Refrigeration heating system semi-physical simulation experimental method

A semi-physical simulation and test method technology, applied in the field of improvement of refrigeration and heating system simulation test methods, can solve the problems of long production cycle of system accessories, huge system, large compensation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

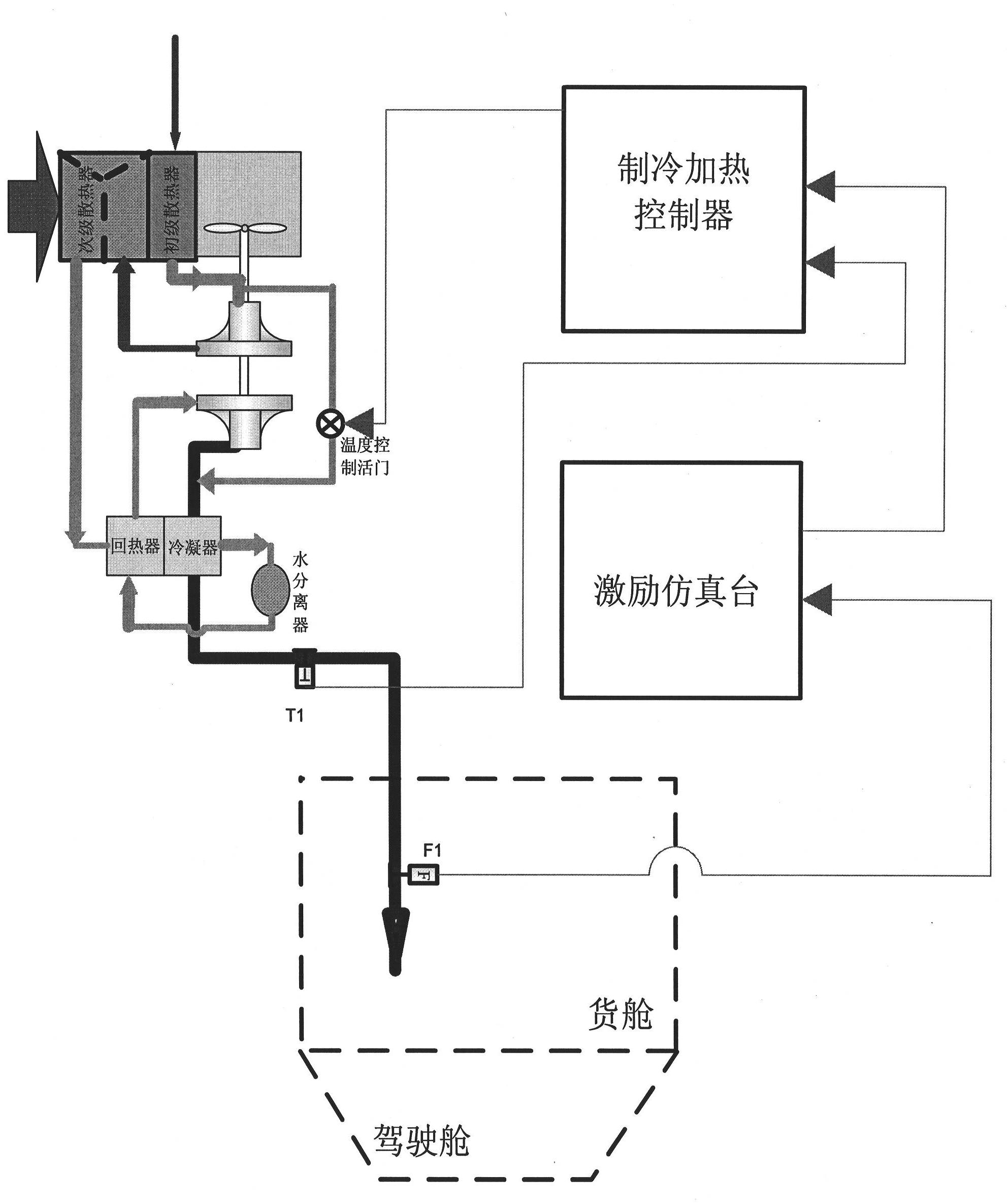

Embodiment 1

[0082] figure 1 Among them, the working principle of the refrigeration component is: the high-temperature and high-pressure gas drawn from the engine is cooled by the ram air in the primary heat exchanger, enters the compressor and is compressed to a higher pressure and temperature, and then enters the secondary heat exchanger for cooling. The supply air is cooled by cool air from the water separator as it passes through the regenerator. In the condenser, the moisture in the air is condensed from a vapor state to a liquid state under high pressure. After passing through the water separator, the air containing a small amount of condensed water droplets passes through the cold end of the regenerator to cool the air supply on the hot side and prevent the turbine from icing. The air supply is expanded and cooled by the turbine, and the shaft power generated during the expansion drives the compressor and the fan to rotate, and the heat energy is converted into mechanical energy, so...

