Water-based polyurethane elastomer emulsion, and preparation method and application thereof

A water-based polyurethane and elastomer technology, applied in the field of water-based polyurethane elastomer emulsions, can solve the problems of poor strength and high modulus, and achieve excellent mechanical properties, good hand feel, and easy penetration or removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

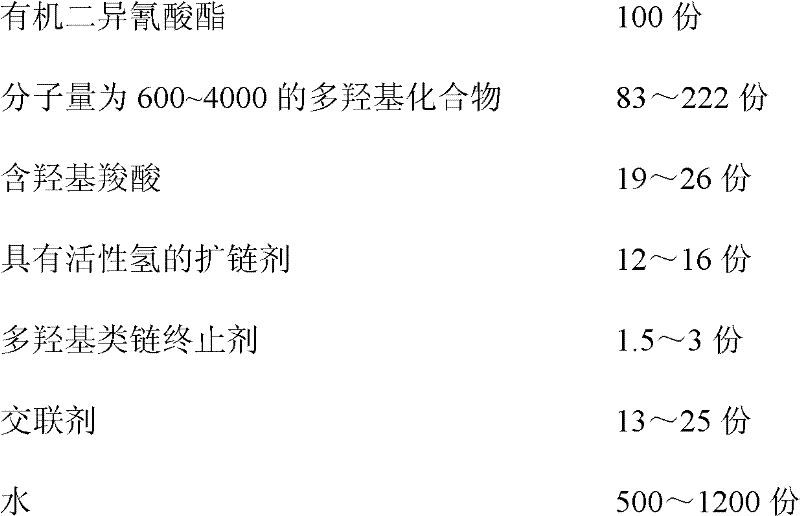

Method used

Image

Examples

Embodiment 1

[0042] 150.6g of polyoxypropylene diol PPG-2000 (molecular weight 2000) was vacuum dehydrated at 120°C and -0.96MPa for 2h, 67.87g of isophorone diisocyanate, 17.21g of dimethylol propionic acid and 0.136g of dibutyl Tin dilaurate was reacted at 80°C for 2 hours, and 8.44 g of 1,4-butanediol was added for chain extension. The measured NCO% was 0.27 (theoretical value was 0.28), and 1.72 g of diethanolamine was added until the NCO% was 0, and the temperature was lowered. To 55°C, add 10.39g triethylamine for neutralization for 1h, add 14.84g BL3175 (a product of Bayer Company, a non-aqueous blocked polyisocyanate with a solid content of 75wt%, wherein the blocked NCO content is 8.33wt%), 620.1 g of deionized water was added under stirring, and stirred for 3 hours to obtain an aqueous polyurethane emulsion with a solid content of 30 wt%.

[0043]The mold is immersed in the coagulant liquid, and the coagulant solution is CaCl with a mass fraction of 12 wt%. 2 and 3wt% Ca(NO 3 )...

Embodiment 2

[0045] 200.67g of polyoxypropylene diol PPG-1000 was vacuum dehydrated at 120°C and -0.96MPa for 2h, 126.63g of isophorone diisocyanate, 24.04g of dimethylol propionic acid and 0.1266g of dibutyltin dilaurate React at 75°C for 3 hours, add 16.13g of 1,4-butanediol for chain extension, the measured NCO% is 0.24 (theoretical value is 0.25), add 2.31g of diethanolamine until the NCO% is 0, cool down to 50°C, Add 16.32g triethylamine and neutralize 1h, add 8.93g BI7963 (product of Bassington Chemical Company, a kind of non-aqueous blocked polyisocyanate, solid content 70wt%, wherein blocked NCO content is 6.16wt%), under stirring Add a mixture of 86.12g BI7987 (a water-based blocked polyisocyanate with a solid content of 40wt% and a blocked NCO content of 1.8wt%) and 733.9g deionized water, and stir for 3 hours to obtain a water-based polyisocyanate with a solid content of 35wt%. polyurethane emulsion.

[0046] The product preparation method is the same as that in Example 1, exce...

Embodiment 3

[0048] 160.4g of polyoxypropylene glycol PPG-2000 and 20.05g of polypropylene glycol PPG-1000 were vacuum dehydrated at 120°C and -0.96MPa for 2h, 96.80g of isophorone diisocyanate, 25.39g of dimethylol propionic acid and 0.1452 g of stannous octoate was reacted at 80°C for 2 hours, 12.23g of 1,4-butanediol was added for chain extension, and the NCO% was measured to be 0.24 (theoretical value was 0.25), and 2.54g of trimethylolpropane was added to reach the NCO% to 0, lower the temperature to 55°C, add 16.28g of triethylamine for neutralization for 1 hour, add 31.29g of BI7963, add 425.2g of deionized water while stirring, and stir for 3 hours to obtain an aqueous polyurethane emulsion with a solid content of 45wt%.

[0049] The product preparation method is the same as that in Example 1, except that it is finally dried at 125° C. for 25 minutes, and then demolded. The properties of the products obtained are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com