Lithium ion secondary battery porous multilayer diaphragm and manufacture method thereof

A secondary battery and lithium-ion technology, which is applied in the field of lithium-ion batteries, can solve the problems of poor consistency of diaphragm thickness and complicated process, and achieve the effects of improving porosity, ensuring safety, and ensuring permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

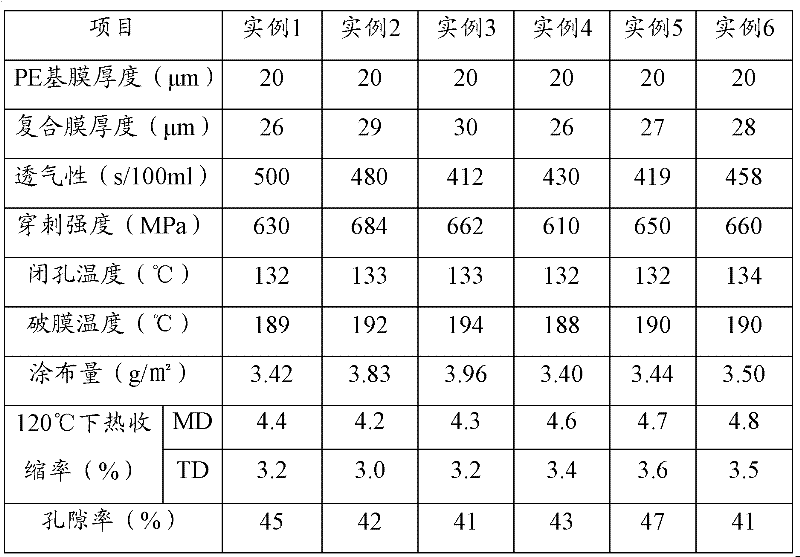

Examples

Embodiment 1

[0038] Add 10g of polyethylene terephthalate (PET, melting point 256-265°C) into a beaker containing 100g of N,N-dimethylformamide (DMF) solvent, heat to 80°C, and stir Stir slowly until the resin dissolves. Add 10g of magnesium oxide (MgO, with an average particle size of 500nm) into the above solution evenly, stir evenly, and continue to stir for 60 minutes to obtain a uniform suspension. During the stirring process, the mouth of the beaker should be sealed to reduce the volatilization of the solvent. Heat the polyethylene microporous base film with a thickness of 20 μm and a porosity of 50% to 100°C, and apply the above suspension on the polyethylene microporous base film at a coating speed of 5 cm / s by scraping. On the porous base film, the temperature for controlling the volatilization of the solvent is 80°C, and the time for controlling the volatilization of the solvent by blowing is 60S; then the above-mentioned coating steps are carried out on the side that is not coat...

Embodiment 2

[0040] Add 10 g of polyacrylonitrile into a beaker containing 100 g of N,N-dimethylformamide (DMF) solvent, heat to 80° C., and stir slowly with a stirrer until the resin dissolves. 10g of alumina (Al 2 o 3 , with an average particle size of 500nm) evenly added to the above solution, stirred evenly, and continued to stir for 60 minutes to obtain a uniform suspension. During the stirring process, the mouth of the beaker should be sealed to reduce the volatilization of the solvent. The polyethylene microporous base film with a rate of 50% was heated to 100°C, and the above suspension was coated on the polyethylene microporous base film at a coating speed of 5 cm / s by scraping, The temperature for controlling the volatilization of the solvent is 80°C, and the time for controlling the volatilization of the solvent by blowing is 100 seconds; then the above-mentioned coating steps are carried out on the side that is not coated with the suspension, so that both sides are uniformly a...

Embodiment 3

[0042] Add 10g of polyvinylidene fluoride into a beaker containing 100g of N-methylpyrrolidone solvent, heat to 80°C, and stir slowly with a stirrer until the resin dissolves. 20g of silicon dioxide (SiO 2 , with an average particle size of 500nm) evenly added to the above solution, stirred evenly, and continued to stir for 60 minutes to obtain a uniform suspension. During the stirring process, the mouth of the beaker should be sealed to reduce the volatilization of the solvent. The polyethylene microporous base film with a rate of 50% was heated to 100°C, and the above suspension was coated on the polyethylene microporous base film at a coating speed of 5 cm / s by scraping, The temperature for controlling the volatilization of the solvent is 80°C, and the time for controlling the volatilization of the solvent by blowing is 60S; then carry out the above-mentioned coating steps on the side that is not coated with the suspension, so that both sides are uniformly attached with hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com