Method for preparing plastic filler from waste residue in crystal industry

A technology for plastic fillers and waste residues, applied in fibrous fillers, dyeing physical treatment, dyeing organosilicon compound treatment, etc., can solve the problem of not recycling crystal waste residues, etc., achieve good economic benefits, save mining, and small particle fineness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

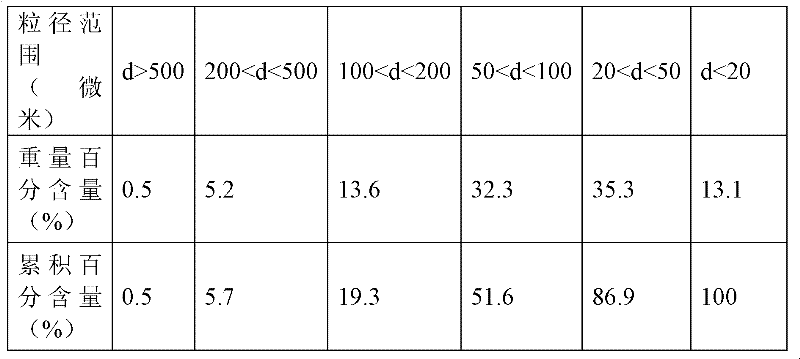

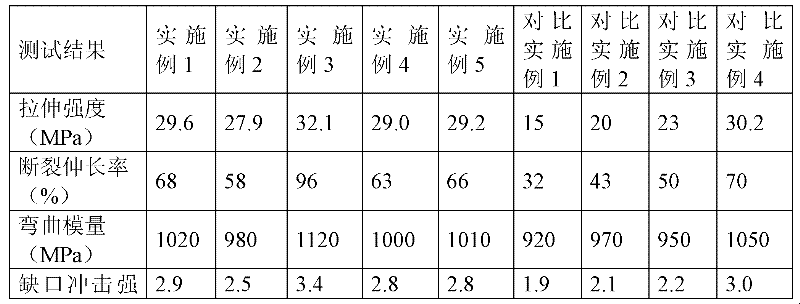

[0048] Take 50Kg of crystal waste residue, and carry out preliminary screening on the waste residue through a vibrating sieve (with a sieve hole diameter of 0.5 mm) to remove impurities and large particles. Then put the sieved crystal waste into the ball mill and grind it finely. The outlet sieve diameter of the ball mill is 400 mesh (about 33 microns). Then the finely ground crystal waste residue is dehydrated through a three-legged centrifuge, and dried in an oven until the water content is lower than 0.03%. Carry out surface coating treatment to crystal waste slag again: (1) in kneader machine, quantitative crystal waste slag is heated to 110 ℃; 20 minutes; (3) adding 1% by weight (based on the quantitative crystal waste weight) of organic silicon, and mixing for 20 minutes to obtain activated crystal waste particles. Fill the crystal waste slag into polypropylene (in), the filling amount is 10% (by weight of polypropylene): mix the weighed activated crystal waste slag and...

Embodiment 2

[0050] The treatment process of crystal waste residue is the same as in Example 1, except that the diameter of the sieve hole at the outlet of the ball mill is 300 mesh. The crystal waste slag was filled into polypropylene, and its mechanical properties were tested. The results are shown in Table 2.

Embodiment 3

[0052] The treatment process of crystal waste residue is the same as in Example 1, except that the diameter of the sieve hole at the outlet of the ball mill is 600 mesh. The crystal waste slag was filled into polypropylene, and its mechanical properties were tested. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com