Embodiment 2

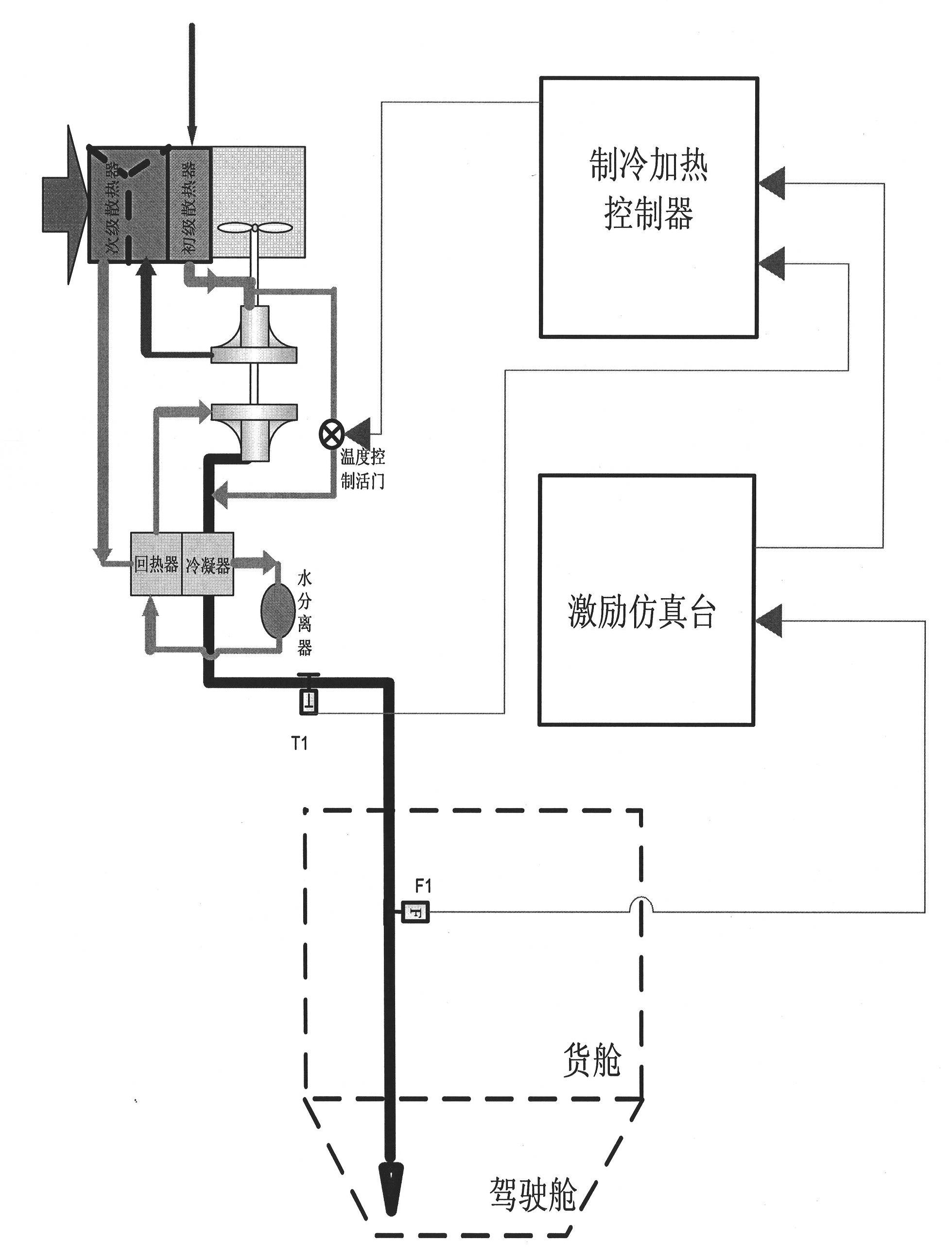

[0127] The cooling and heating assembly, excitation simulation platform, and cooling and heating controller in Embodiment 2 are the same as those in Embodiment 1.

[0128] experiment procedure:

[0129] First, as shown in the figure above, connect the above-mentioned cooling and heating controller, a set of real cooling components and the excitation simulation platform through wires;

[0130] The cooling and heating controller is connected with the temperature control valve in the real cooling component and the outlet temperature sensor of the cooling component through wires, and the cooling and heating controller controls the temperature control valve through the 28V / PWM output interface; at the same time, the cooling and heating controller and the excitation simulation platform are connected through wires Connection, the cooling and heating controller receives the simulation signal of the excitation simulation platform through the PT1000 resistance three-wire acquisition int...

