Optical high-transparency polycarbonate material and preparation method thereof

A polycarbonate and high-transparency technology, which is applied in the field of optical high-transparency polycarbonate materials and their preparation, can solve the problems of high viscosity of resin melt, poor wear resistance, and low creep.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

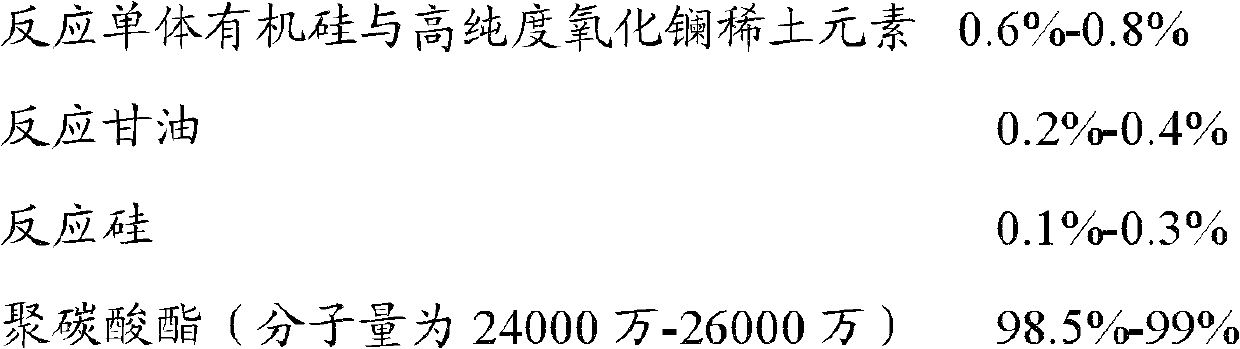

Embodiment 1

[0029] (1) First, mix 0.65 kg of macromolecular reaction monomer organosilicon with high-purity lanthanum oxide rare earth elements in a ratio of 9:1, and add them to the reaction kettle. The reaction time is 6 hours, and the reactants are controlled to react at a high temperature of 800 ° C. Into a nano-scale state, the particle size is controlled to 3nm-8nm (nanometer), so as to realize the full branching and uniform distribution of organic elements of nano-bonds and silicon-bonds, and obtain a linear optimized structure of light atoms, so that the inactive agent can be converted into a liquid active agent. agent.

[0030] (2) Then, after mixing 0.25 kg of glycerin and 0.1 kg of reactive silicon, they are added to the reaction kettle, and the liquid active agent converted into a non-active agent such as a macromolecular reaction monomer organosilicon and rare earth elements is used for a secondary reaction. Low-temperature reaction, the temperature of the reaction kettle is ...

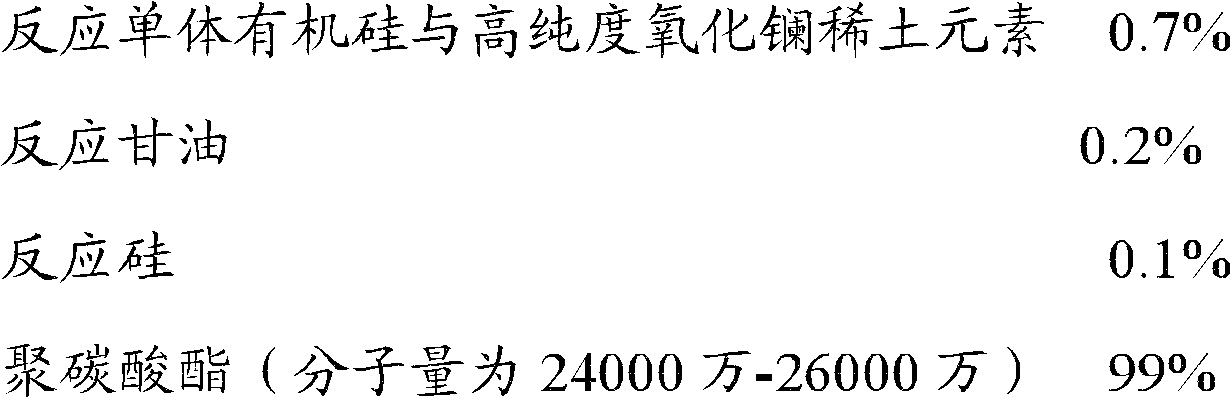

Embodiment 2

[0037] (1) First, mix 0.7kg of macromolecular reaction monomer organosilicon with high-purity lanthanum oxide rare earth element according to the ratio of 9:1, put it into the reaction kettle, and the reaction time is 6 hours, and the reactant is controlled at a high temperature of 800°C The reaction is at the nanometer level, and the particle size is controlled to 3nm-8nm, so that the organic elements of the nano-bond and the silicon-bond are fully branched and evenly distributed, and the optical atom linear optimized structure is obtained, so that it can be converted into a liquid active agent.

[0038] (2) Then, after mixing 0.2kg of glycerin and 0.1kg of reactive silicon, they are added to the reaction kettle, and the liquid active agent converted into a non-active agent such as a macromolecular reaction monomer organosilicon and rare earth elements is used for a secondary reaction. Low-temperature reaction, the temperature of the reaction kettle is set at 180°C, and a high...

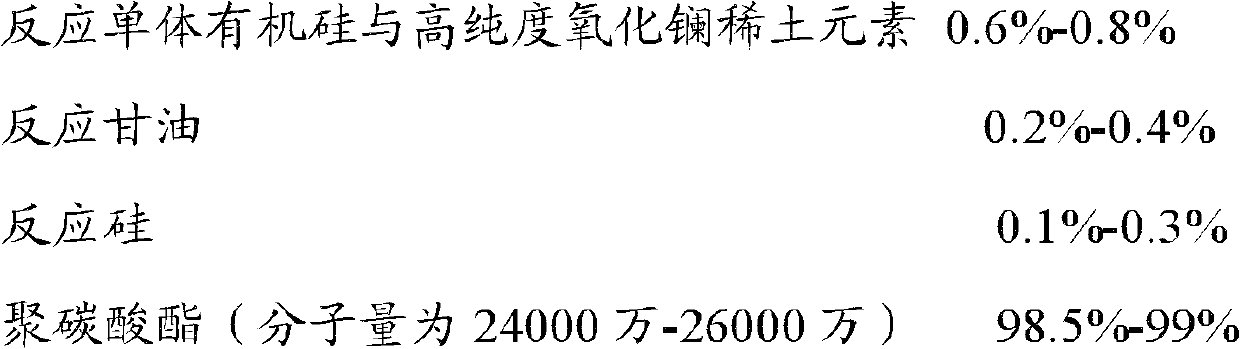

Embodiment 3

[0044] (1) First, mix 0.78 kg of macromolecular reaction monomer organosilicon with high-purity lanthanum oxide rare earth element according to the ratio of 9:1, put it into the reaction kettle, and the reaction time is 6 hours, and the reactant is controlled at a high temperature of 800 °C React into a nano-scale state, and the particle size is controlled to 3nm-8nm (nanometer), so as to realize the full branching and uniform distribution of the organic elements of the nano-bond and silicon-bond, and obtain a linear optimized structure of light atoms, so that the inactive agent can be converted into a liquid active agent.

[0045] (2) Then, after mixing 0.4kg of glycerin and 0.3kg of reactive silicon, they are added to the reaction kettle, and the liquid active agent converted into a non-active agent such as a macromolecular reaction monomer organosilicon and rare earth elements is used for a secondary reaction. Low-temperature reaction, the temperature of the reaction kettle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com