Magnetic annealing furnace for magnetic conductive iron core

A technology of conducting magnets and magnetic retreat, which is applied in the manufacture of inductors/transformers/magnets, furnaces, furnace types, etc., can solve the problems of reducing production efficiency, large equipment investment, waste of manpower, material resources and time, etc., to improve the permeability, Enhanced magnetic permeability and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

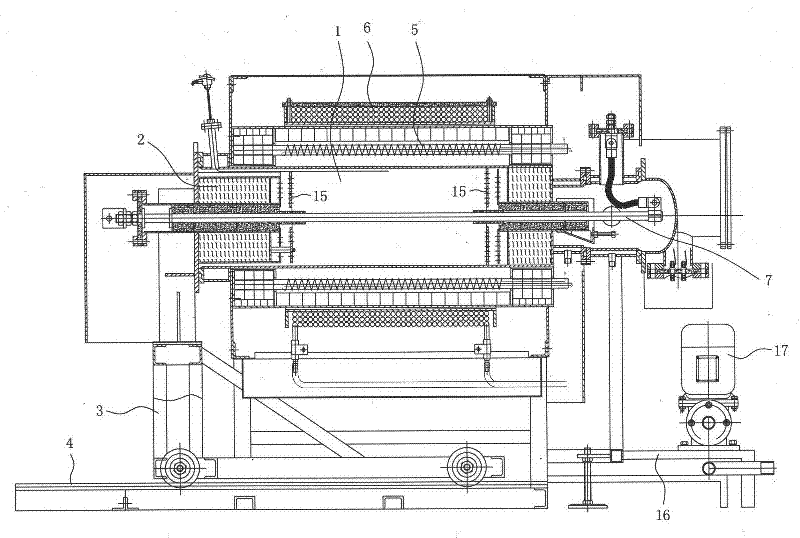

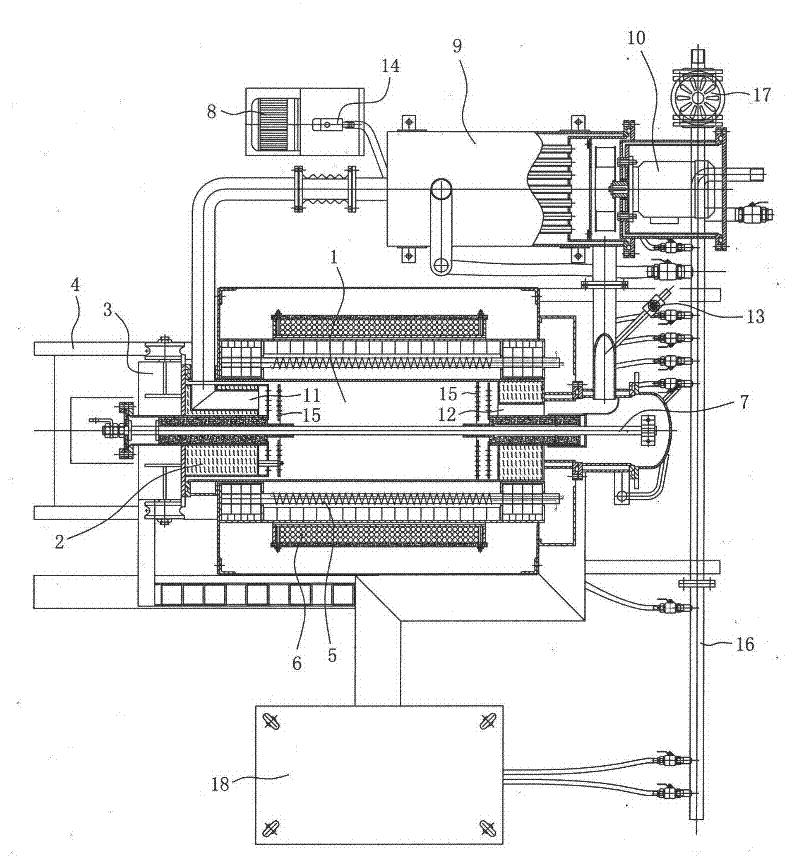

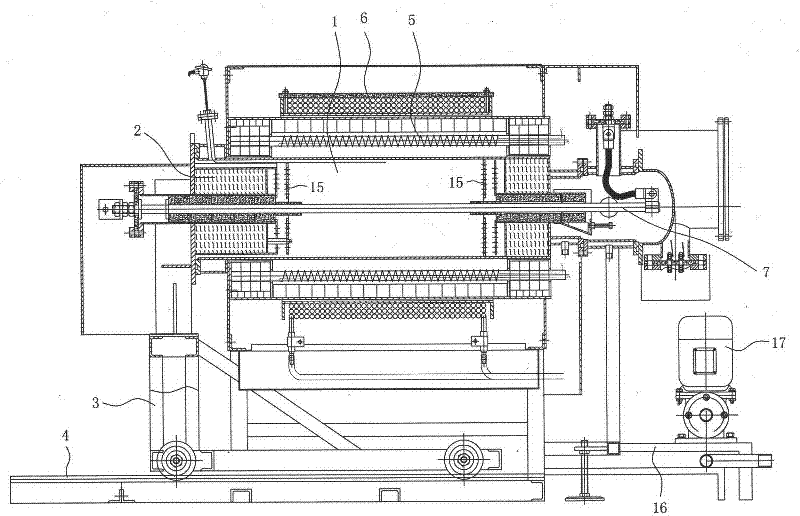

[0015] Below in conjunction with accompanying drawing, the utility patent is further described.

[0016] The permeable core magnetic annealing furnace of the present embodiment includes a furnace body 1, a furnace cover 2 and a dolly 3 that drives the switch of the furnace cover 2, the furnace cover 2 is installed on the dolly 3, and a track 4 is arranged at the bottom of the furnace body 1, The wheels of the trolley are arranged on the track 4, and the switch of the furnace cover 2 is controlled by manually pulling the trolley 3 to slide. The furnace body 1 is provided with a heating device, which is a heating wire 5, and the heating wire 5 is wound in the wall of the furnace body 1. A transverse magnetic generator and a longitudinal magnetic generator are arranged in the furnace body 1. The transverse magnetic generator is a copper tube 6 wound and distributed along the circumference of the furnace body 1, and the longitudinal magnetic generator is a copper rod 7 passing alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com