Surface catalyzed high activity magnesium-base hydrogen storing material and preparing method thereof

A technology for surface catalysis and hydrogen storage materials, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of reducing the hydrogen storage capacity of materials, unfavorable practical application of magnesium-based alloys, loss of mechanical energy, etc. , to achieve the effect of high hydrogen storage capacity and good hydrogen storage kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Magnesium metal powder is purchased commercially, and the catalyst used in the test is prepared as follows: the design alloy composition is Ti-15Mn-15Cr-25V-5Fe, and the purity of each elemental raw material is all above 99.5%. Repeated melting for 4 times on the frequency magnetic levitation melting furnace to ensure the uniformity of the alloy. The obtained alloy is the as-cast alloy.

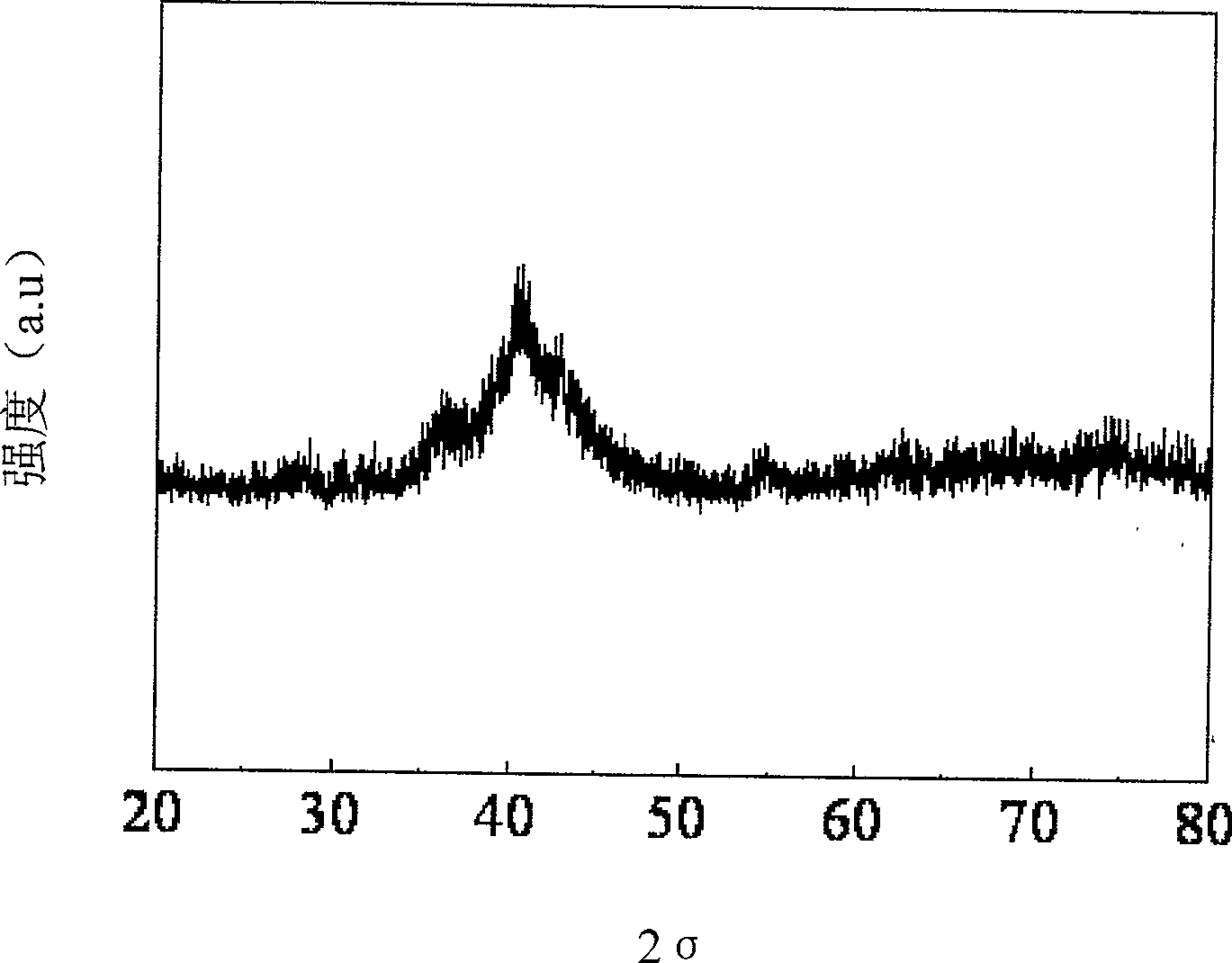

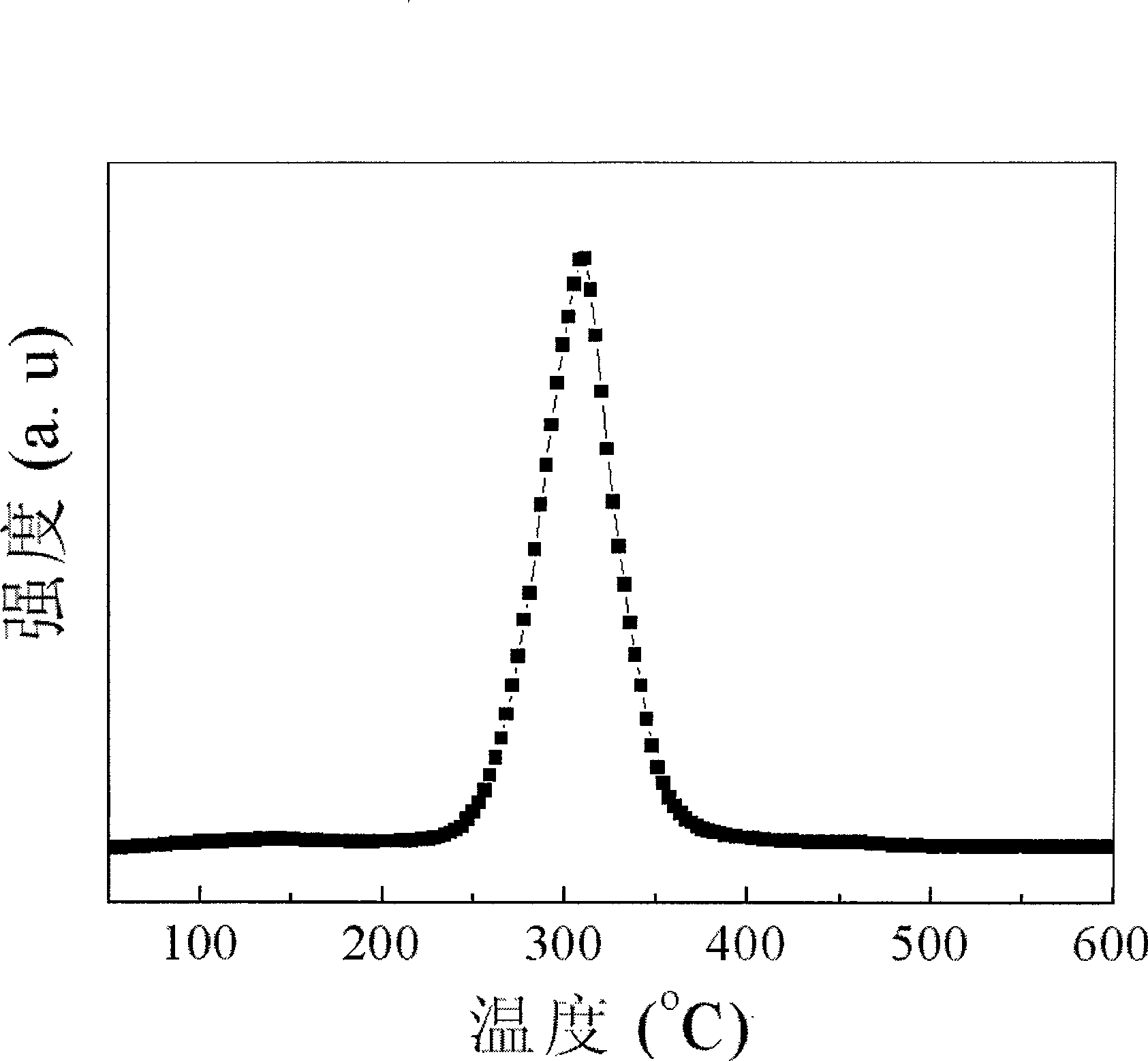

[0023] The preparation of the high-activity magnesium-based alloy is as follows: the magnesium powder is mixed with 50wt% of Ti-15Mn-15Cr-25V-5Fe and then ball milled for 5 hours under hydrogen atmosphere. figure 1 It is the X-ray diffraction pattern after ball milling. It can be seen that the alloy has become amorphous after 5 hours of ball milling. figure 2 The mass spectrometry results show that the initial hydrogen desorption temperature of magnesium powder modified by BCC alloy is reduced to about 250 °C.

