Preparation method of high-strength biodegradable plastic packaging bag

A biodegradable plastic and packaging bag technology, applied in biological packaging, sustainable packaging industry, packaging and other directions, can solve the problems of insufficient strength of plastic packaging bags, loss of self-cleaning ability of the environment, white pollution of plastic packaging bags, etc. Protective effect, improved strength and heat resistance, complete effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

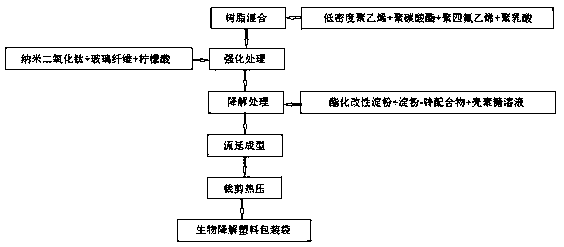

Image

Examples

Embodiment 1

[0025] A preparation method of a high-strength biodegradable plastic packaging bag, comprising the following steps:

[0026] (1) Resin mixing: put low-density polyethylene, polycarbonate, polytetrafluoroethylene and polylactic acid in the reaction kettle, add low-density polyethylene 67, polycarbonate 51, polytetrafluoroethylene 44, Polylactic acid 38, heat slowly until it is completely melted, keep stirring at 65r / min for 30 minutes, so that the raw materials are fully branched, and the added raw materials are safe and non-toxic, and will not affect the human body and the environment. After the raw materials are fully branched, the packaging will be further improved. The strength of the bag, and due to the biodegradability of polycarbonate, polytetrafluoroethylene and polylactic acid, the added grafted low-density polyethylene will also be fully degraded without causing residues, so that it will be completely degraded instead of leaving Degradation of fragments, environmental...

Embodiment 2

[0033] A preparation method of a high-strength biodegradable plastic packaging bag, comprising the following steps:

[0034](1) Resin mixing: put low-density polyethylene, polycarbonate, polytetrafluoroethylene and polylactic acid in the reaction kettle, add low-density polyethylene 68, polycarbonate 52, polytetrafluoroethylene 45, Polylactic acid 39, heat slowly until it is completely melted, keep stirring at 70r / min for 35 minutes, so that the raw materials are fully branched, and the added raw materials are safe and non-toxic, and will not affect the human body and the environment. After the raw materials are fully branched, the packaging will be further improved. The strength of the bag, and due to the biodegradability of polycarbonate, polytetrafluoroethylene and polylactic acid, the added grafted low-density polyethylene will also be fully degraded without causing residues, so that it will be completely degraded instead of leaving Degradation of fragments, environmental ...

Embodiment 3

[0041] A preparation method of a high-strength biodegradable plastic packaging bag, comprising the following steps:

[0042] (1) Resin mixing: put low-density polyethylene, polycarbonate, polytetrafluoroethylene and polylactic acid in the reaction kettle, add 69 parts by weight of low-density polyethylene, polycarbonate 53, polytetrafluoroethylene 46, Polylactic acid 40, slowly heated until completely melted, and kept stirring at 75r / min for 40 minutes to fully branch the raw materials, and the added raw materials are safe and non-toxic, and will not affect the human body and the environment. After the raw materials are fully branched, the packaging will be further improved. The strength of the bag, and due to the biodegradability of polycarbonate, polytetrafluoroethylene and polylactic acid, the added grafted low-density polyethylene will also be fully degraded without causing residues, so that it will be completely degraded instead of leaving Degradation of fragments, enviro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com