Flexible composite counter electrode of dye-sensitized solar battery and preparation method thereof

A technology of solar cells and dye sensitization, applied in the field of solar cells, can solve the problems of flexible substrates that are not resistant to high temperature and the use of flexible conductive substrates, and achieve the effects of easy large-area preparation, high conductivity, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

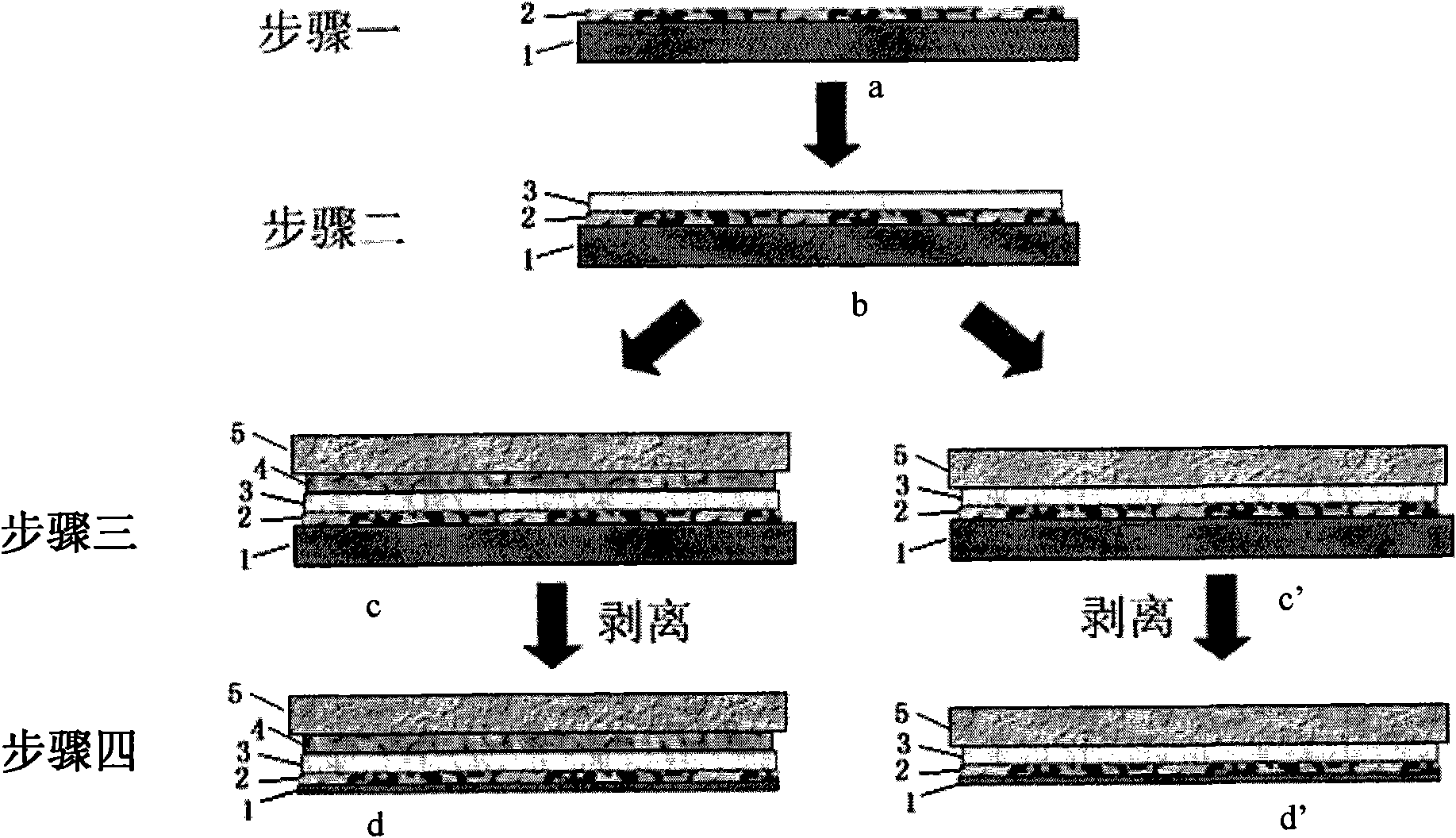

Method used

Image

Examples

example 1

[0039] A method for preparing a flexible FTO / platinum / carbon composite counter electrode, the method comprising the following steps:

[0040] Step 1): Take a graphite block as a substrate, and print a layer of H2PtCl6 solution on its surface by screen printing method. After leveling, put it in a 70°C oven to dry, take it out, and then put it in the groomer The high-temperature pyrolysis treatment was carried out in the furnace for 5 minutes, and the temperature in the muffle furnace was set to 360 ° C. After cooling down, the graphite substrate 1 with a layer of pyrolytic platinum on the surface was obtained. Particle composition, the particle diameter is between 5nm and 10nm;

[0041] Step 2): Take the graphite with pyrolytic platinum attached to the surface of step 1) as the substrate, place it on the heating platform in the ultrasonic spray pyrolysis device, and control its surface temperature to 350 ° C; prepare the prepared SnCl ethanol mixed with NH4F The solution (its ...