Embodiment 2

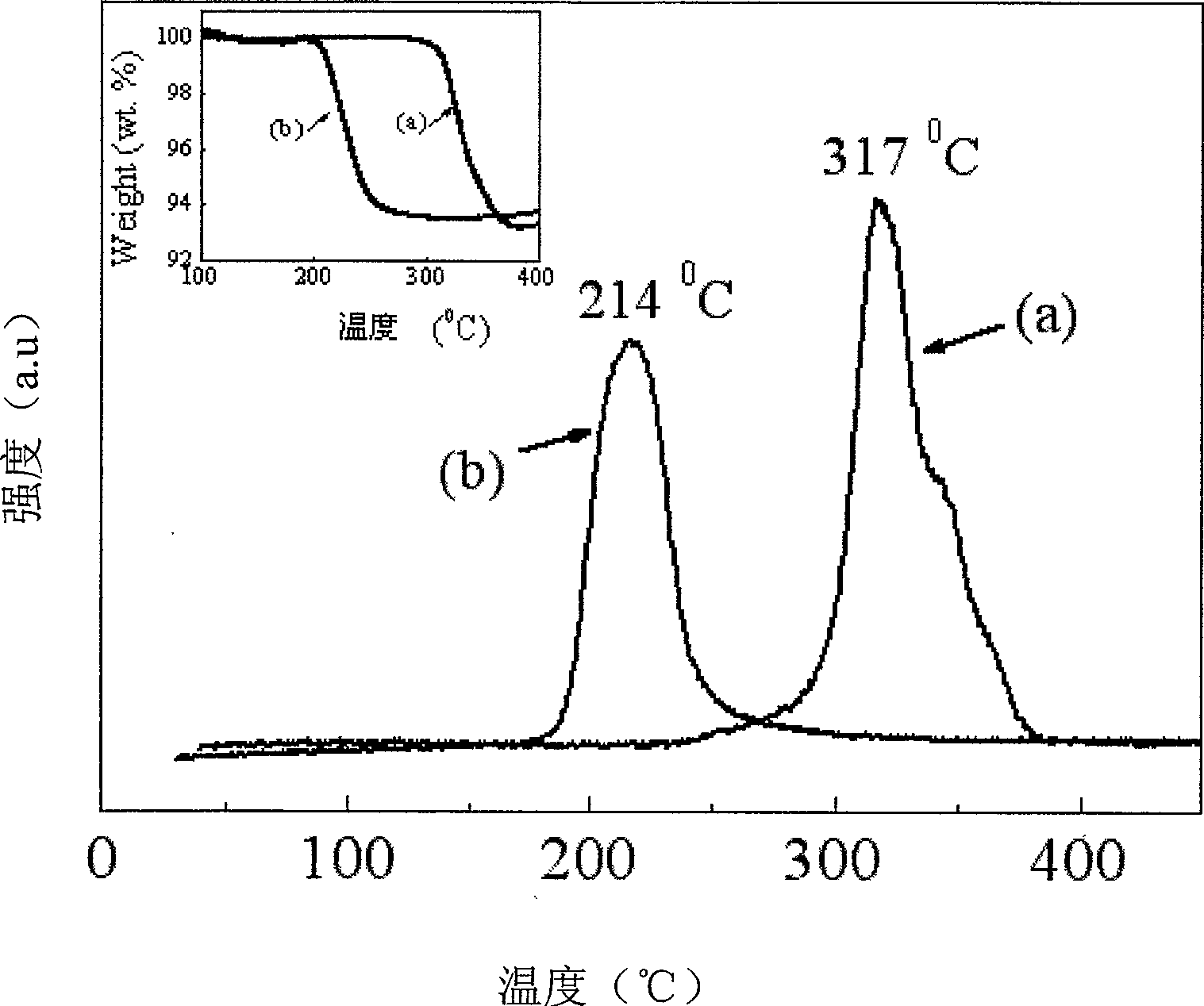

[0024] Example 2: The catalyst alloy composition is designed to be Ti-15Mn-15Cr-30V, and the purity of each elemental raw material is above 99.5%. A 50-gram sample is repeatedly smelted 4 times on a high-frequency magnetic levitation melting furnace to ensure that the alloy is uniform . The obtained as-cast alloy was hydrogenated for 2 hours at room temperature and under a hydrogen atmosphere of 10 atmospheres, and the obtained BCC alloy after absorbing hydrogen was the hydrogenated BCC alloy. Single magnesium powder and magnesium powder+20wt% hydrogenated BCC alloy mixture were ball milled under hydrogen atmosphere for 1 hour. image 3 It is the hydrogen release characteristic curve of magnesium powder and magnesium + BCC alloy after ball milling for 2 hours. It can be seen that the initial hydrogen release temperature of single magnesium powder after ball milling in hydrogen atmosphere is still about 300 ° C, while the hydrogenated BCC alloy modified The initial hydrogen de...

Embodiment 3

[0025] Example 3: The catalyst alloy composition is designed to be Ti-10Mn-15Ni-35V, and the purity of each elemental raw material is above 99.5%. A 50-gram sample is repeatedly smelted 4 times on a high-frequency magnetic levitation melting furnace to ensure that the alloy is uniform . The obtained as-cast alloy was hydrogenated at room temperature under a hydrogen atmosphere of 10 atmospheres for 2 hours. The single magnesium powder and the mixture of magnesium powder+5wt% hydrogenated BCC alloy were ball milled under hydrogen atmosphere for 2 hours. Figure 4 It is a scanning electron microscope picture of magnesium+BCC alloy after ball milling for 2 hours. It can be seen that after ball milling, BCC alloy is evenly distributed on the surface of magnesium, and the average particle size is less than 1 micron. Figure 5 The PCT results showed that the Mg-based alloy showed good PCT properties at 230 °C, 250 °C and 280 °C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com