Detachable plate shell type heat exchanger

A plate-and-shell heat exchanger technology, applied in the field of detachable plate-and-shell heat exchangers, can solve the problem of reducing the heat-exchange capacity of the plate-and-shell heat exchanger, difficult to restore the heat-exchange effect, and inability to replace the heat-exchange plate bundles and other problems, to achieve the effect of reducing voids, preventing short circuits, and improving heat exchange effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

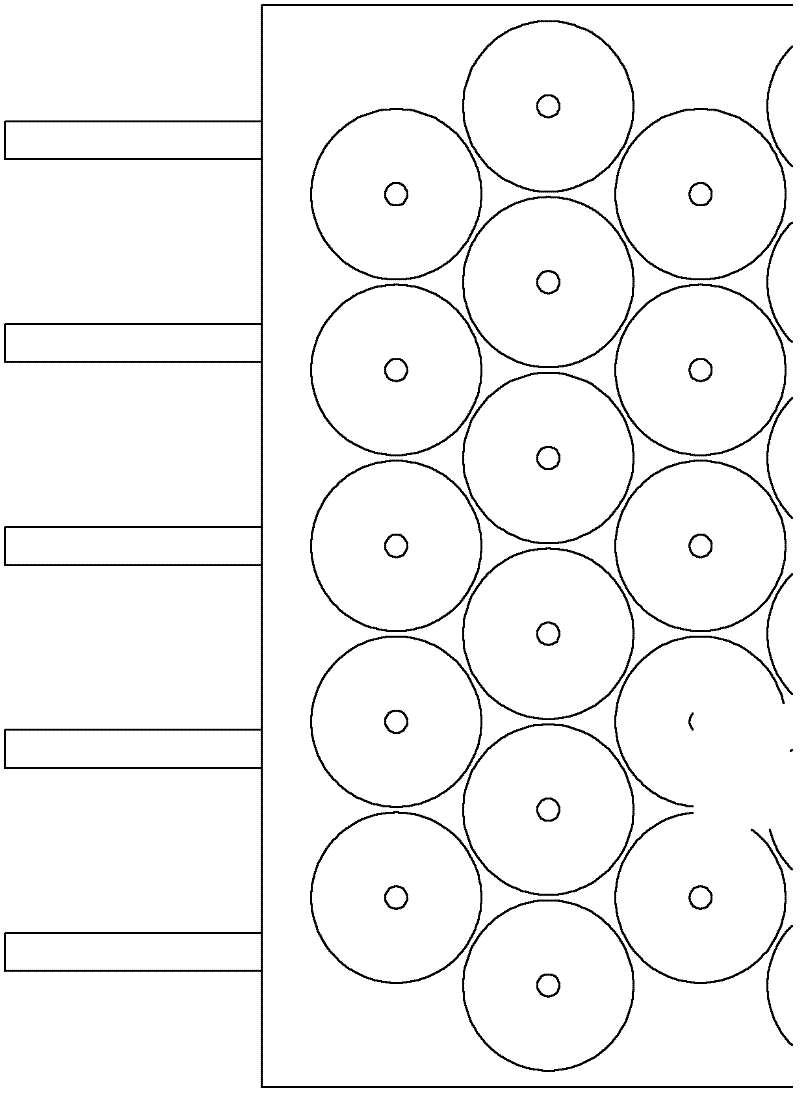

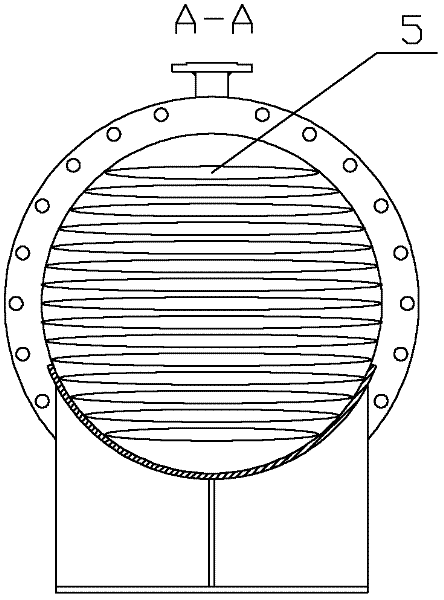

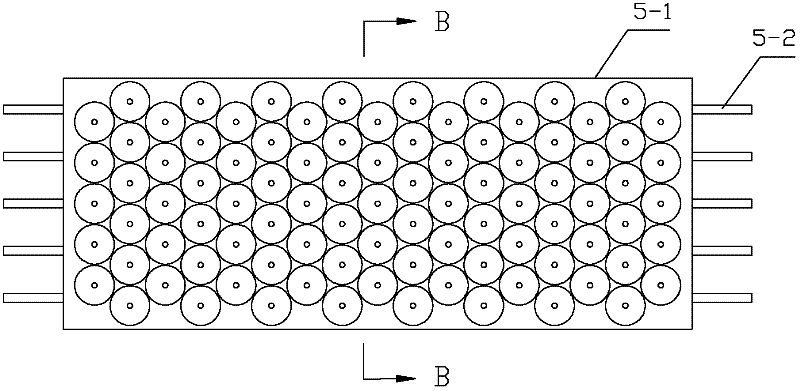

[0042] Such as figure 1 As shown, a detachable plate and shell heat exchanger includes a shell 4, a tube box 1, an inner tube sheet 6, an outer tube sheet 7, and a heat exchange plate bundle installed in the shell. The shell 4 has two Each end is provided with a pipe box 1. The inner tube plate 6 and the outer tube plate 7 are stacked together, located between the tube box 1 and the shell 4, and fixed together by two flanges 2 and bolts, and a gasket is installed between the two flanges 2 slice 9. A plate bundle composed of parallel plates 5 is arranged between the tube plates on both sides, and the plates 5 are arranged at equal intervals, and its two ends are fixed on the tube plates on both sides through plate tubes 5-2, and the plates 5 and The pipe box 1 is connected, and the shell 4 is provided with shell-side inlet and outlet connecting pipes 3-1 and 3-2, and the pipe box 1 is provided with board-side inlet and outlet connecting pipes 8-1 and 8-2. Such as figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com