example 2~8

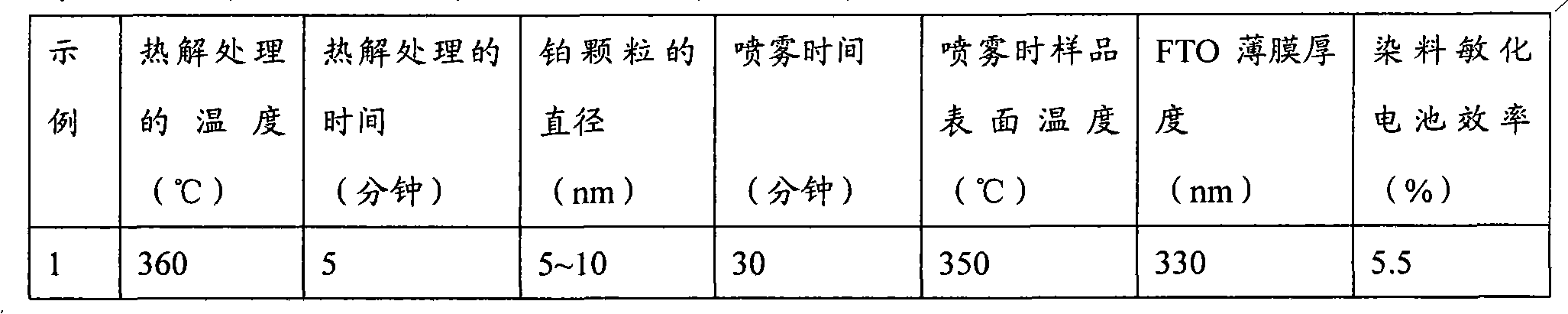

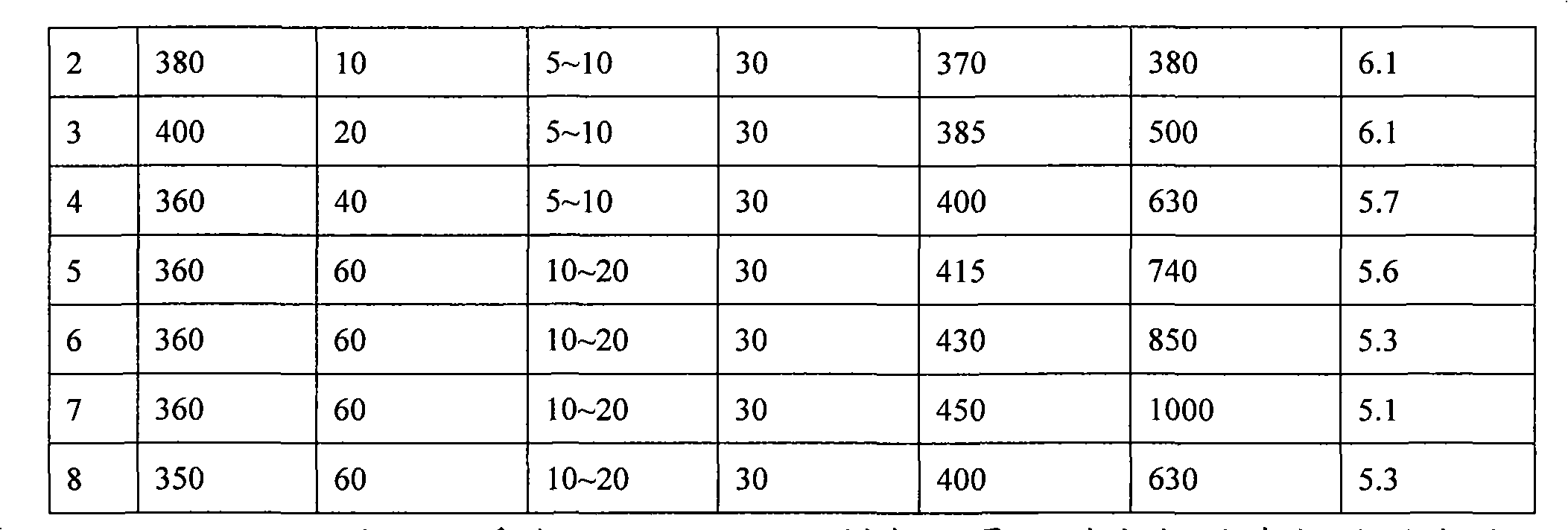

[0046] Examples 2 to 8 were prepared according to the method of Example 1, and their battery efficiency was tested, and the results are shown in Table 1 below.

[0047] Table 1. The battery efficiency of the flexible composite counter electrode obtained under different experimental conditions based on Examples 1-8

[0048]

[0049]

[0050] From the above results, it can be seen that the flexible counter electrodes prepared in Examples 2 and 3 have better cell efficiency, which can reach about 94% of the effect of pyrolytic platinum counter electrodes (PT) on traditional FTO glass.

example 9

[0052] A method for preparing a flexible FTO / platinum / carbon composite counter electrode, the method comprising the following steps:

[0053] Step 1): Take a piece of copper, attach a layer of graphite to its surface, and then scrape a layer of H on the graphite surface by scraping 2 PtCl 6 solution, put it in an oven at 70°C and take it out after drying, then put it in a muffle furnace for high-temperature pyrolysis treatment for 10 minutes, set the temperature in the muffle furnace to 400°C, and take it out after cooling to obtain graphite A layer of pyrolytic platinum on the surface of the substrate; it is measured that the layer of pyrolytic platinum is composed of platinum particles with a particle diameter of 2 nm to 10 nm;

[0054] Step 2): Take the sample with pyrolyzed platinum attached to the graphite on the surface of the copper sheet in step 1) as the substrate, put it on the heating table in the ultrasonic spray pyrolysis device, and control its surface temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com