Superhigh strength cast steel, and preparation method and welding process thereof

An ultra-high strength, welding process technology, applied in the direction of manufacturing tools, welding equipment, and process efficiency improvement, can solve problems such as low strength, and achieve the effect of improving comprehensive mechanical properties, excellent welding performance, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

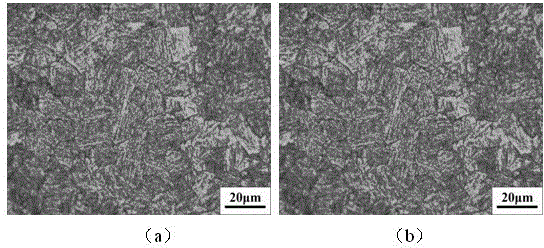

Image

Examples

Embodiment 1

[0051] The preparation and use method of ultra-high-strength cast steel includes the following smelting, pouring, heat treatment and welding processes, and the specific process parameters are:

[0052] (1) Smelting process

[0053] Smelting is carried out in a 200Kg intermediate frequency furnace, and Q235 I-shaped steel scrap and Q10 pig iron with sulfur and phosphorus contents <0.03% respectively are selected as raw materials for smelting. Melt most of the scrap steel 188.16kg and scrap iron 3.78kg, the melting temperature is 1550°C, after all the large materials are cleared, then add 1.91kg of low-carbon ferrochromium FeCr69C0.25 and 2.38kg of molybdenum iron alloy FeMo60-A for melting, 10 minutes before being released from the furnace, carry out slagging treatment, then add 0.65kg of ferrosilicon FeSi75Al1.0-A, 2.17kg of medium carbon ferromanganese FeMn78C2.0, 3 minutes before releasing from the furnace, add 0.37kg of ferrotitanium FeTi30-A, and finally put Add 0.24kg of...

Embodiment 2

[0062] The preparation and use method of ultra-high-strength cast steel includes the following smelting, pouring, heat treatment and welding processes, and the specific process parameters are:

[0063] (1) Smelting process

[0064] Smelting is carried out in a 200Kg intermediate frequency furnace, and Q235 I-shaped steel scrap and Q10 pig iron with sulfur and phosphorus contents <0.03% respectively are selected as raw materials for smelting. Melt most of the scrap steel 187.62kg and scrap iron 4.22kg, the melting temperature is 1580°C, after all the large materials are cleared, then add 2.00kg of medium-carbon ferrochrome FeCr69C1.0 and 2.12kg of molybdenum-iron alloy FeMo70 for smelting. 7min, carry out slagging treatment, then add 0.75kg ferrosilicon FeSi75-A, 2.49kg medium carbon ferromanganese medium carbon ferromanganese FeMn82C1.5, 2min before the furnace, add 0.24kg ferrotitanium FeTi40-A, and finally put Add 0.27kg of final deoxidizer Al and 0.29kg of rare earth ferro...

Embodiment 3

[0073] The preparation and use method of ultra-high-strength cast steel includes the following smelting, pouring, heat treatment and welding processes, and the specific process parameters are:

[0074] (1) Smelting process

[0075] Smelting is carried out in a 200Kg intermediate frequency furnace, and Q235 I-shaped steel scrap and Q10 pig iron with sulfur and phosphorus contents <0.03% respectively are selected as raw materials for smelting. Melt most of the scrap steel 184.64kg and scrap iron 4.45kg first, the melting temperature is 1560℃, after all the large materials are cleared, then add 2.81kg of medium-carbon ferrochrome FeCr55C100 and 2.81kg of molybdenum-iron alloy FeMo55-A for smelting. 10 minutes, carry out slagging treatment, then add 0.97kg of ferrosilicon FeSi65, 3.33kg of medium carbon ferromanganese FeMn84C0.4, 3 minutes before the furnace, add 0.41kg of titanium iron FeTi30-B, and finally put 0.29kg of final deoxidizer at the bottom of the ladle Al and 0.29kg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com