Method for extracting taxol simply, conveniently and efficiently

A high-efficiency technology for paclitaxel, applied in the production of bulk chemicals, organic chemistry, etc., can solve the problems of low extraction rate of paclitaxel, unsuitable for large-scale industrial production, etc., and achieve the effects of improving extraction and purification steps, reducing losses and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

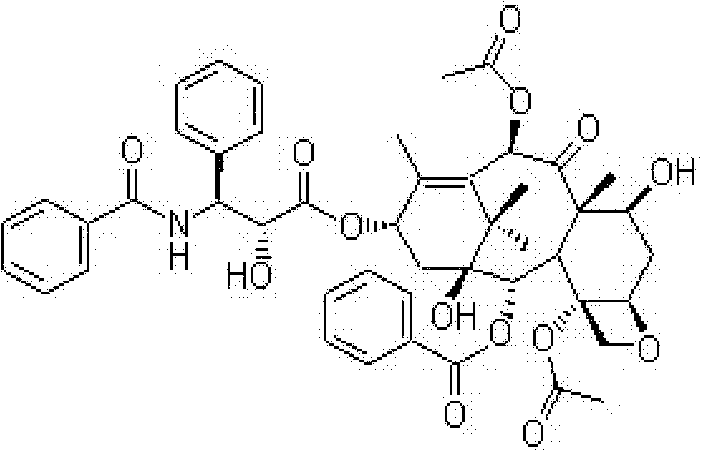

Image

Examples

Embodiment 1

[0019] (1) Grind 1000g of dried yew medicinal materials into coarse powder, pass through a 20-mesh sieve, and use supercritical CO 2 Extraction method to remove fat-soluble impurities, extraction temperature: 40°C, extraction pressure: 25MPa, extraction time 3h, without entrainer;

[0020] (2) Add 8 g of cellulase to the medicinal dregs, add 8 L of water, and hydrolyze at 70° C. for 30 hours;

[0021] (3) filter, after the dregs of the medicine are dried, extract with 5 times amount of ethanol, the extraction method adopts the percolation method: put the above-mentioned medicine dregs into the percolation cylinder, use 95% ethanol as the solvent, first soak for 12 hours, and then Percolate starts to flow out from the lower port, and new solvent is continuously added to the upper port of the percolation cylinder until there is no more paclitaxel, and the solvent always maintains a concentration difference;

[0022] (4) Filtrate, recover ethanol under reduced pressure at 35°C u...

Embodiment 2

[0026] (1) Grind 1000g of dried yew medicinal materials into coarse powder, pass through a 20-mesh sieve, and use supercritical CO 2 Extraction method to remove fat-soluble impurities, extraction temperature: 50°C, extraction pressure: 30MPa, extraction time 2h, without entrainer;

[0027] (2) Add 10 g of cellulase to the dregs, add 10 L of water, and hydrolyze at 65°C for 25 hours;

[0028] (3) filter, after dregs are dried, extract with 8.5 times amount of ethanol, the extraction method adopts the percolation method: put the above dregs into the percolation cylinder, use 95% ethanol as solvent, soak for 30 hours at first, then by Percolate starts to flow out from the lower port, and new solvent is continuously added to the upper port of the percolation cylinder until there is no more paclitaxel, and the solvent always maintains a concentration difference;

[0029] (4) Filtrate, recover ethanol under reduced pressure at 47°C until the residue has no alcohol smell;

[0030] ...

Embodiment 3

[0033] (1) Grind 1000g of dried yew medicinal materials into coarse powder, pass through a 20-mesh sieve, and use supercritical CO 2 Extraction method to remove fat-soluble impurities, extraction temperature: 60°C, extraction pressure: 35MPa, extraction time 1h, without entrainer;

[0034] (2) Add 12 g of cellulase to the medicinal dregs, add 12 L of water, and hydrolyze at 60° C. for 20 hours;

[0035] (3) Filtration, after the medicinal residues are dried, extract with 12 times the amount of ethanol, percolation method: put the above medicinal residues into the percolation cylinder, use 95% ethanol as solvent, first soak for 48 hours, and then start to flow out from the lower mouth For the percolation solution, new solvents are continuously added to the top of the percolation cylinder until there is no more paclitaxel, and the concentration difference of the solvents is always maintained.

[0036] (4) Filtrate, recover ethanol under reduced pressure at 60°C until the residu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com