Environment-friendly flame-retardant plastic plate for building

A technology for plastic sheets and construction, which is applied in the field of environmental protection and flame retardant plastic sheets for construction, can solve the problems that the strength of plastic sheets cannot meet the hidden dangers of building sheets, personal and property safety, and cannot meet building needs, and achieves improved fluidity and combination. The effect of fastness, protection of personal and property safety, and improvement of use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

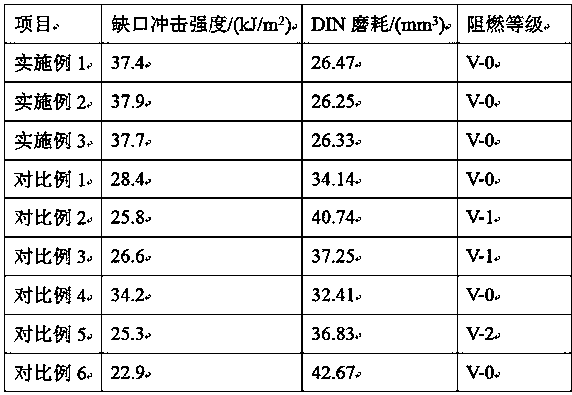

Examples

Embodiment 1

[0018] An environmentally friendly flame-retardant plastic sheet for construction, made of the following raw materials in parts by weight: phenolic resin 57, polyurethane resin 46, polytetrafluoroethylene 40, modified epoxy resin 35, polymethyl methacrylate 7, amino silicone oil 6. Glass fiber 5, nano-zinc oxide 2.4, nano-silver 1.1, graphene 0.6.

[0019] Described modified epoxy resin, epoxy resin is placed in reactor, is heated to complete melting, and insulation 20min, then adds the terpene resin of epoxy resin weight 3% in reactor, insulation and stirring 8min, can improve The weather resistance and aging resistance of epoxy resin can be improved by adding borax solution with 2% weight of epoxy resin and stirring for 30 minutes. Modified epoxy resin.

[0020] Described borax solution, mass percentage concentration is 0.5%.

[0021] A method for preparing an environmentally friendly flame-retardant building plastic plate, comprising the following steps:

[0022] (1) Put...

Embodiment 2

[0028] An environmentally friendly flame-retardant plastic sheet for construction, made of the following raw materials in parts by weight: phenolic resin 58, polyurethane resin 47, polytetrafluoroethylene 41, modified epoxy resin 36, polymethyl methacrylate 8, amino silicone oil 6.5, glass fiber 5.5, nano zinc oxide 2.5, nano silver 1.2, graphene 0.7.

[0029] Described modified epoxy resin, epoxy resin is placed in reactor, is heated to complete melting, and insulation 25min, then adds the terpene resin of epoxy resin weight 3.5% in reactor, insulation and stirring 9min, can improve The weather resistance and aging resistance of epoxy resin can be improved by adding borax solution with 2.5% epoxy resin weight and stirring for 35 minutes. Modified epoxy resin.

[0030] Described borax solution, mass percentage concentration is 0.6%.

[0031] A method for preparing an environmentally friendly flame-retardant building plastic plate, comprising the following steps:

[0032] (1...

Embodiment 3

[0038]An environmentally friendly flame-retardant plastic sheet for construction, made of the following raw materials in parts by weight: phenolic resin 59, polyurethane resin 68, polytetrafluoroethylene 42, modified epoxy resin 37, polymethyl methacrylate 9, amino silicone oil 7. Glass fiber 6, nano-zinc oxide 2.6, nano-silver 1.3, graphene 0.8.

[0039] Described modified epoxy resin, epoxy resin is placed in reactor, is heated to complete melting, and insulation 30min, then adds the terpene resin of epoxy resin weight 4% in reactor, insulation and stirring 10min, can improve The weather resistance and aging resistance of epoxy resin, adding 3% borax solution by weight of epoxy resin, and stirring for 40 minutes, can improve the impact resistance and flame retardancy of epoxy resin, which is beneficial to the cutting and granulation of the board, and obtains Modified epoxy resin.

[0040] Described borax solution, mass percentage concentration is 0.7%.

[0041] A method fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com