Silicon-based multi-layer cavity filter

A cavity filter and silicon-based technology, applied in waveguide devices, electrical components, circuits, etc., can solve the problems of inability to meet the miniaturization requirements of the system, the processing accuracy cannot be satisfied, and the difficulty of system integration to achieve small radiation loss , Improve device performance, easy to realize the effect of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

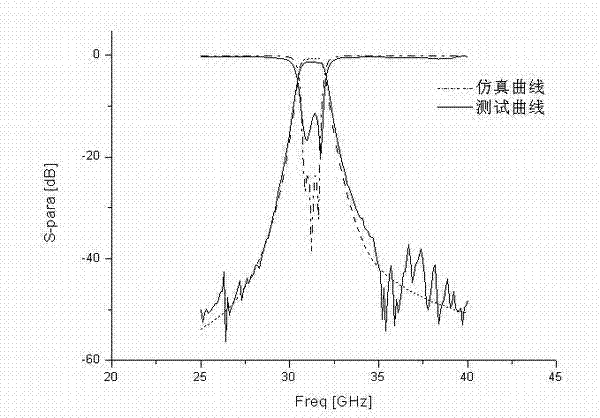

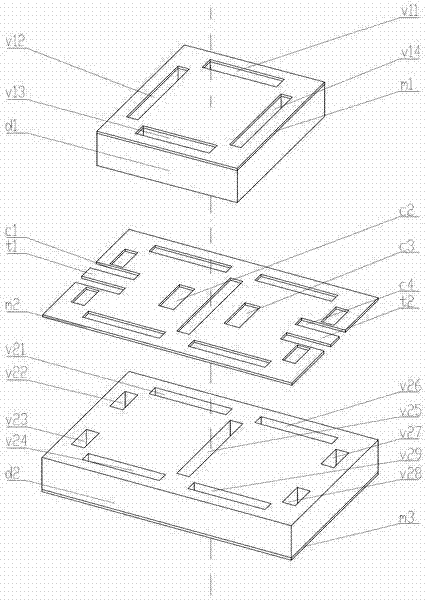

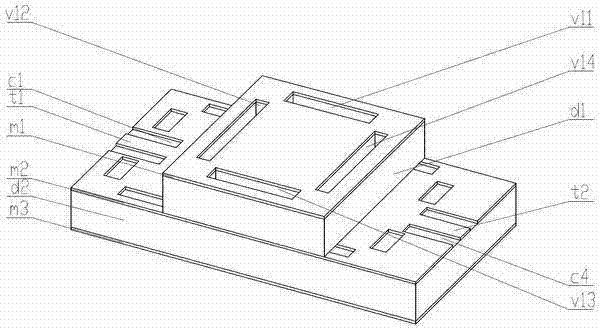

[0022] Depend on figure 2 with image 3 It can be known from the shown embodiment 1: a silicon-based multilayer cavity filter, the filter is composed of an upper dielectric layer d1 and a lower dielectric layer d2 made of high-resistance silicon, and the upper dielectric layer d1 is provided with a filter that satisfies the resonance condition The first to fourth through holes v11, v12, v13, and v14 formed by silicon micromachining technology, and the fifth to thirteenth through holes formed by silicon micromachining technology that meet the resonance conditions are arranged on the lower dielectric layer d2. Holes v21, v22, v23, ..., v29, the shape of the through hole is rectangular (or square, circular, long); on the inner wall of the through hole, there is an inner wall formed by silicon micromachining technology. Metal layer; an intermediate metal layer m2 is provided between the upper dielectric layer d1 and the lower dielectric layer d2, and the intermediate metal layer...

Embodiment 2

[0025] Depend on Figure 4 with Figure 5 The shown embodiment 2 shows: a silicon-based multilayer cavity filter, the filter is composed of a top dielectric layer D1, a second dielectric layer D2 and a bottom dielectric layer D3 using high-resistance silicon, and the first dielectric layer D1 The first to ninth through holes V11, V12, ..., V19 are provided on the top, the tenth to sixteenth through holes V21, V22, ..., V27 are provided on the second dielectric layer D2, and the third dielectric layer D3 is provided with seventeenth to twenty-third through holes V31, V32, ..., V37, the shape of the through holes is rectangular (or square, circular, long strip), the inner wall of the through hole The inner wall metal layer is provided by silicon micromachining technology, and the first intermediate metal layer M2 is provided between the top dielectric layer D1 and the second dielectric layer D2. The first intermediate metal layer M2 is provided on the silicon micromachining tec...

Embodiment 3

[0029] The difference from Example 2 is that the first intermediate metal layer is composed of an upper part and a lower part, and the upper part is provided on the lower surface of the upper dielectric layer adjacent to the first intermediate metal layer through silicon micromachining technology On the top, the lower part is provided on the upper surface of the lower dielectric layer adjacent to the first intermediate metal layer through silicon micromachining technology; the upper part and the lower part are provided with the same shape (or different shape) at the same position ) interstage coupling window. The upper part and the lower part of the first intermediate metal layer are respectively connected to form the first intermediate metal layer through a bonding process in silicon micromachining technology.

[0030] In the present invention, the shape of the through hole on the dielectric layer can be rectangular, square, circular or long; the metal layer in contact with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com