Anti-welding adhesive tape

A tape and anti-soldering technology, applied in the direction of adhesives, film/sheet adhesives, layered products, etc., can solve the problems of scrapped printed circuit boards, exposed small holes of printed circuit boards, prone to shrinkage and falling off, etc. Achieve good tearability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to make a clearer and clearer definition of the protection scope of the present invention.

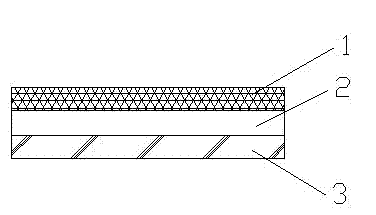

[0013] See figure 1 As shown, the embodiment of the present invention includes:

[0014] A solder mask tape, comprising a substrate film layer 2, a reinforcing tape 3 and a pressure-sensitive layer 1, wherein the reinforcing tape 3 is coated on one side surface of the substrate film layer 2, and the pressure-sensitive The layer 1 is coated on the other side surface of the base film layer 2.

[0015] The base film layer 2 is a polyimide film layer, which has outstanding high temperature resistance, radiation resistance, chemical corrosion resistance and electrical insulation properties, and can be used for a long time in the air at 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com