Measuring tool and method used for measuring height from end surface of conical bearing outer ring to joint surface

A technology of the end face of the outer ring and tapered bearings, applied in the field of measurement, can solve the problems of deviation in measurement results, large measurement height, and reduced service life of the transmission, achieving accurate and scientific data, eliminating deflection, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

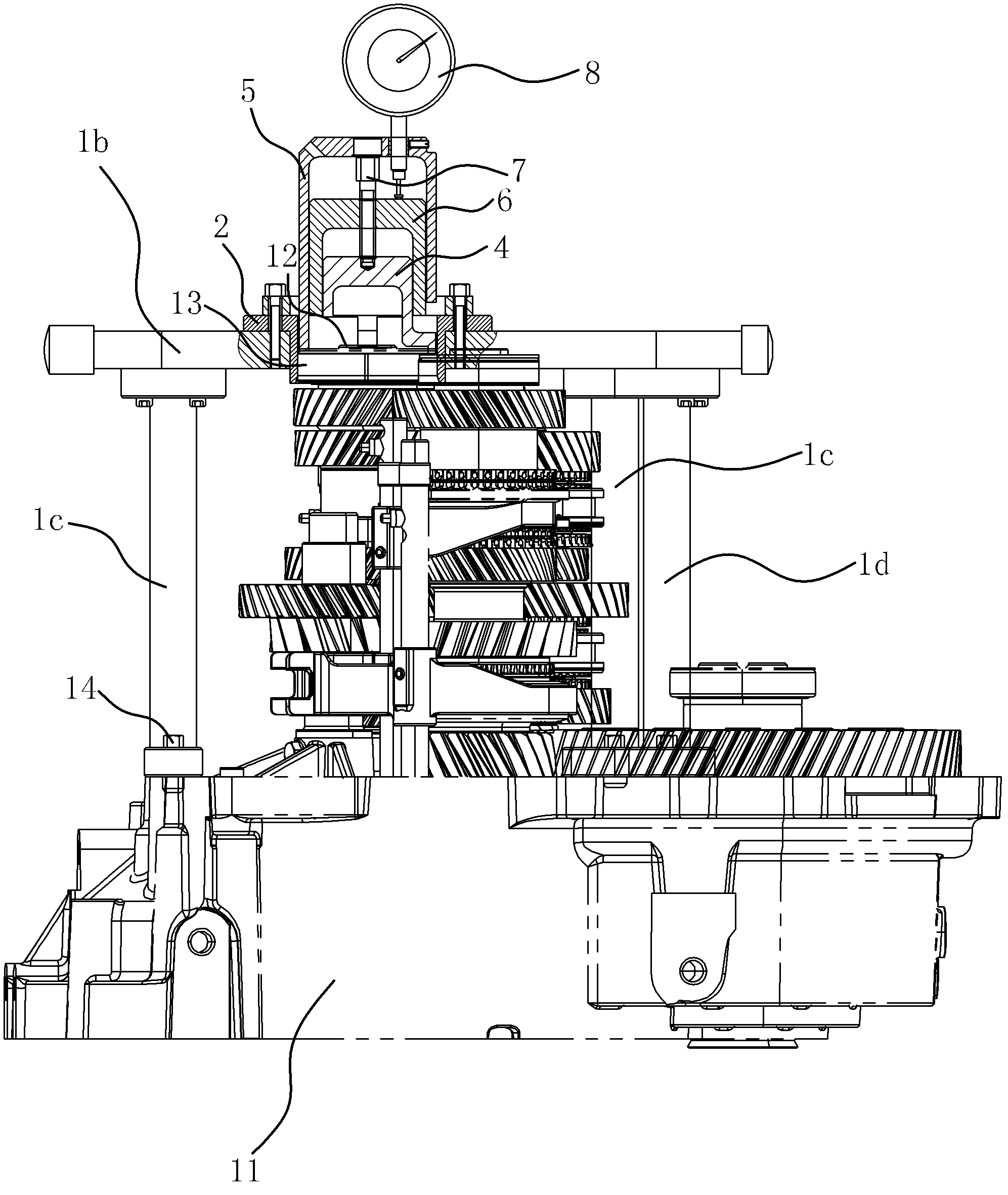

[0050] like image 3 As mentioned above, the transmission includes a front housing 11 and a rear housing buckled with the front housing 11, and both the front housing 11 and the rear housing have joint surfaces. When the transmission is assembled, components such as the differential gear assembly and the input shaft assembly are first positioned on the front housing 11, and then the rear housing is covered. There are several positioning holes on the joint surface of the front housing 11 .

