Magnesium-based hydrogen storage material with added rare earth element and preparation method thereof

A technology for rare earth elements and hydrogen storage materials, applied in non-metallic elements, chemical instruments and methods, hydrogen and other directions, can solve the problems of unfavorable practical application of magnesium-based alloys, complicated methods of magnesium nano-powder, and low yield, etc., and achieve good hydrogen storage. Effects of kinetic performance, increased speed, low operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 19g of Mg and 1g of Nd, thoroughly mix and grind them in a mortar (the particle diameter is 75-100 microns), and press them in a hydraulic tablet press to obtain a block at a pressure of 15 MPa, which is used as an anode.

[0021] The block of magnesium metal and rare earth element Nd is used as the anode, and the tungsten rod is used as the cathode, and placed in a DC arc plasma equipment with a current of 150A. When the equipment is pumped to a vacuum of 2×10 -2 Pa, fill in argon gas to 0.8 atm, after the arc starts, continue to pass argon gas to 1 atm to react for 10 minutes, extinguish the arc, pass cooling water to cool the reaction temperature to room temperature, and the water pressure is 2Mpa; vacuum the DC arc plasma equipment to 2×10 -2 Pa, and then filled with argon gas 0.7atm and air 0.3atm for passivation operation; after passivation, collect the inner wall powder, which is the prepared magnesium-based hydrogen storage material. TEM figure 1 The disp...

Embodiment 2

[0023] Take 18g of Mg and 2g of La, fully mix and grind them in a mortar (the particle diameter is 75-100 microns) and press them in a hydraulic tablet press to obtain a block at a pressure of 15 MPa, which is used as an anode.

