Oil-resistant sealant and its preparation method

A sealant and oil-resistant technology, applied in the field of oil-resistant sealants and their preparation, can solve the problems of poor air tightness and water tightness, poor oil resistance, low bonding strength, etc., and achieve low air permeability and stable product dimensions. Good performance and excellent water tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

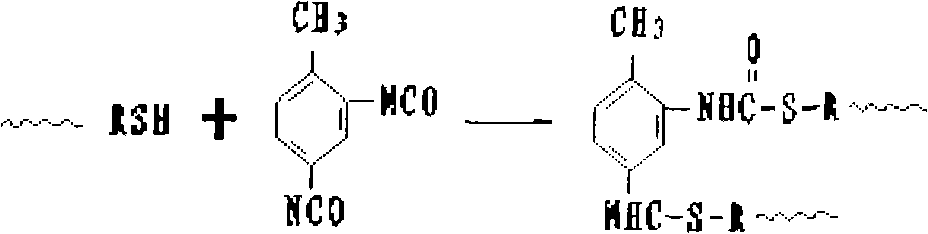

Method used

Image

Examples

Embodiment 1

[0023] In an environment with a temperature of 20±5°C and a humidity of 70% to 80%, weigh the weight of isocyanate and epoxy resin carrier, dibutyltin dilaurate or triethylenediamine as the catalyst according to any specific value in the above weight percentage The percentage content is used to prepare the sealant. The specific method can be, weigh 10wt% of E-51 epoxy resin, 67wt% of liquid JLY-121 polysulfide rubber, and 20wt% of polymethyl polyphenyl diisocyanate; then put the above-mentioned weighed raw materials in a glass container In a medium, such as a beaker, stir well with a glass rod, drop 3wt% of dibutyltin dilaurate or triethylenediamine, stir well again, and place it in the same room temperature environment for 5min.

Embodiment 2

[0025] In an environment with a temperature of 20±5°C and a humidity of 70% to 80%, put the epoxy resin, liquid polysulfide rubber, and isocyanate into a glass container according to the components specified in Table 1, and stir well with a glass rod. Then add the catalyst dropwise, stir well again, and place it under the same normal temperature environment for 5 minutes to make a sealant composition.

Embodiment 3

[0027] The method of Experimental Example 2 was repeated at the contents of each combination specified in Table 1, but dibutyltin dilaurate was replaced with triethylenediamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com