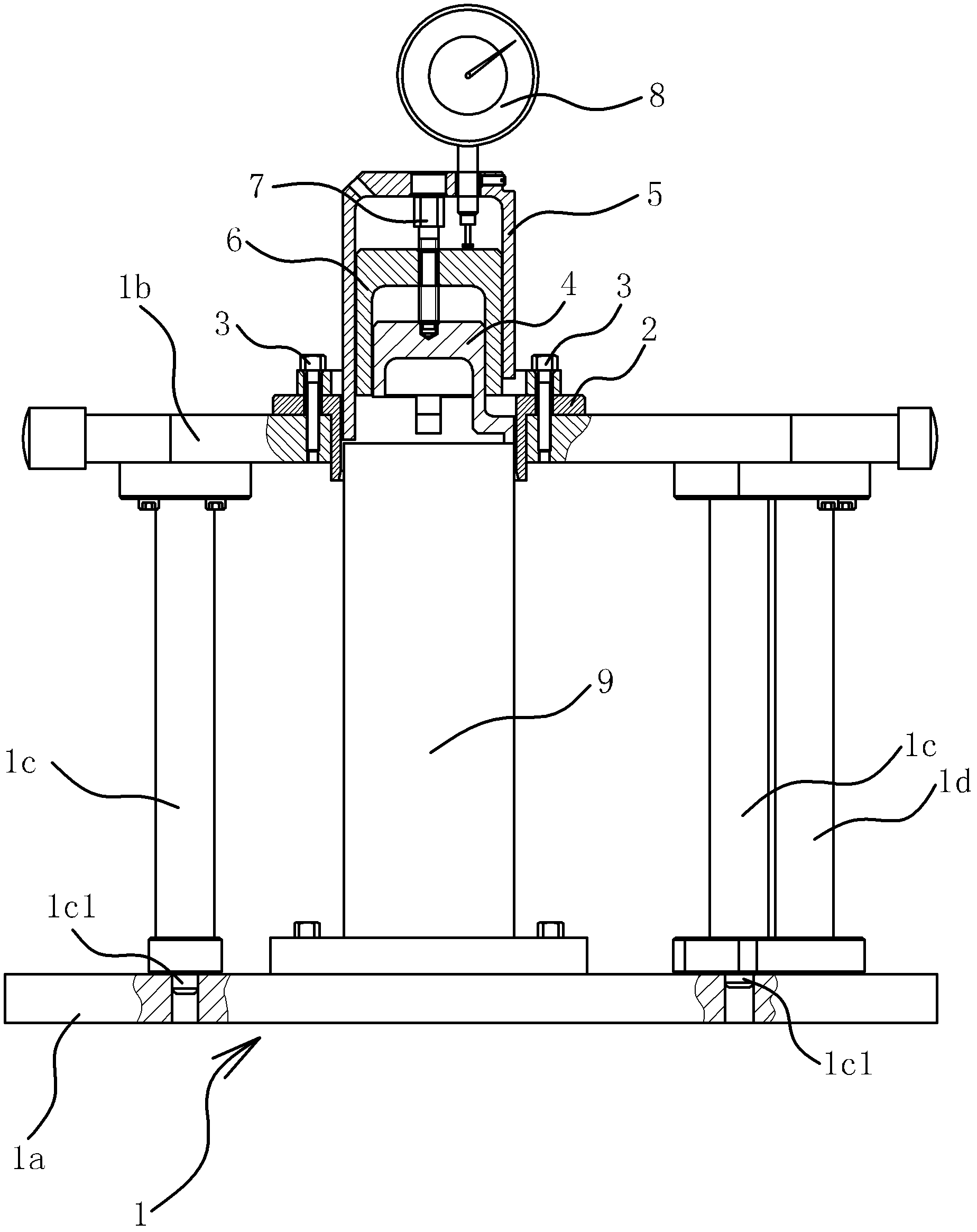

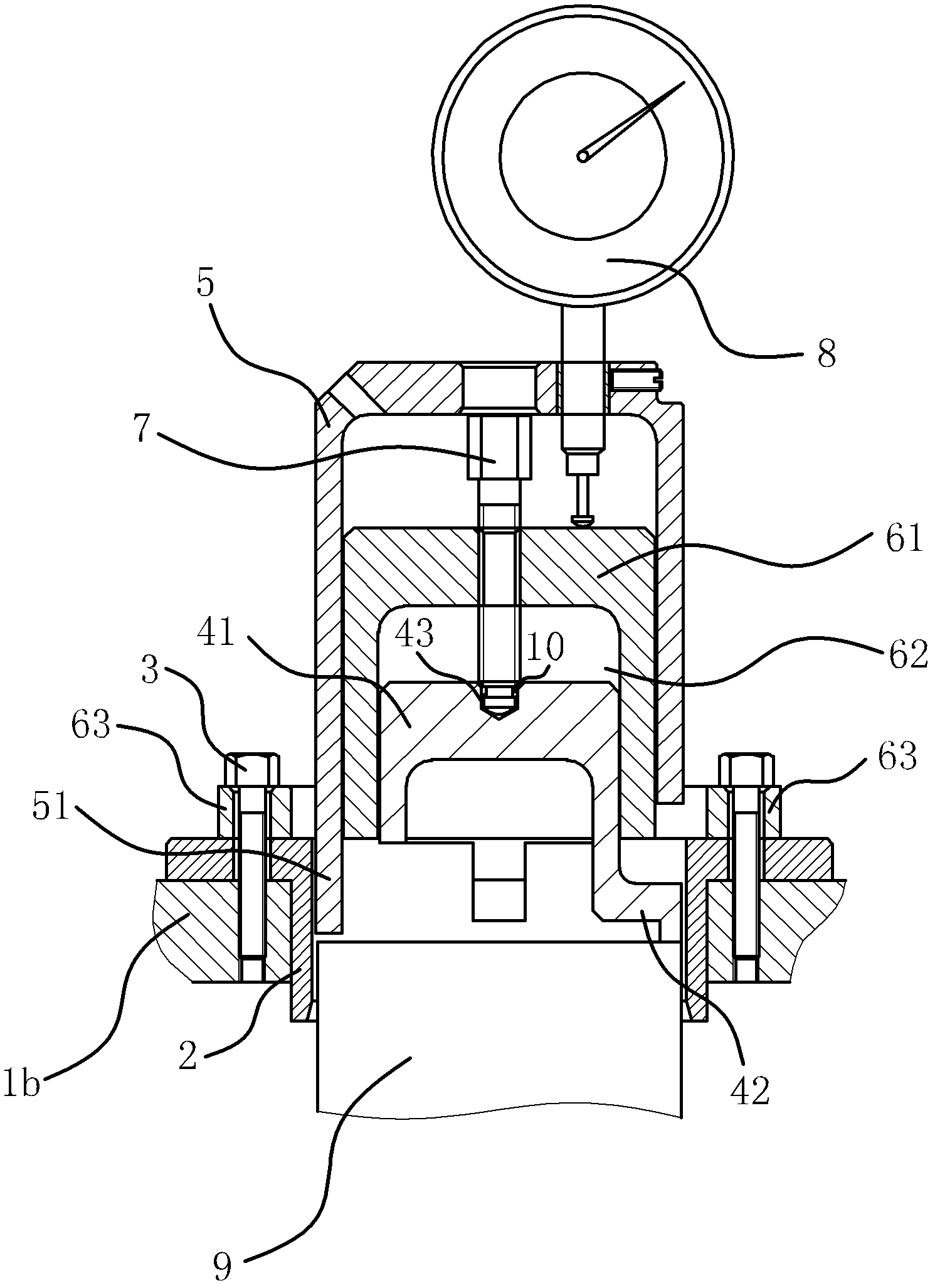

[0051] like figure 1 and figure 2 As shown, the measuring tool for measuring the height from the end surface of the outer ring 13 of the transmission tapered bearing to the joint surface includes a pressing member 4, a positioning b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com