Preparation method of N-2-hydroxypropyl trimethyl ammonium chloride chitosan/ N,O-carboxymethyl chitosan naonparticle

A technology of hydroxypropyl trimethyl ammonium chloride and carboxymethyl chitosan is applied in the field of preparation of chitosan nanoparticles, and can solve the problems of complicated operation, difficult cleaning of cross-linking agent or emulsifier, and harsh process conditions. and other problems, to achieve the effect of simple preparation process, relatively low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

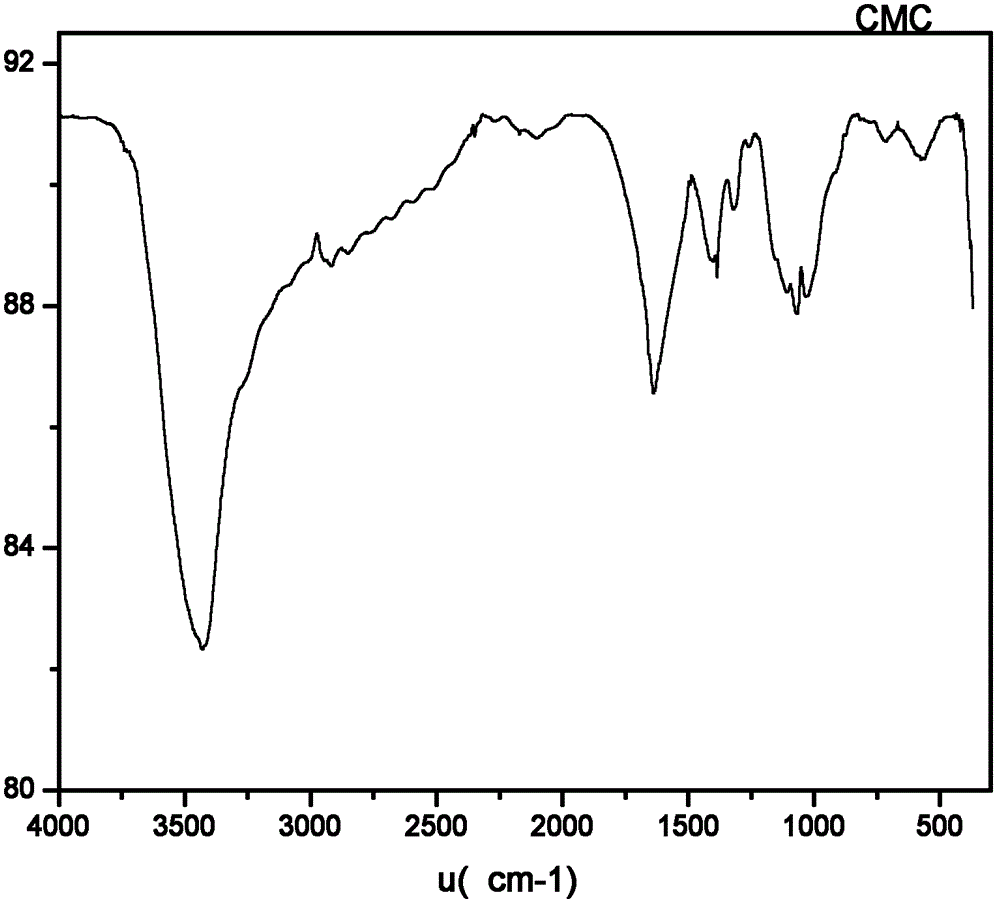

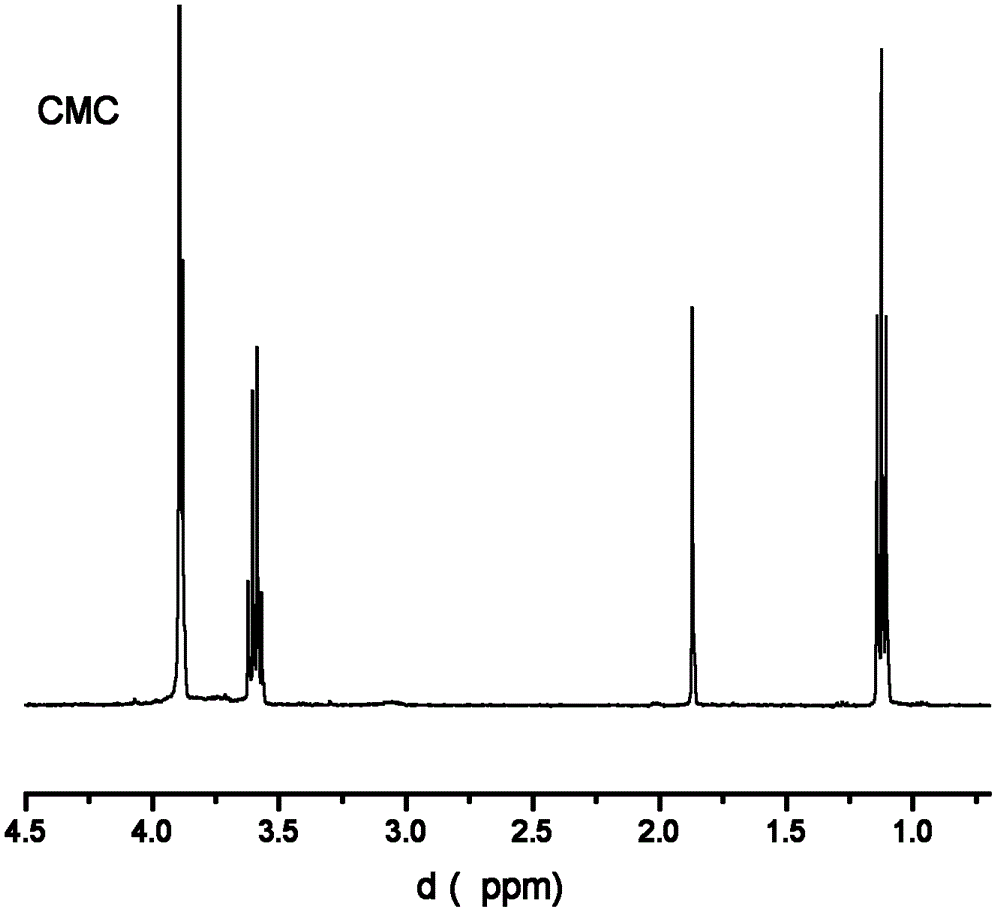

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: present embodiment N-2-hydroxypropyltrimethylammonium chloride chitosan / N, the preparation method of O-carboxymethyl chitosan nanoparticle, realizes according to the following steps:

[0019] 1. Put 5g of powdered chitosan in a 250mL three-neck flask, add 40mL of isopropanol and stir, soak for 1 to 12 hours, then add 60mL of NaOH solution with a concentration of 10 to 40mol / L, stir well and soak for 2 to 24 hours, Obtain alkalized chitosan;

[0020] 2. Heat 20g of chloroacetic acid in a water bath and dissolve it in 10mL of isopropanol, add it to the alkalized chitosan in 5 times under stirring, with an interval of 10 minutes each time, and then react at 40-80°C for 2-8 hours. Prepare the carboxymethyl chitosan mixture, then add 20mL of distilled water, adjust the pH to 7.0 with hydrochloric acid with a volume concentration of 1%, then suction filter with a Buchner funnel, add 4 times the amount of absolute ethanol to the filtrate to fully preci...

Embodiment 1

[0032] N-2-hydroxypropyltrimethylammonium chloride chitosan / N, the preparation method of O-carboxymethyl chitosan nanoparticle, realizes according to the following steps:

[0033] 1. Put 5g of powdered chitosan in a 250mL three-neck flask, add 40mL of isopropanol and stir, soak for 2 hours, add 60mL of NaOH solution with a concentration of 30mol / L, stir well and soak for 2 hours to obtain alkalized chitosan ;

[0034] 2. Heat 20g of chloroacetic acid in a water bath and dissolve it in 10mL of isopropanol, add it to the alkalized chitosan in 5 times under stirring, with an interval of 10min each time, and then react at 70°C for 8h to obtain carboxymethyl base chitosan mixture, then add 20mL of distilled water, adjust the pH to 7.0 with hydrochloric acid with a volume concentration of 1%, and then filter with Buchner funnel, add 4 times the amount of absolute ethanol to the filtrate to fully precipitate, filter, and then use Wash with ethanol and absolute ethanol with a volume ...

specific Embodiment approach 2

[0041] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, after soaking for 4 hours, add 60 mL of NaOH solution with a concentration of 20 mol / L, stir well and then soak for 5 hours. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com