Method and device for soldering metal parts and components by adopting high-frequency induction brazing

A high-frequency induction brazing and welding method technology, applied in the direction of electric heating devices, auxiliary devices, welding media, etc., can solve the problems of weld seam corrosion, easy to reduce sealing, reduce weld strength and conductivity, etc., to prevent welding Seam corrosion, increased productivity, and shortened welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

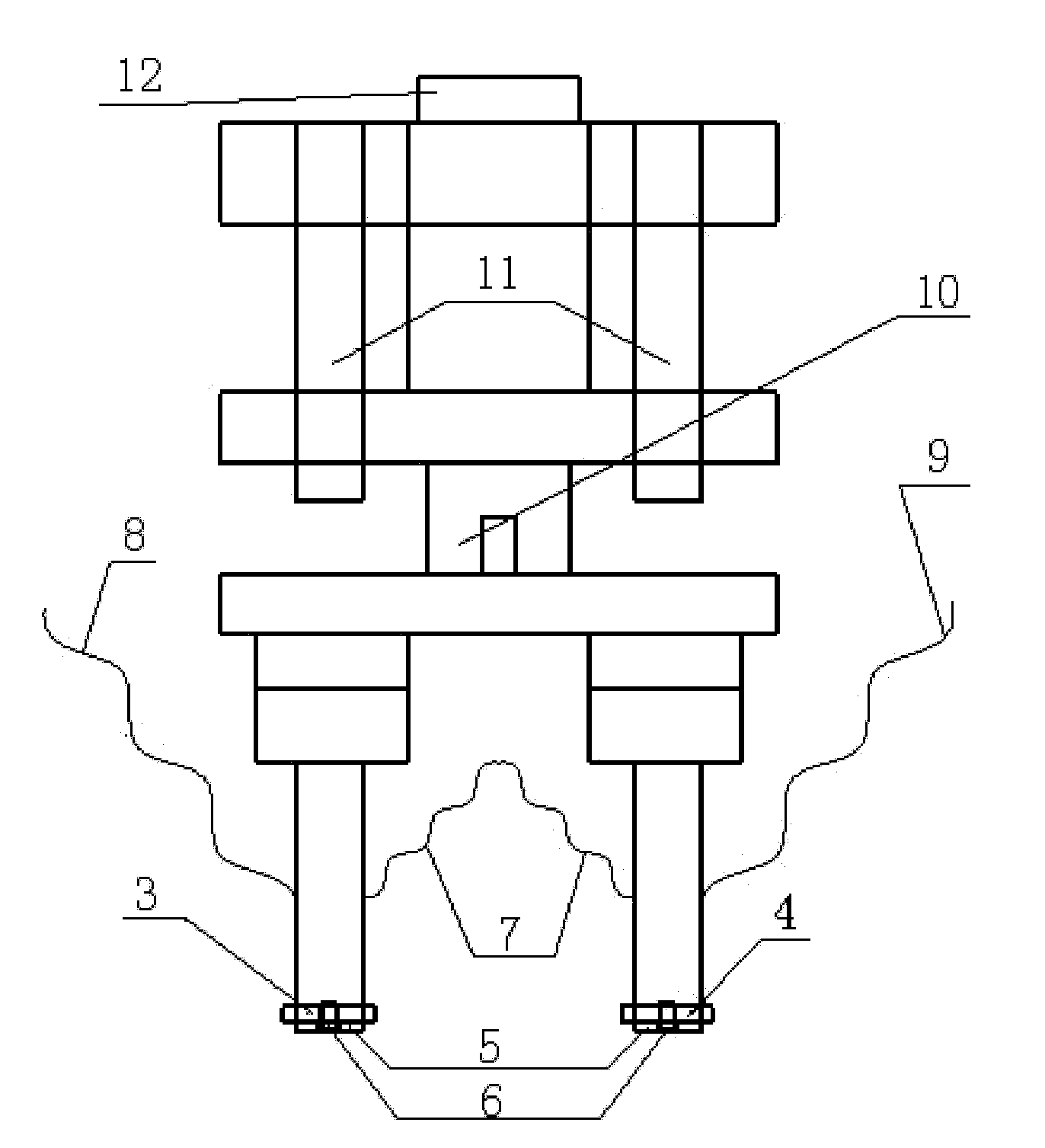

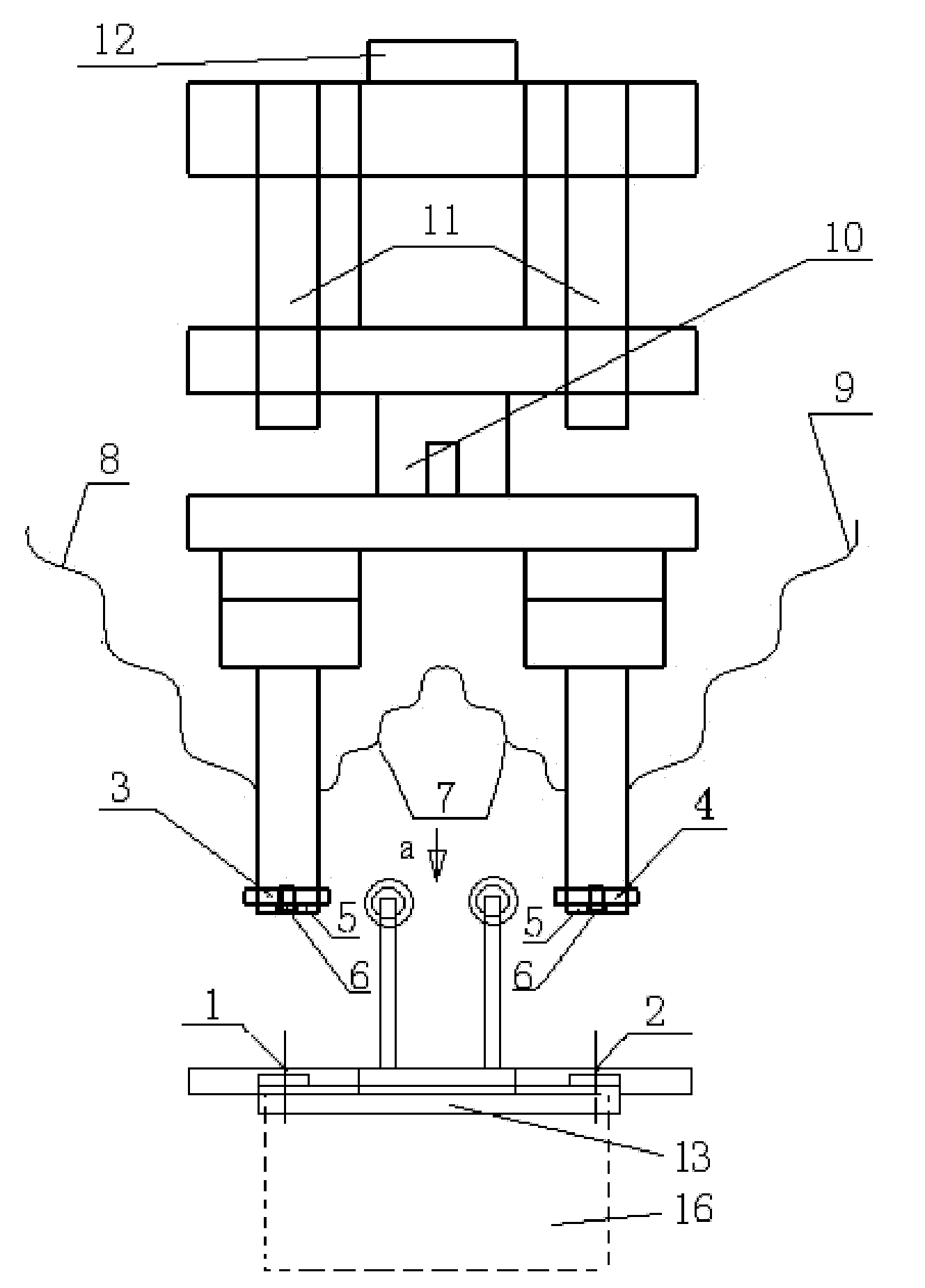

[0095] High-frequency AC welding between dissimilar metals with different thicknesses:

