High-frequency flutter cold extruding die

A technology of cold extrusion and flutter, applied in the direction of metal extrusion dies, etc., can solve the problems that large-scale parts cannot be vibrated at high frequencies, and the dimensional accuracy of formed parts cannot be guaranteed, and achieve simple structure, large output force, Effect of High Vibration Frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings.

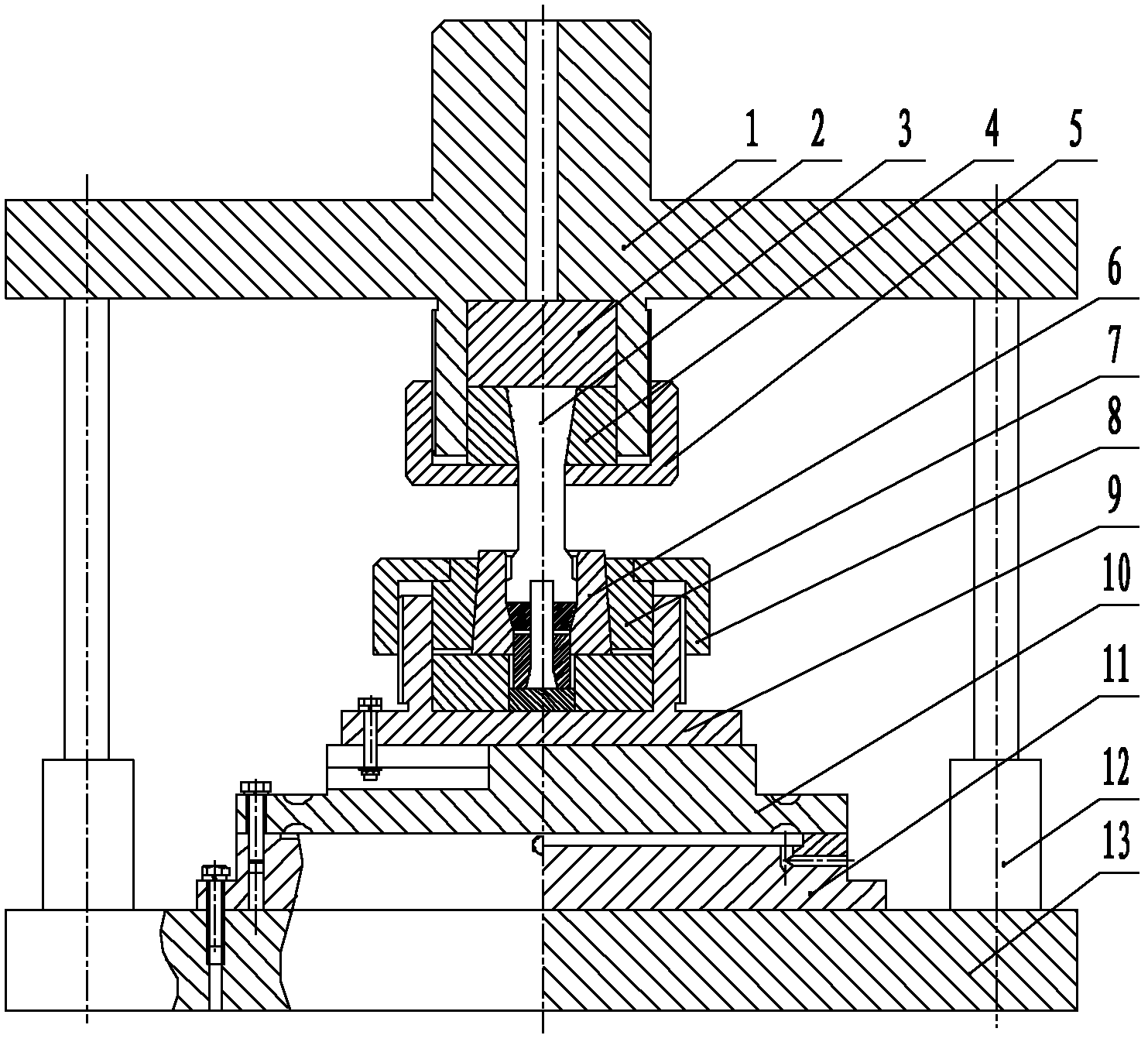

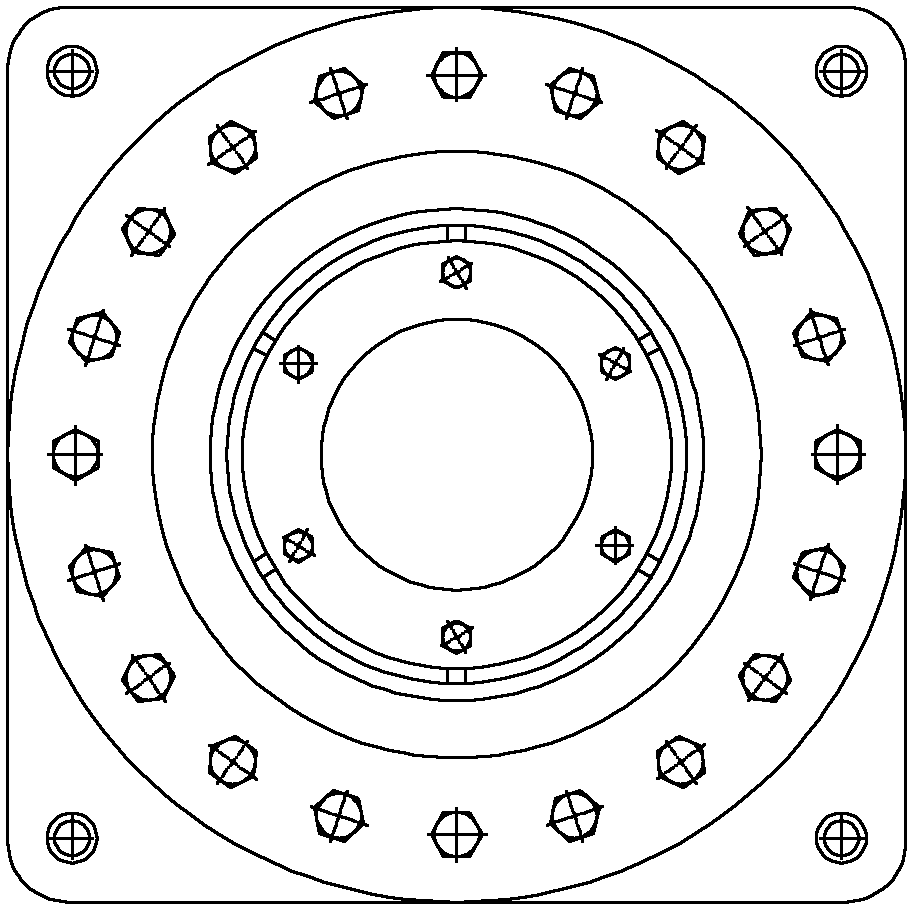

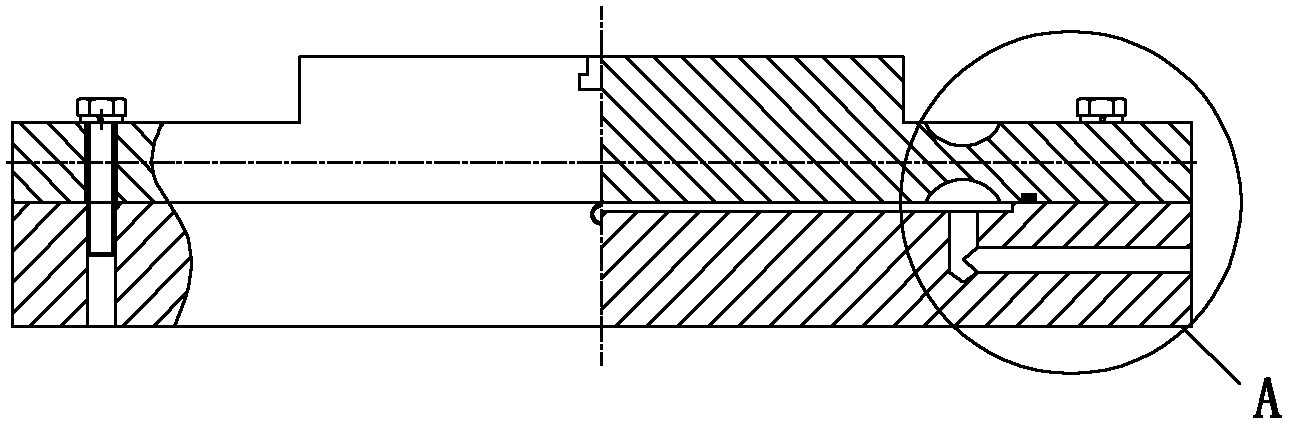

[0028] Reference Figure 1 ~ Figure 7 , A high-frequency flutter cold extrusion die, including a forming mechanism, the forming mechanism includes a male mold 3 and a female mold 6, the male mold 3 is fixedly connected to the upper mold plate 1, and the female mold 6 is located in the male mold 3. Immediately below, the die 6 is installed in the die sleeve 9. The high-frequency flutter cold extrusion die also includes a flutter generating mechanism that includes a vibrating table and a high-frequency valve. The vibrating table includes an upper plate 10 and a lower plate 11. The upper plate 10 is provided with a boss in the middle, and the boss is fixedly connected to the female mold sleeve 9, and the upper plate around the boss is provided with a vertically symmetrical annular groove 14. The cross-section of the annular groove 14 is arc-shaped, and a lower groove is provided in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com