Embodiment 3

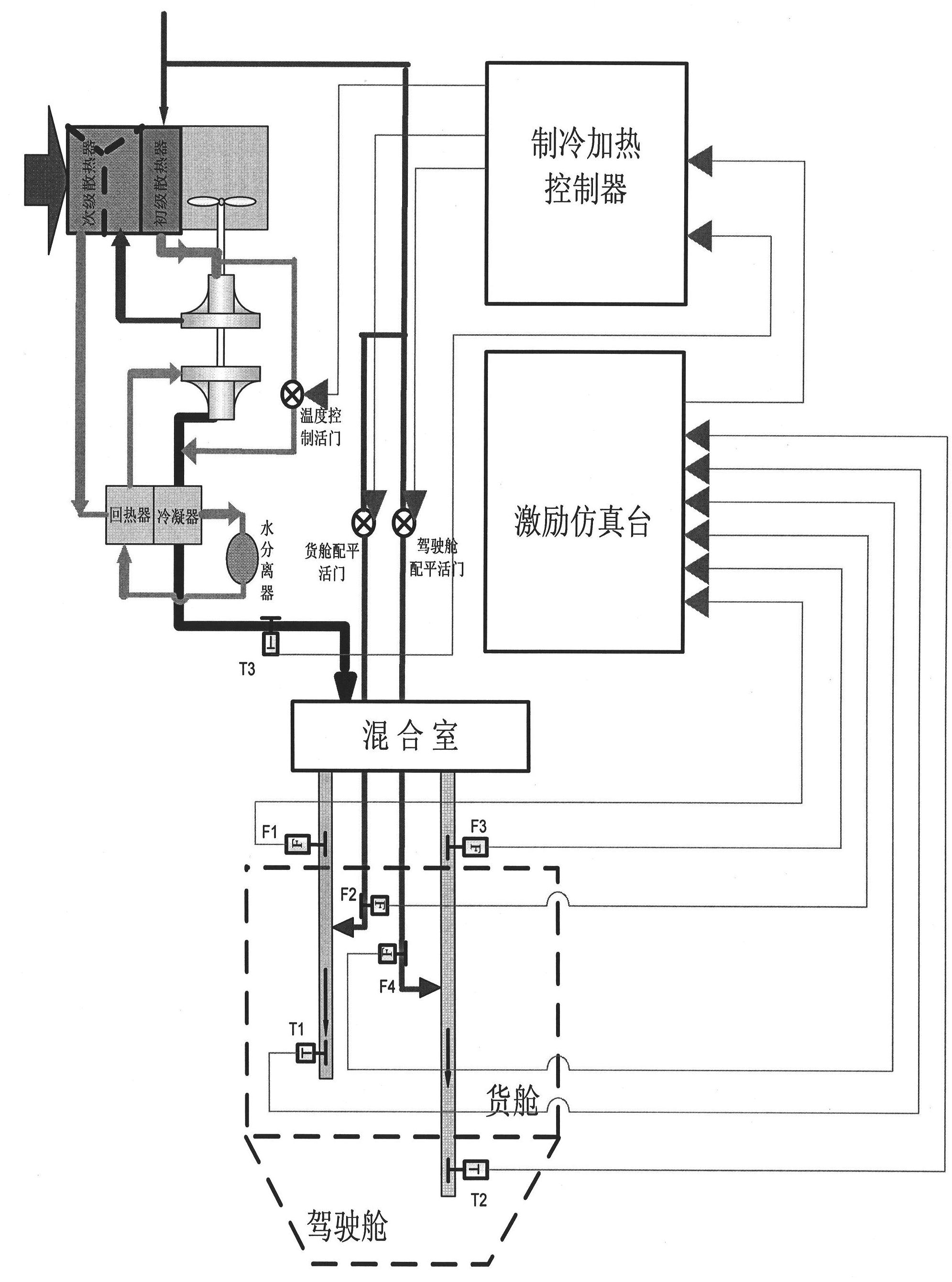

[0144] The cooling and heating assembly in Example 3 is based on the cooling and heating assembly in Example 1, adding a set of trim system, a mixing chamber, cockpit pipeline temperature sensor (T2), cockpit pipeline flow sensor (F3), cargo compartment Pipeline temperature sensor (T1), cargo tank pipeline flow sensor (F1). The trim system is composed of cockpit trim valve, cargo compartment trim valve, cockpit trim flow sensor (F3), cargo compartment trim flow sensor (F2) and some conduits.

[0145] The excitation simulation platform and cooling and heating controllers in Embodiment 2 are the same as those in Embodiment 1.

[0146] experiment procedure:

[0147] First, as shown in the figure above, connect the above-mentioned cooling and heating controller, a set of real cooling components and the excitation simulation platform through wires;

[0148] The cooling and heating controller is connected with the temperature control valve in the real cooling assembly, the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com