Water-soluble tracing polymer oil displacement agent and preparation method thereof

A technology of polymer and oil-displacing agent, applied in the field of water-soluble tracer polymer oil-displacing agent and its preparation, can solve the problems such as no literature report, and achieve viscosity increase, good temperature and salt resistance and shear resistance , the effect of rigidity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The synthesis of embodiment 1 AM / NaAA / AMCO polymer

[0021] Add 0.0108 g AMCO, 0.001 g OP-10 emulsifier and 20 g deionized water into a 100 mL single-necked bottle equipped with electromagnetic stirring, stir well and add 8.0 g acrylamide, 2.0 g acrylic acid and 1.11 g hydroxide Sodium, made into a 20% aqueous solution of the total mass percentage concentration of the monomer, adjusting the pH of the system to be 8, and passing N 2 20 min; then add initiator ammonium persulfate solution and sodium bisulfite solution, the ratio of ammonium persulfate to sodium bisulfite is 1:1, the amount added is 1% of the total mass of the monomer, continue Access to N 2 20 min, react at a temperature of 50°C for 8h, after the reaction, the polymer is purified with absolute ethanol, the precipitate is cut into small particles, and dried at 40°C for 2 days to obtain AM / NaAA / AMCO polymer, AM / NaAA / AMCO polymer The amount of medicine required for synthesis is shown in Table 1 below: ...

Embodiment 2

[0024] Structural characterization of embodiment 2 AM / NaAA / AMCO polymer

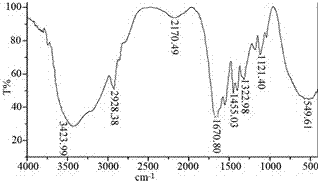

[0025] The infrared spectrogram of the polymer AM / NaAA / AMCO of embodiment 1 is as figure 1 As shown, it is known from the figure that N-H (-NH 2 ) stretching vibration peak at 3423.99cm -1 , the -C=O stretching vibration peak is at 1670.80cm -1, C-O (C-O-C) stretching vibration peak at 1121.40 cm -1 place.

Embodiment 3

[0026] Embodiment 3 The relationship between the fluorescent intensity of AM / NaAA / AMCO polymer and its concentration

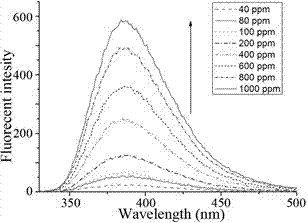

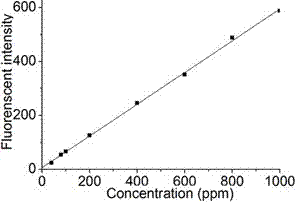

[0027] Under the condition that the excitation wavelength and emission wavelength of AM / NaAA / AMCO polymer are 321nm and 383nm respectively, the emission spectrum of AM / NaAA / AMCO polymer with a concentration of 40-1000 ppm is scanned as figure 2 shown by figure 2 It can be seen that the relative fluorescence intensity of the polymer increases with the increase of its mass concentration, and the relationship between the concentration of AM / NaAA / AMCO polymer and its fluorescence intensity is as follows: image 3 shown by image 3 It is known that the concentration of the polymer has a good linear relationship with its fluorescence intensity, the linear relationship is y=5.81013+0.58817x, and the linear relationship coefficient can reach 0.99955, indicating that the fluorescence intensity of the AM / NaAA / AMCO polymer can be directly measured. polymer concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com