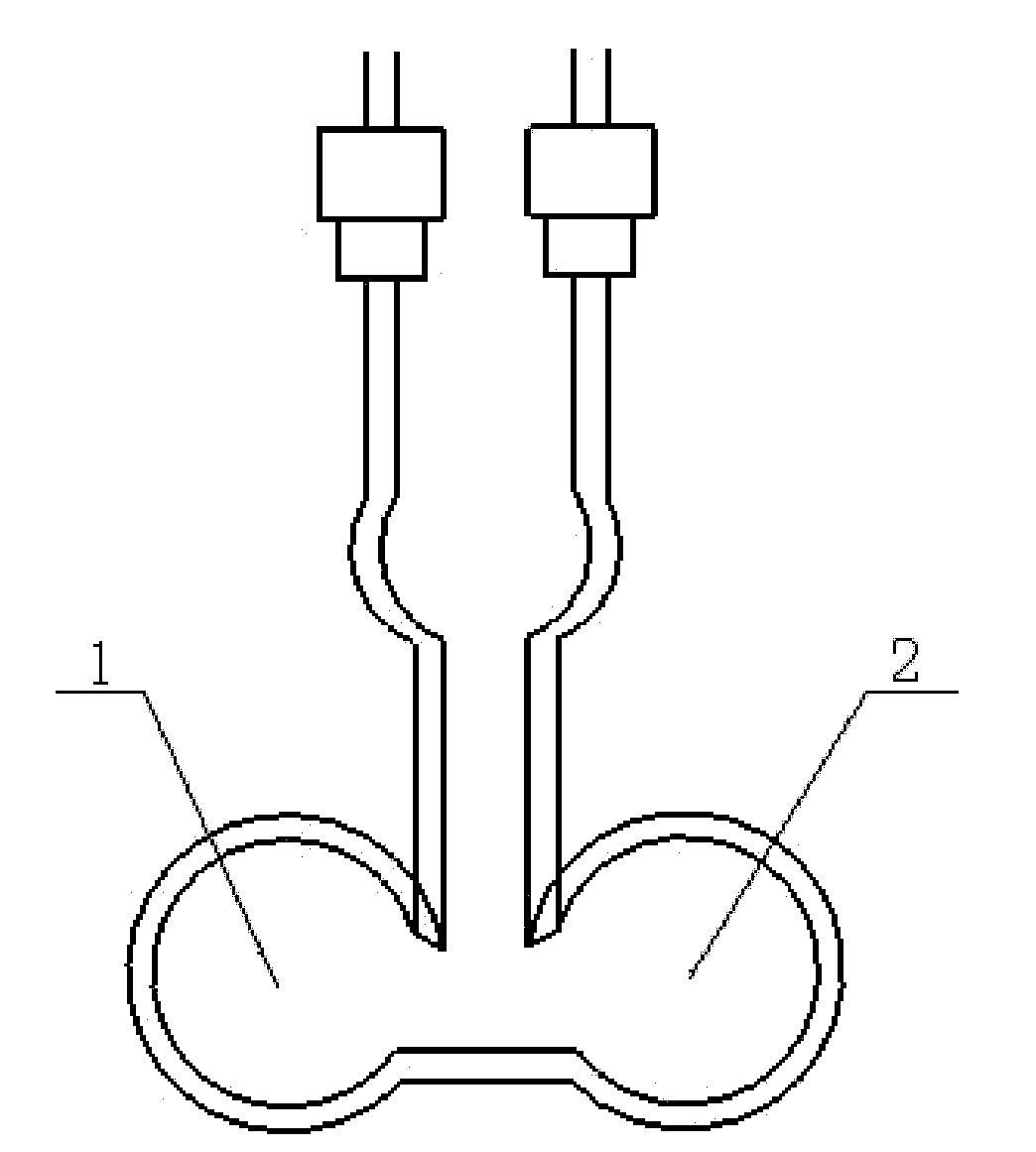

[0096] Such as Figure 4 , the first weldment in embodiment 1 is a U-shaped contact bridge 15, which is an iron copper plating groove; Each end is welded with a silver contact 14;

[0097] The first is to select the device:

[0098] Select the device power, where the theoretical power is:

[0099] Power (KW) = weldment weight (Kg) × temperature (°C) × specific heat capacity {J / (kg)°C} / 3600 (seconds),

[0100] The weight of the iron copper plating tank is 0.033Kg, the weight of two silver contacts is 0.011Kg, the weight of the conductive plate is 0.021Kg, the total weight of the silver-copper assembly is 0.065Kg; the specific heat capacity of silver Ag is 234J / kg; the specific heat capacity of copper Cu is 390J / kg; the brazing temperature is selected 770-900°C, put the above parameters into the formula to calculate:

[0101] The theoretical power of the silver-copper weldment is 6.8-7....

Embodiment 2

[0138] Welding between dissimilar metals with different thicknesses (copper, iron and silver brazing):

[0139] The processing object is a contact assembly produced by a company producing AC contactors, which is an iron copper plating tank with a conductive plate welded in the middle and a silver contact welded at both ends of the iron copper plating tank surface.

[0140] According to the model of embodiment 1, the contact bridge and contact welding process and the high-frequency induction brazing results of the following AC contactors are counted: the iron copper plating grooves, silver contacts, and conductive plates of different thicknesses and specifications are substituted into The above formula calculates the high-frequency welding process parameters; in addition, the copper tube is bent into a plurality of high-frequency coils corresponding to the product with a gap of 1-2mm and matching shape.

[0141] Table 4: Comparison of basic process parameters of high-frequency ...

Embodiment 3

[0154] High-frequency brazing of AC contactor contacts

[0155] According to the above model of embodiment 1, the welding process and high-frequency induction brazing results of the contact bridge and contacts of the following AC contactors are counted:

[0156] Specification 3:

[0157] U-shaped contact bridge: silver contact 18mm×13mm×1.7mm;

[0158] T3, Y4 contact plate 18mm×55mm×18mm×5;

[0159] Brazing material Bag30CuZn sheet: 0.2mm×13mm×18mm×R15,

[0160] Flux FB303P paste, all surfaces are coated before welding;

[0161] Magnetic Ring Diameter: Pressure: 0.2Mpa; series high-frequency coil:

[0162] Welding weight of silver contact and contact plate: 0.098kg;

[0163] Theoretical required power: 8.1746-9.555KW; actual required power: 12.56-14.7KW,

[0164] Welding current 47-50A; welding time 18-23s; holding current 38-41A; holding time 50-60s;

[0165] Specification 4:

[0166] U-shaped contact bridge: silver contact 22mm×17mm×2.5mm;

[0167]T3, Y4 contact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com