Solar wafer and preparation method thereof

A technology of solar wafers and wafers, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., and can solve problems such as difficulty in achieving solar conversion efficiency, doping uniformity, and precise dose control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

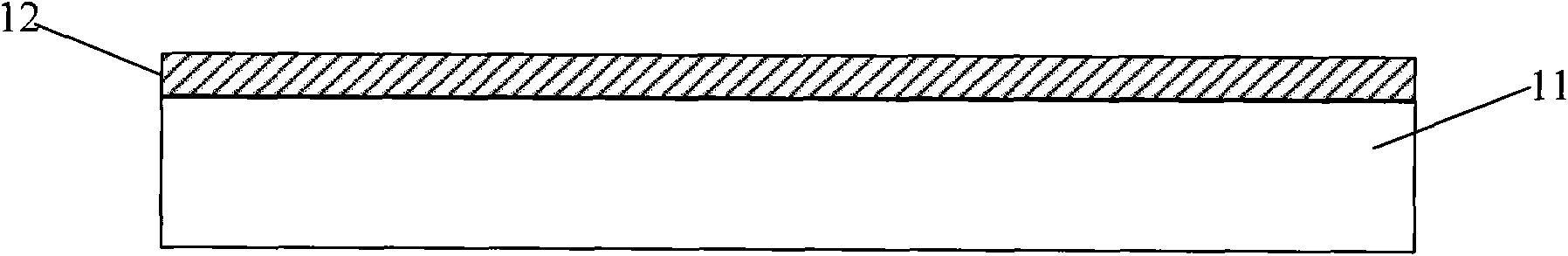

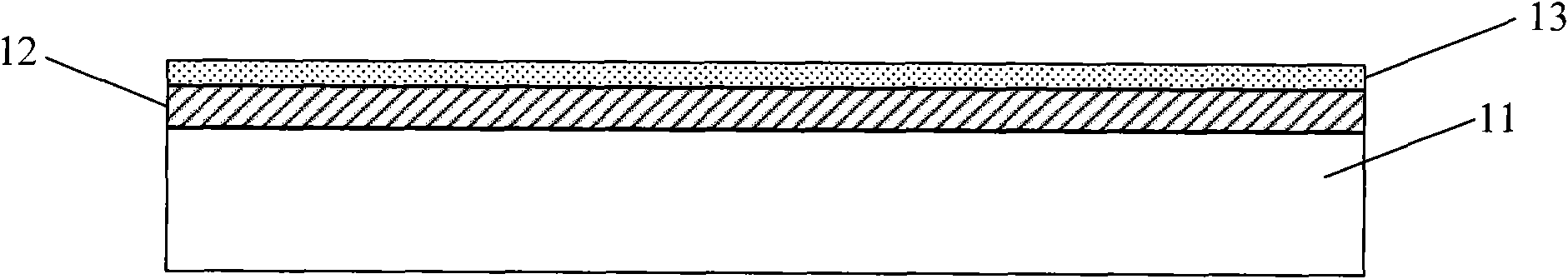

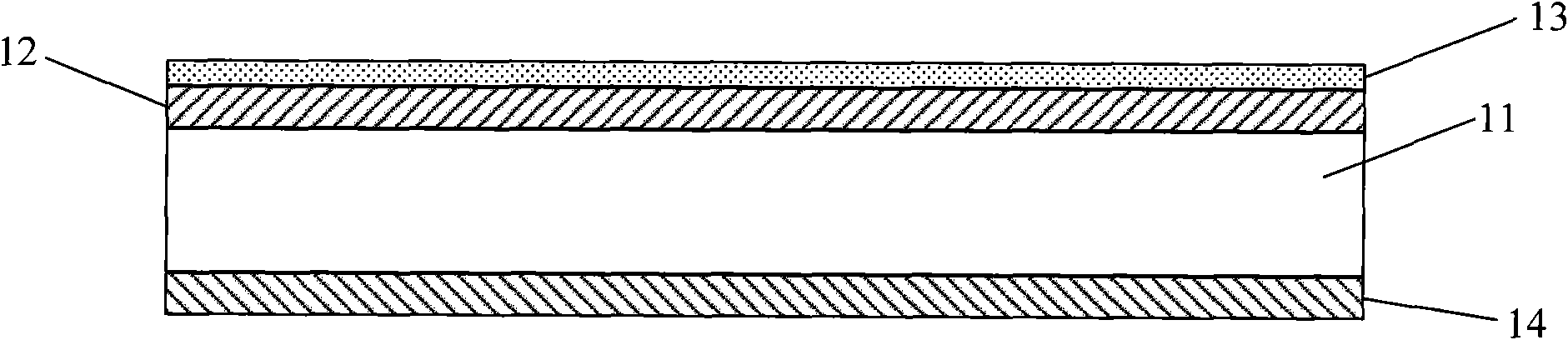

[0087] refer to Figures 1a-1g , to introduce in detail the preparation method of the solar wafer described in Embodiment 1 of the present invention.

[0088] Firstly, the wafer is cleaned, and those skilled in the art can refer to the prior art to select suitable known means for cleaning. refer to Figure 1a , step S 11 , implant P-type ions, such as boron ions, into the surface of the N-type substrate 11 wafer by means of ion implantation, so as to form a P-type doped layer 12 . Preferably, the P-type doped layer is formed by implanting boron ions with an energy of 5keV and a concentration of 5E14-1E16, and the sheet resistance of the P-type doped layer is 40-200Ω / m 2 . The P-type ions implanted by ion implantation are annealed, the annealing temperature is higher than 900°C, and the annealing time is longer than 30 seconds, so as to activate the doping impurities. In addition, those skilled in the art can also choose other annealing methods according to actual needs. te...

Embodiment 2

[0105] refer to Figures 2a-2g , introduces in detail the preparation method of the solar wafer described in Embodiment 2 of the present invention.

[0106] Firstly, the wafer is cleaned, and those skilled in the art can refer to the prior art to select suitable known means for cleaning. refer to Figure 2a , step S 21 1. Implanting P-type ions, such as boron ions, on the surface of the N-type substrate 21 wafer by ion implantation to form the P-type doped layer 22. Preferably, boron with an implantation energy of 5keV and a concentration of 5E14-1E16 can be used The ions form a P-type doped layer, and the sheet resistance of the P-type doped layer is 40-200Ω / m 2 .

[0107] refer to Figure 2b , step S 22 , forming an N+ type doped layer 23 on the back side of the N-type substrate 21 wafer, wherein phosphorus ions or arsenic ions with an energy of 30keV are implanted by ion implantation to form the N+ type doped layer, those skilled in the art can Select other ion implant...

Embodiment 3

[0121] Embodiment 3 The principle of the method for preparing a solar wafer is basically the same as that of Embodiment 2, the difference is that, with the following steps S 31 Replace step S in the second embodiment 21 : Implanting P-type ions on the surface of the N-type base wafer by means of ion implantation, and annealing the P-type ions, the annealing temperature is higher than 900°C, and the annealing time is longer than 30 seconds, to form a P-type doped layer, In addition, those skilled in the art can also select other annealing temperatures and times according to actual needs.

[0122] The structure of the solar wafer prepared in Example 3 is basically the same as in Example 2, except that the P-type doped layer on the surface of the N-type substrate is formed by annealing the P-type ions implanted by ion implantation. , wherein the annealing temperature is higher than 900°C and the annealing time is longer than 30 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com