Etching liquid

An etching solution and etching technology, applied in the direction of surface etching composition, chemical instruments and methods, electrical components, etc., can solve the problems of etching rate influence, effective utilization of resources and other problems, and achieve small composition changes and low exchange frequency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1

[0072] Examples 1 to 3 and Comparative Example 1: Evaporation test

[0073] 50% by mass of hydrofluoric acid (A), 40% by mass of ammonium fluoride (B) (containing 0.07% by mass of HF), and the salt (C) obtained from the acids and salts shown in Table 1 were mixed at a predetermined concentration And water (D) to prepare 400 g of etching solution. The HF concentration was adjusted by supplementing the insufficient amount of hydrofluoric acid contained in the added ammonium fluoride (B) with 50% by mass of hydrofluoric acid (A). In addition, among the acids and bases used in the preparation of the salt (C), acetic acid was used at a concentration of 100% by mass, and CH 3 CH 2 NH 2 Use 70% by mass aqueous solution, (CH 3 ) 3 A 25% by mass aqueous solution was used for NOH.

[0074] [Weight measurement of etching solution]

[0075] Store half of the prepared etching solution in a closed container. The remaining half is put into a cylindrical container with a diameter of 8 cm, and th...

Embodiment 4~5

[0088] Examples 4 to 5 and Reference Example 1: Evaporation test

[0089] The NH in the etching solution 4 F concentration is adjusted to 2% by mass, and NH 4 The concentration of F, the type of salt (C), and the amount of salt (C) added were adjusted as shown in Table 3. Except that, the same as Examples 1 to 3 and Comparative Example 1 were carried out to prepare Examples 4 to 5 and Reference Examples 1 of the etching solution. Among them, acetic acid and CH 3 CH 2 NH 2 The same substances as in Examples 1 to 3 and Comparative Example 1 were used, and a 44% by mass aqueous solution of choline was used.

[0090] Table 3 shows the compositions of Examples 4 to 5 and Reference Example 1, and Table 4 shows the results.

[0091] [table 3]

[0092]

[0093] [Table 4]

[0094]

[0095] Even in the NH 4 When the F concentration is adjusted to 2% by mass, the addition of a salt derived from acetic acid and tetramethylammonium hydroxide, and a salt derived from acetic acid and choline can al...

Embodiment 6~7 and comparative example 2

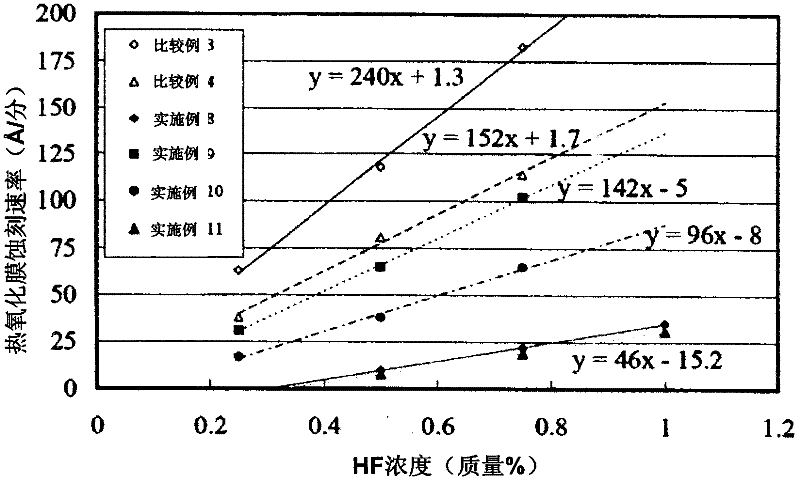

[0096] Examples 6-7 and Comparative Example 2: Water dilution test

[0097] By the same chemical liquid preparation method as shown in the chemical liquid evaporation test, 1000 g of each chemical liquid was prepared, and 200 g of the chemical liquid was prepared by mixing the predetermined amount shown in Table 5 with water, and the etching rate at 25°C was measured.

[0098] [Measurement method of etching rate]

[0099] Adjust the temperature of the etching solution stored in an airtight container to 25°C, and immerse a 1.5cm×1.2cm thermal oxide film (thin film) in each chemical solution for 5 minutes after measuring the initial film thickness, and then wash it off with water After the chemical solution was dried with nitrogen, the thickness of each diaphragm was measured. Then, the difference in film thickness before and after immersion was used as the etching amount, and the etching amount was divided by the etching time as the etching rate.

[0100] Table 5 shows the compositio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com