Method for preparing functionally gradient composite coating in osmosis plating

A functional gradient and composite coating technology, which is applied in the coating, metal material coating process, electrolytic coating, etc., can solve the problems of low binding force, uneven distribution, low content of strengthening phase, etc., and achieve high binding force and easy operation. The effect of convenience, excellent mechanical properties and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Ni-SiC functionally graded composite coating was prepared on the surface of flat workpiece GH4169 nickel-based superalloy by penetration electroplating. 90vol.% gradient distribution.

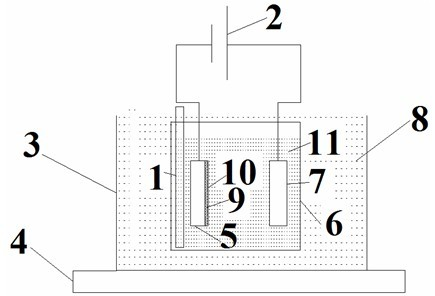

[0021] The implementation process of this embodiment is, as figure 1 and figure 2 shown.

[0022] (1) Pretreatment of the substrate surface. Sand blast or polish, degrease, etch and weakly etch the surface of GH4169 nickel-based superalloy 1;

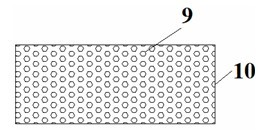

[0023] (2) Increase the distribution density of strengthening phase SiC particles 9 with an average particle size of 10 nm on the surface of the permeable membrane 10 by 0-90% by spraying or rolling, and then place the permeable membrane on the surface of the GH4169 nickel-based superalloy 1, Among them, the pore size of the permeable membrane is 6nm, the material is organic membrane polyamide, and the structure adopts plate and frame type;

[0024] (3) Place the GH4169 nickel-based superalloy 1 adhered to the permeable membrane 10 (the stre...

Embodiment 2

[0028] Preparation of Cu-TiB on 45 Steel Surface of Round Bar Workpiece by Infiltration Electroless Plating 2 Functionally graded composite coating, the thickness of the coating is 1.5mm, and the strengthening phase TiB with an average particle size of 40μm 2 The particles are distributed in a gradient of 0-90vol.% along the thickness direction of the coating.

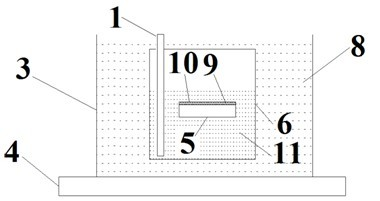

[0029] The implementation process of this embodiment is, as figure 2 and image 3 shown.

[0030] (1) Pretreatment of the substrate surface. Sand blast or polish, degrease, etch and weakly etch the surface of 45 steel 1;

[0031] (2) The reinforcement phase TiB with an average particle size of 40 μm is sprayed or rolled 2 The distribution density of particles 9 on the surface of the permeable membrane 10 is increased by 0-90%, and then the permeable membrane is placed on the surface of 45 steel 1, wherein the pore diameter of the permeable membrane 10 is 25 μm, and the material is inorganic TiO 2 Ceramic membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com