Effective method for industrial fluorinion-containing waste gas treatment

A technology for waste gas treatment and fluorine ions, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of uneven density of water droplets in alkaline solutions and large gaps between water droplets, and achieve easy maintenance and management. The cost of waste gas treatment is reduced and the effect of no wearing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

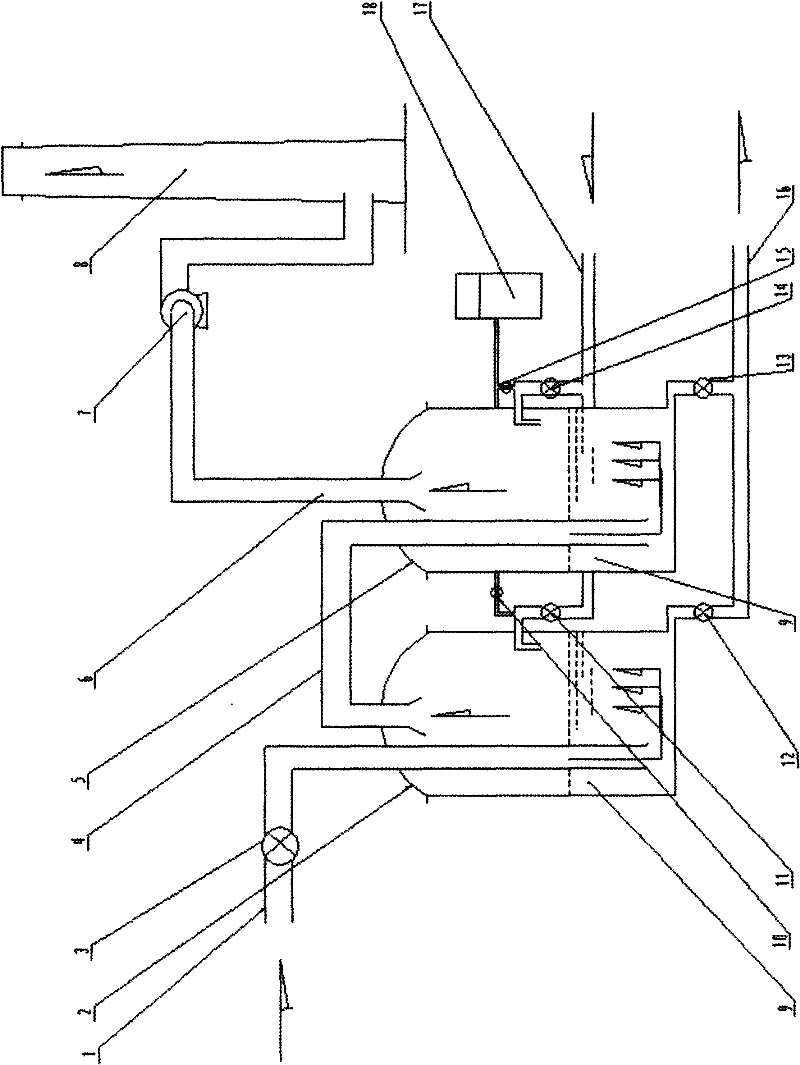

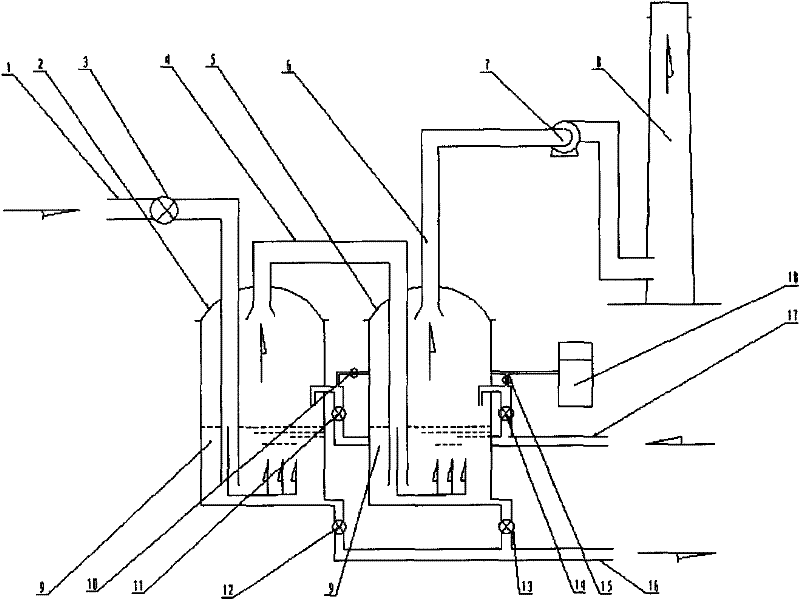

[0022] Refer to hint figure 1 Shown, the implementation process among the present invention is:

[0023] a. The industrial waste gas containing fluorine ions enters the alkaline aqueous solution 9 in the primary purification kettle 2 from the waste gas input pipe 1 through the waste gas input valve 3. Due to the negative pressure generated by the centrifugal fan 7 inlet in operation, the primary purification kettle The alkaline aqueous solution 9 in 2 is continuously boiling and bubbling, and the fluoride ions in the industrial waste gas undergo neutralization reaction with the alkaline aqueous solution 9 during the boiling and bubbling process, and then the fluorine ions are trapped and collected in the alkaline aqueous solution 9 middle.

[0024] b. The purified exhaust gas after being neutralized in the initial purification kettle 2 reaches the final purification kettle 5 through the inter-tank pipe 4, and is also carried out again in the final purification kettle 5 after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com