of a base plate 4 and two support plates symmetrically fixed on both sides of the base plate 4 5 forms the C font that surrounds one 3-1 of two half support circles. Such as figure 1 and Figure 4 As shown, one end of supporting plate 5 is made into a Y-shaped opening, and a rotating seat 6 is stuck in the Y-shaped opening. Such as Figure 4 and Figure 5 Shown, be shaped on arc groove 7 in Y font opening; Figure 6 and Figure 7 As shown, the outer surface of the rotating seat 6 is formed with an arc-shaped convex line 8 matching the arc-shaped groove 7 . Such as Figure 4 and Figure 6 As shown, the minimum outer diameter D of the rotating seat 6 1 Sma...

Embodiment 2

[0040] The special bracket for the continuous casting shroud in this embodiment is an improvement on the basis of the first embodiment, except that it is the same as the first embodiment except that the structure of the pin 14 is replaced by a new pin 16 . New latch 16 as Figure 16 and Figure 17 As shown, the new pin 16 is also formed L-shaped by the new pin shaft 16-1 and the new pin handle 16-2 that intersect perpendicularly. The difference between the new pin 16 and the pin 14 of embodiment one is: 1) the new pin shaft 16-1 Section is big semicircle (certainly also can be small semicircle, positive semicircle or near semicircle etc.), the section of new bearing pin 16-1 is less than or equal to the section of the second half slot 12 and greater than the first The section of half slot 11; 2) new pin handle 16-2 bottom is shaped on a gap 17, can limit new bearing pin 16-1 to rotate counterclockwise. When the new latch 16 of the present embodiment is assembled as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com