Method for preparing medical high molecular material by magnetron sputtering technology

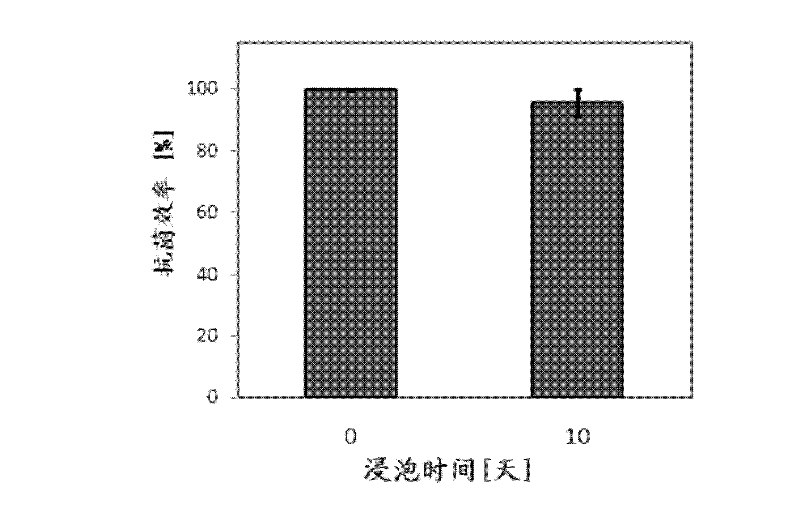

A polymer material, magnetron sputtering technology, applied in the field of medical polymer material processing, to achieve the effect of prolonged antibacterial effect, broad-spectrum anti-infection performance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

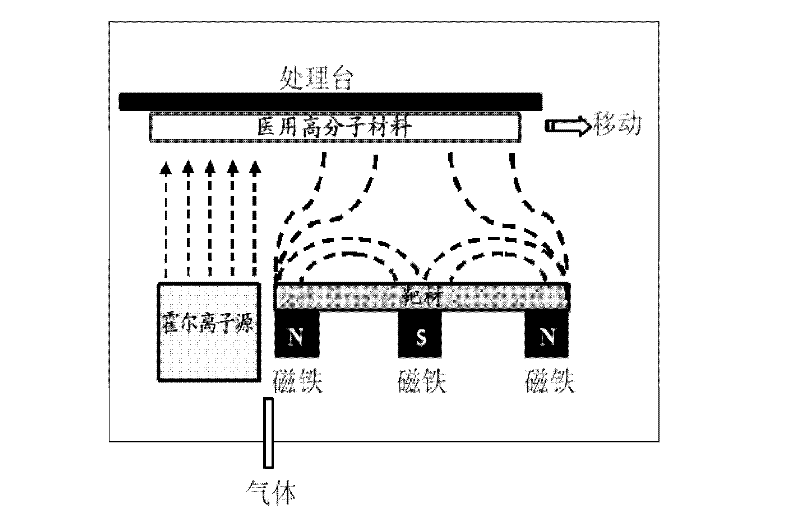

[0039] The preparation of medical polymer materials by magnetron sputtering technology includes the following steps:

[0040]Move the PE non-woven wound dressing with a thickness of 1 μm through the processing table in the vacuum chamber of the magnetron sputtering equipment at 4 m / min, and install a silver target on the target table. The PE non-woven wound dressing and the magnetic The distance between the sputtering targets is 6cm, and then the vacuum chamber of the equipment is sealed, and the vacuum is evacuated to 1×10 -5 At Pa, nitrogen gas of 20.0 SCCM and argon gas of 20.0 SCCM are introduced to finally maintain the working vacuum at about 0.5 Pa, turn on the power of the processing table, control the temperature of the processing table at about 50°C, and turn on the Hall plasma source with a power of 300W, turn on the pulse current of the target platform, the magnitude is 1A, after the treatment, turn off the power supply of the treatment platform and the target platf...

Embodiment 2

[0043] The preparation of medical polymer materials by magnetron sputtering technology includes the following steps:

[0044] Fix the PLA film with a thickness of 0.5 μm on the processing table in the vacuum chamber of the magnetron sputtering equipment, install the silver target and the zinc target on the target table, the PLA film and the magnetron sputtering target The distance is 20cm, then seal the equipment vacuum cavity, and evacuate to 5×10 -4 At Pa, feed 10.0SCCM of ammonia gas, 10.0SCCM of acetic acid gas and 20.0SCCM of argon gas to finally maintain the working vacuum at about 10Pa, turn on the power of the processing table, control the temperature of the processing table at about 60°C, and turn on the radio frequency plasma Body source, the power is 500W, after 5 minutes of treatment, turn on the direct current of the target platform, the size is 10A, after 5 seconds of treatment, turn off the power supply of the treatment platform, target platform and radio freque...

Embodiment 3

[0047] The preparation of medical polymer materials by magnetron sputtering technology includes the following steps:

[0048] Move the PA-66 artificial intervertebral body support body through the processing table in the vacuum chamber of the magnetron sputtering equipment at 2 m / min, and install a silver target, a zinc target and a phosphorus target on the target table, PA The distance between the -66 artificial vertebral body support and the magnetron sputtering target is 5.0cm, and then the vacuum chamber of the equipment is sealed and evacuated to 5×10 -4 Pa, through 20.0SCCM of nitrogen, 5.0SCCM of acetylene gas and 15.0SCCM of argon, and finally maintain the working vacuum at 1×10 -1 At about Pa, turn on the power of the processing table, control the temperature of the processing table at about 120°C, turn on the Hall plasma source, the power is 800W, turn on the pulse current of the target stage, the magnitude is 200mA, after the processing is completed, turn off the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com