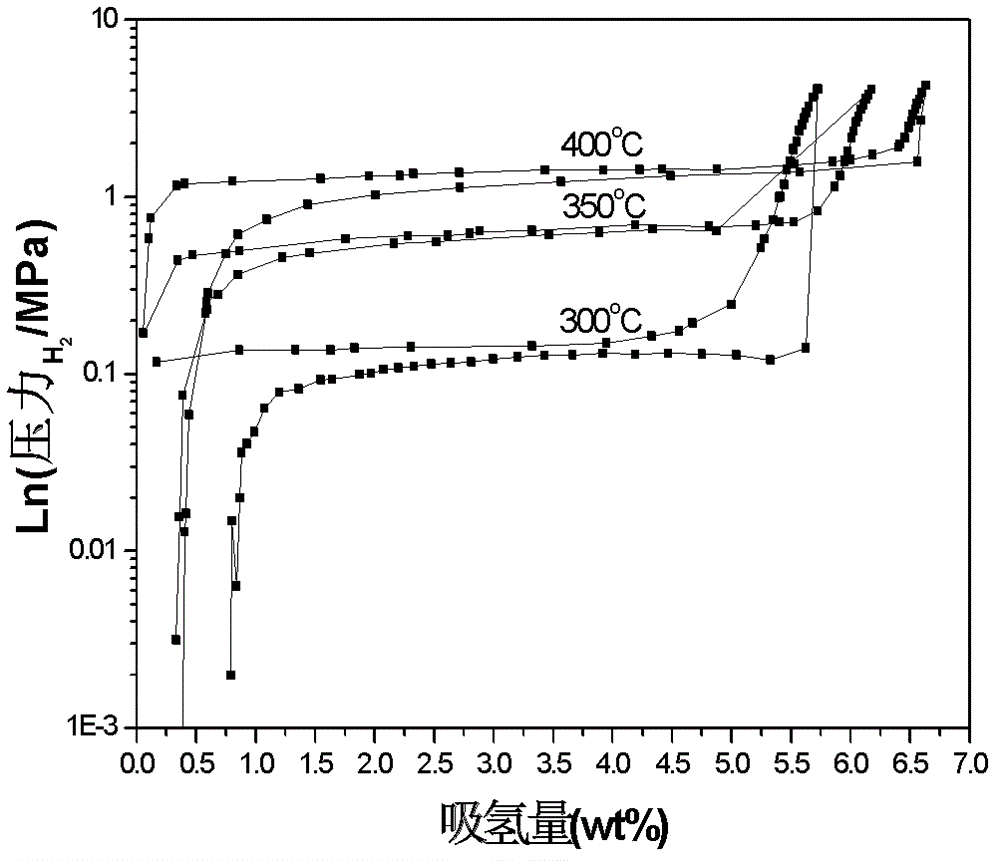

[0024] The block of magnesium metal and rare earth element La is used as the anode, and the tungsten rod is used as the cathode. Placed in a DC arc plasma device with a current of 150A, when the device is pumped to a vacuum of 2×10 -2 Pa, fill in argon gas 0.7atm and hydrogen gas 0.1atm, after arcing, continue to pass hydrogen gas to 1atm, react for 10 minutes, extinguish the arc, pass cooling water to cool the reaction temperature to room temperature, water pressure 2MPa; DC arc plasma The equipment is evacuated to 2×10 -2 Pa, and then filled with argon gas 0.7atm and air 0.3atm for passivation operation; after passivation, collect the inner wall powder, which is the prepared magnesium-based hydrogen storage material. PCT figure 2 The hydrogen ab...

Embodiment 3

[0026] Take 16.5g of Mg and 3.5g of Er, thoroughly mix and grind them in a mortar (the particle diameter is 75-100 microns), and press them in a hydraulic tablet press to obtain a block at a pressure of 15 MPa, which is used as an anode.

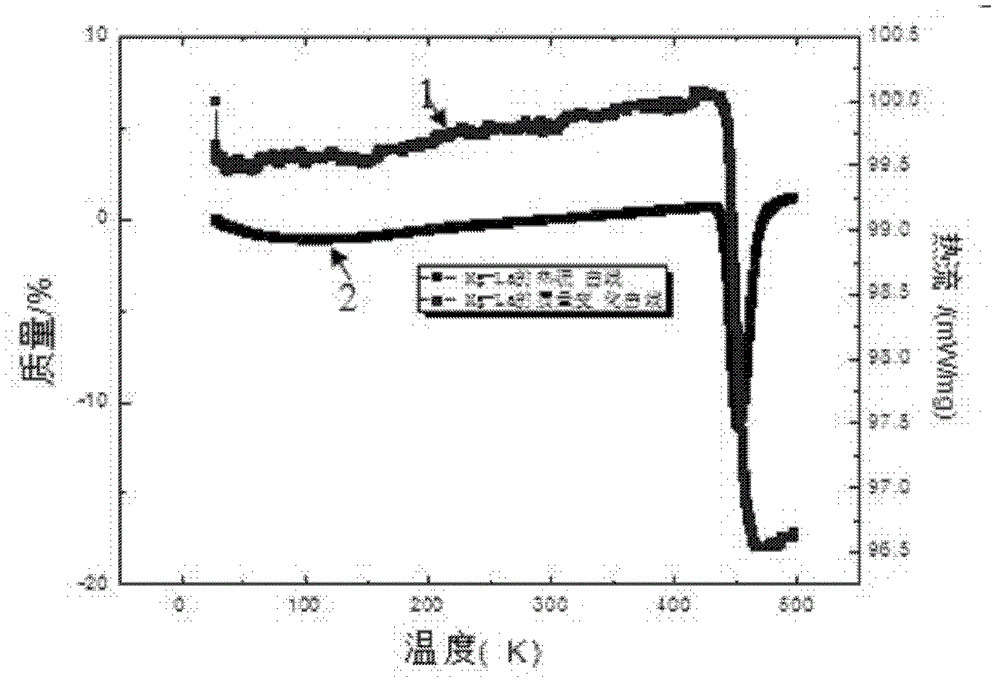

[0027] The block of magnesium metal and rare earth element Er is used as the anode, and the tungsten rod is used as the cathode. Placed in a DC arc plasma device with a current of 150A, when the device is pumped to a vacuum of 2×10 -2 Pa, filled with argon gas 0.8atm, after arcing, continue to pass hydrogen to 1atm, react for 10 minutes, extinguish the arc, pass cooling water to cool the reaction temperature to room temperature, water pressure 2MPa; vacuum the DC arc plasma equipment to 2×10 -2 Pa, and then filled with argon gas 0.7atm and air 0.3atm for passivation operation; after passivation, collect the inner wall powder, which is the prepared magnesium-based hydrogen storage material. PCT Figure 4 The hydrogen absorption results sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com